Supercritical water reaction temperature control method, device and supercritical water reactor system

A technology of supercritical water and reaction temperature, which is applied in control/regulation systems, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problem of large external interference in the oxygen circuit, untimely temperature control, and difficulty in ensuring supercritical water reaction. It can improve the stability and safety and reduce the fluctuation range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0063] Hereinafter, the embodiments of the present invention illustrate the technical effects of the present invention through comparative examples and examples respectively. These embodiments are only examples for specifically describing the present invention, and those skilled in the art will know that the scope of the present invention is not limited by these embodiments, comparative examples and test examples.

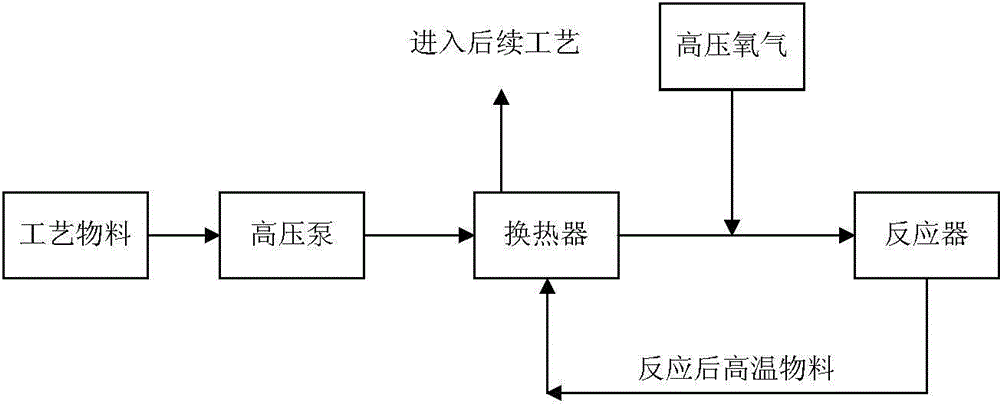

[0064] See figure 1 , Is a process flow diagram of an embodiment of the present invention, specifically:

[0065] Under certain process conditions, the process materials are pumped into the heat exchanger via a high-pressure pump, and the high-temperature products after the reaction in the reactor also enter the heat exchanger to exchange heat with the process materials. The result is The process material is preheated, and the reacted high-temperature product is cooled to enter the subsequent process, and the process material is preheated and enters the reactor together...

Embodiment 1

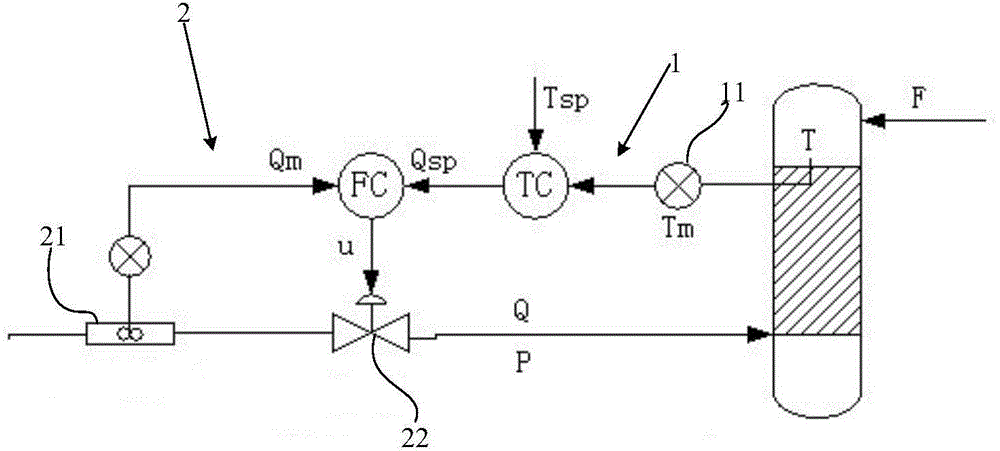

[0071] In the first embodiment, a control method in which the first controller and the second controller are connected in series is used to control the flow of oxygen entering the reactor.

[0072] See Figure 4 , Is the supercritical water reaction temperature control device provided by an embodiment of the present invention, as the working conditions change, see figure 1 , The temperature in the heat exchanger continues to rise, and the flow of oxygen needs to be adjusted. At this time, see Figure 4 , The temperature in the reactor is adjusted in real time through the cascade control of the device, specifically: the first controller 1 obtains the temperature detection value, compares the deviation with the preset temperature, and then sets The flow target value of the amount of oxygen that needs to enter the reactor at this time is calculated, and the flow target value of the oxygen amount is sent to the second controller 2, and the second controller 2 receives the oxygen The o...

Embodiment 2

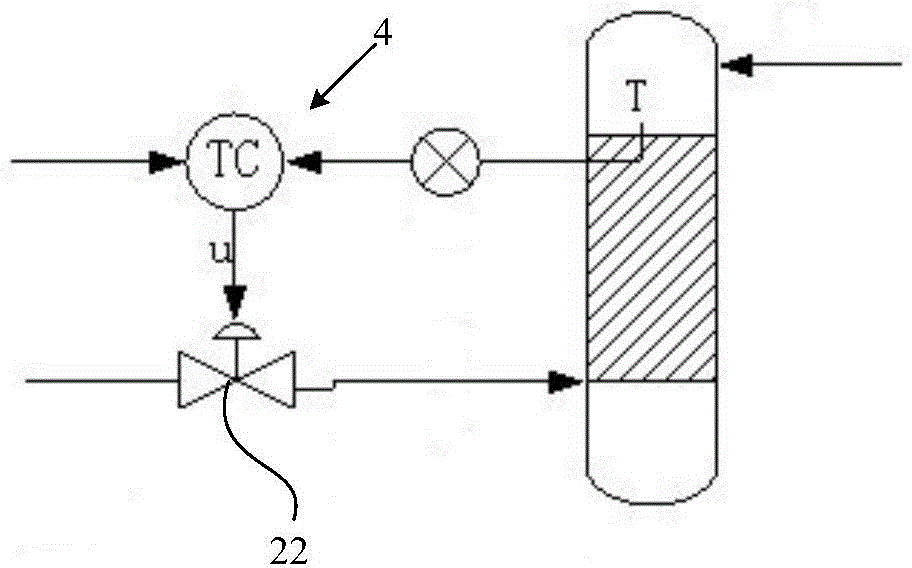

[0074] In the second embodiment, the control method in which the first controller 1 and the second controller 2 are connected in series is used to control the pressure of oxygen entering the reactor.

[0075] See figure 2 , Is the supercritical water reaction temperature control device provided by an embodiment of the present invention. The control process is basically the same as that of Embodiment 1, except that the second controller receives an oxygen pressure gauge 222 The obtained oxygen pressure value, the oxygen pressure value and the oxygen flow value can be converted into each other, but the implementation method is different, which will not be repeated here.

[0076] Through the above-mentioned comparative examples and examples, we have obtained: the introduction of the oxygen quantity control parameter, the deviation comparison between the temperature in the reactor and the preset temperature in the reactor under any working condition, the output is the parameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com