High conductivity carbon nanotube modified aluminum material and preparation method thereof

A carbon nanotube modification and carbon nanotube technology, which is applied in the field of high-conductivity aluminum materials, can solve the problems of poor bonding between carbon nanotubes and metal substrates, inability to effectively solve dispersion problems, and uneven distribution of carbon nanotubes. Achieve the effect of realizing large-scale industrial production, improving electrical conductivity, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

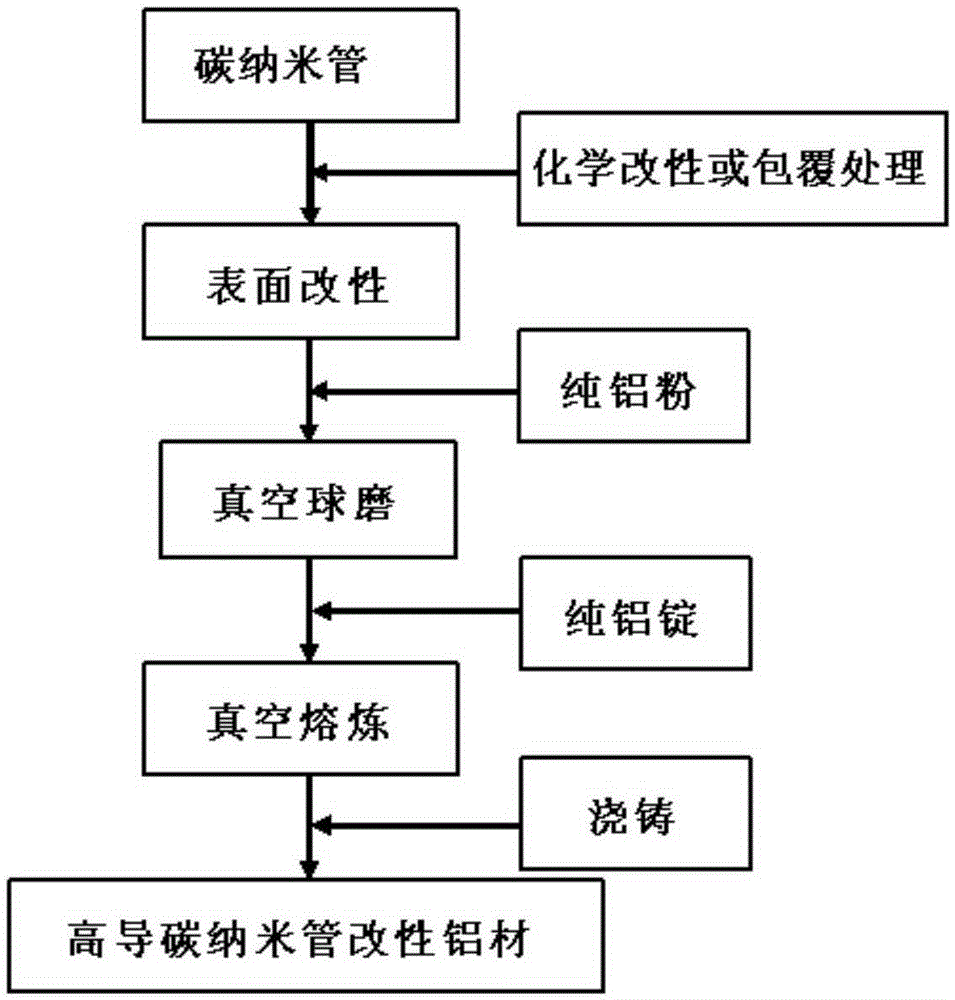

[0024] Such as figure 1 As shown, the preparation method of the highly conductive carbon nanotube modified aluminum material is as follows:

[0025] 1) Using the surface coating process, a layer of aluminum is chemically plated on the surface of the multi-walled carbon nanotubes with a diameter of 40-50nm;

[0026] 2) Mix the multi-walled carbon nanotubes with aluminum deposited on the surface and pure aluminum powder with a particle size of 10-30 μm in a vacuum stirring ball mill. The weight ratio of surface-modified carbon nanotubes to pure aluminum powder is 1:20, and vacuum The degree is 0.5×10 -2 Pa, the speed of the vacuum stirring ball mill is 1000rpm, the ball milling time is 3h, and the ball-to-material ratio is 20:1; the carbon nanotubes are pre-dispersed in the pure aluminum powder to obtain a composite powder that can be used in subsequent processes;

[0027] 3) Take pure aluminum ingots and melt them in a vacuum melting furnace to obtain molten aluminum. The vac...

Embodiment 2

[0029] Such as figure 1 As shown, the preparation method of the highly conductive carbon nanotube modified aluminum material is as follows:

[0030] 1) Using the surface coating process, a layer of copper oxide is chemically plated on the surface of the multi-walled carbon nanotubes with a diameter of 30-40nm;

[0031] 2) Mix multi-walled carbon nanotubes with copper oxide deposited on the surface and pure aluminum powder with a particle size of 20-30 μm in a vacuum stirring ball mill. The weight ratio of surface-modified carbon nanotubes to pure aluminum powder is 1:30. Vacuum degree is 0.5×10 -2 Pa, the speed of the vacuum stirring ball mill is 1500rpm, the ball milling time is 4h, and the ball-to-material ratio is 25:1; the carbon nanotubes are pre-dispersed in the pure aluminum powder to obtain a composite powder that can be used in subsequent processes;

[0032] 3) Take pure aluminum ingots and melt them in a vacuum melting furnace to obtain molten aluminum. The vacuum ...

Embodiment 3

[0034] Such as figure 1 As shown, the preparation method of the highly conductive carbon nanotube modified aluminum material is as follows:

[0035] 1) Using the surface coating process, a layer of polyethylene glycol is coated on the surface of single-walled carbon nanotubes with a diameter of 1-2nm;

[0036] 2) Mix single-walled carbon nanotubes coated with polyethylene glycol and pure aluminum powder with a particle size of 4-8 μm in a vacuum stirring ball mill, and the weight ratio of surface-modified carbon nanotubes to pure aluminum powder is 1 : 25, the vacuum degree is 0.5×10 -2 Pa, the speed of the vacuum stirring ball mill is 800rpm, the ball milling time is 2h, and the ball-to-material ratio is 30:1; the carbon nanotubes are pre-dispersed in the pure aluminum powder to obtain a composite powder that can be used in subsequent processes;

[0037] 3) Take pure aluminum ingots and melt them in a vacuum melting furnace to obtain molten aluminum. The vacuum degree of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com