RH furnace circulating pipe and building method thereof

A circulating pipe and one belt technology, applied in the field of RH furnace, can solve the problems of not being widely used, complex processing and assembly process, etc., and achieve the effects of simplifying the production and assembly process, simple and convenient masonry, and convenient filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

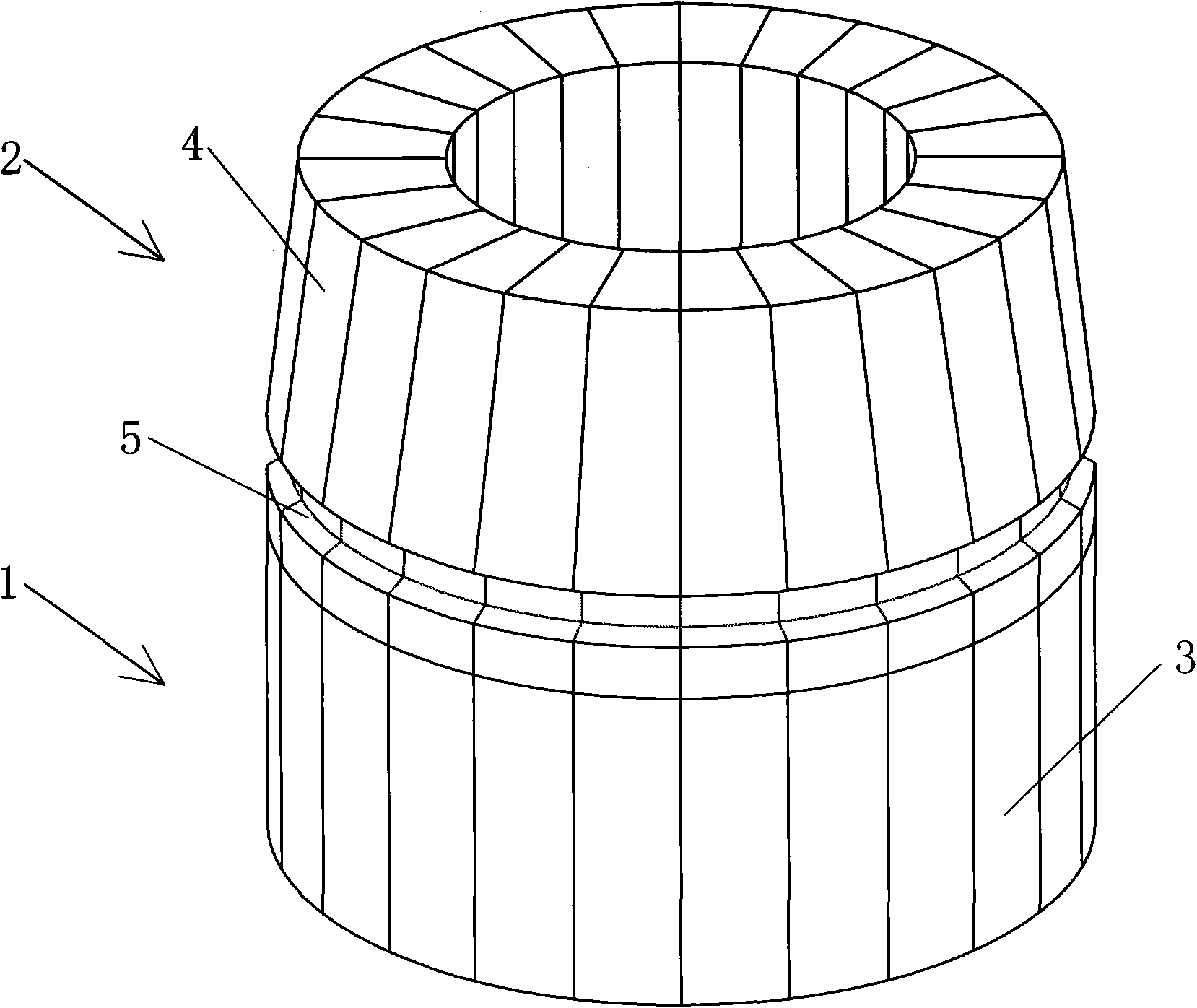

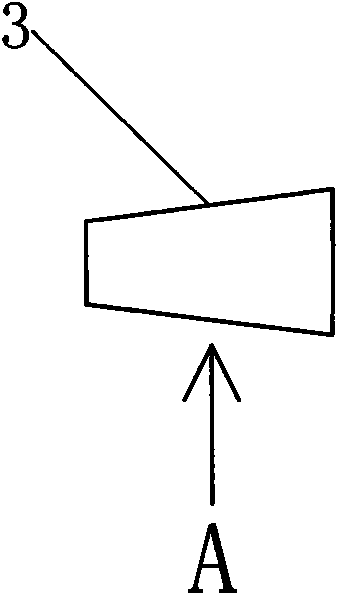

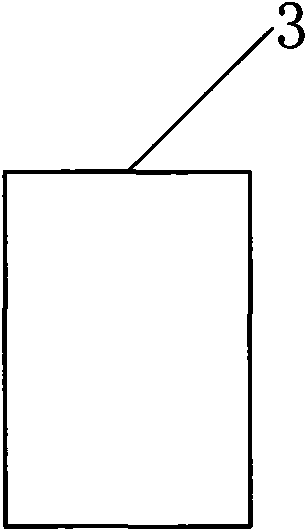

[0028] Embodiment: a kind of RH furnace circulation tube, as Figure 8 As shown, the circulation pipe 12 is cylindrical in shape as a whole, and it is surrounded by a plurality of unit wedge-shaped bricks 11 in an alternating sequence of upright and upside down; Figure 9 As shown, the described unit wedge brick 11 is formed by stacking a long wedge brick 13 and a short wedge brick 14, and the brick shape of the long wedge brick 13 is as follows Figure 10 , Figure 11 As shown, the brick diagram of the short wedge brick 14 is as follows Figure 12 , Figure 13 As shown, a bayonet 15 is provided on the long wedge-shaped brick 13, the lengths of the long wedge-shaped brick 13 and the short wedge-shaped brick 14 are pre-calculated, and the bayonet 15 is exactly half the length of the unit wedge-shaped brick 11, that is, the center position place.

[0029] Thus, the adjacent unit wedge bricks 11 are placed upright and upside down alternately, and the joints 16 of the long wed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com