Rolling thrust device for cone bit bearing

A roller cone bit and thrust technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of restricting the extension of bearing life, bit failure, high heat generation, etc., to prolong the service life, avoid mud bag, The effect of avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

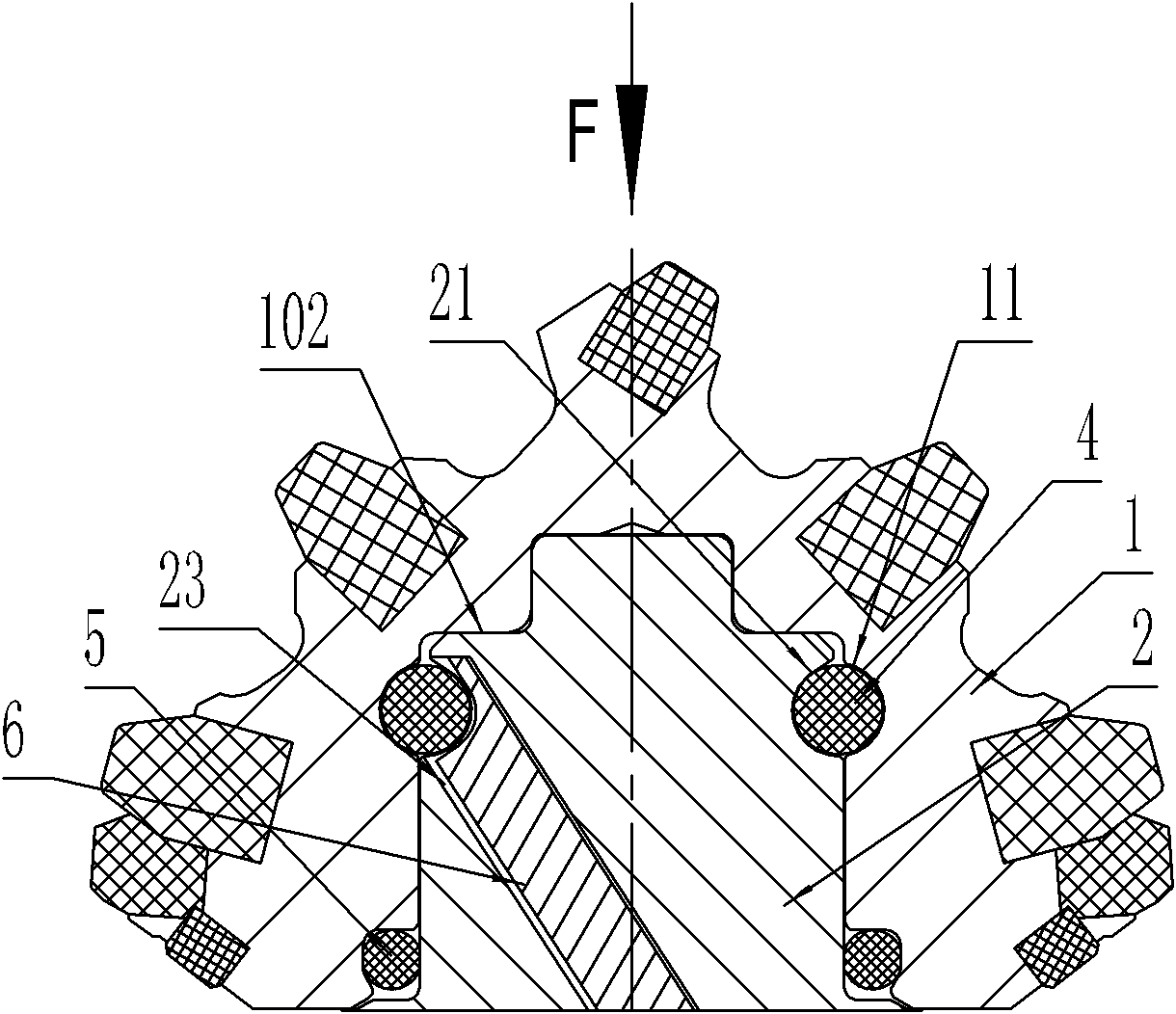

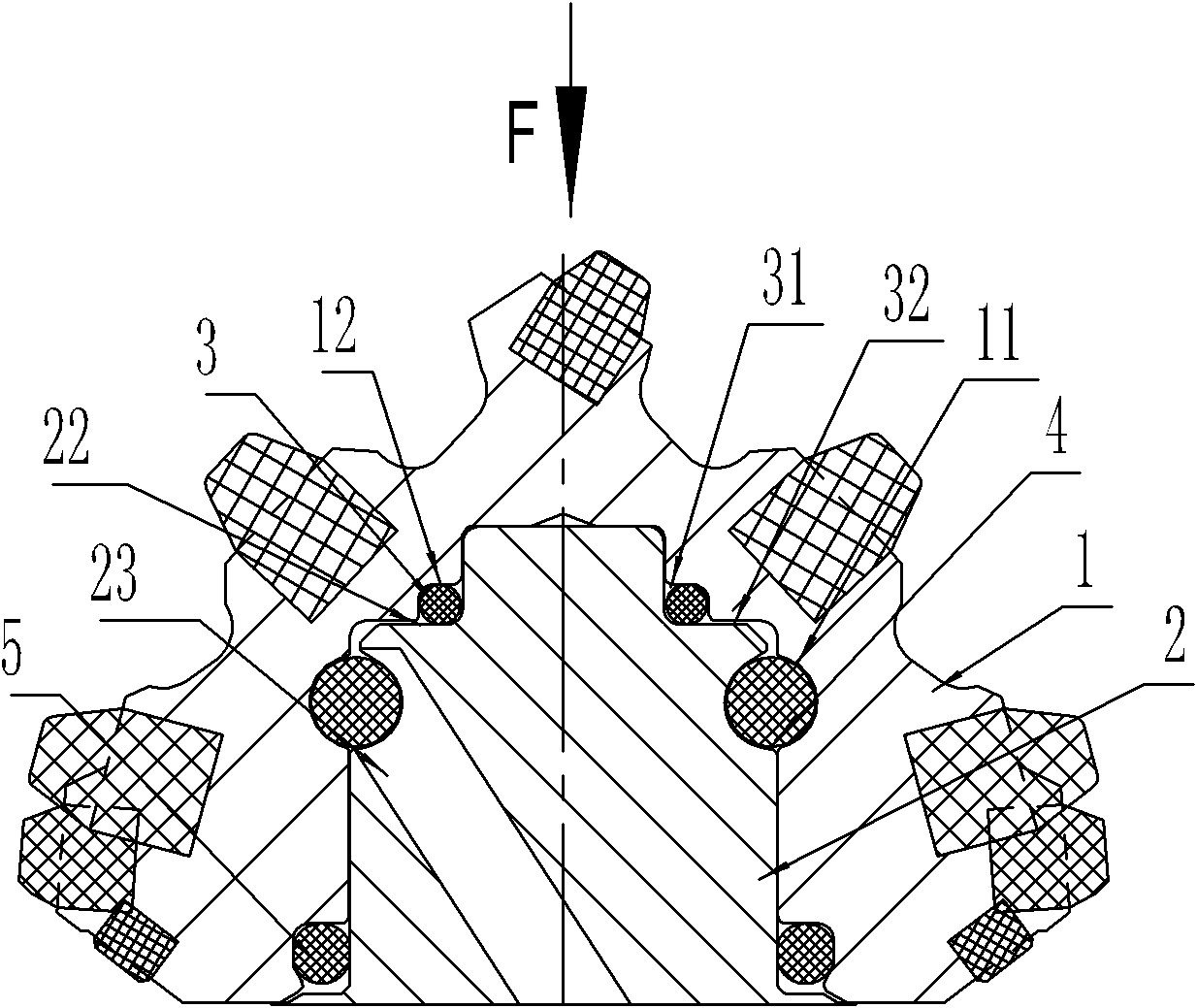

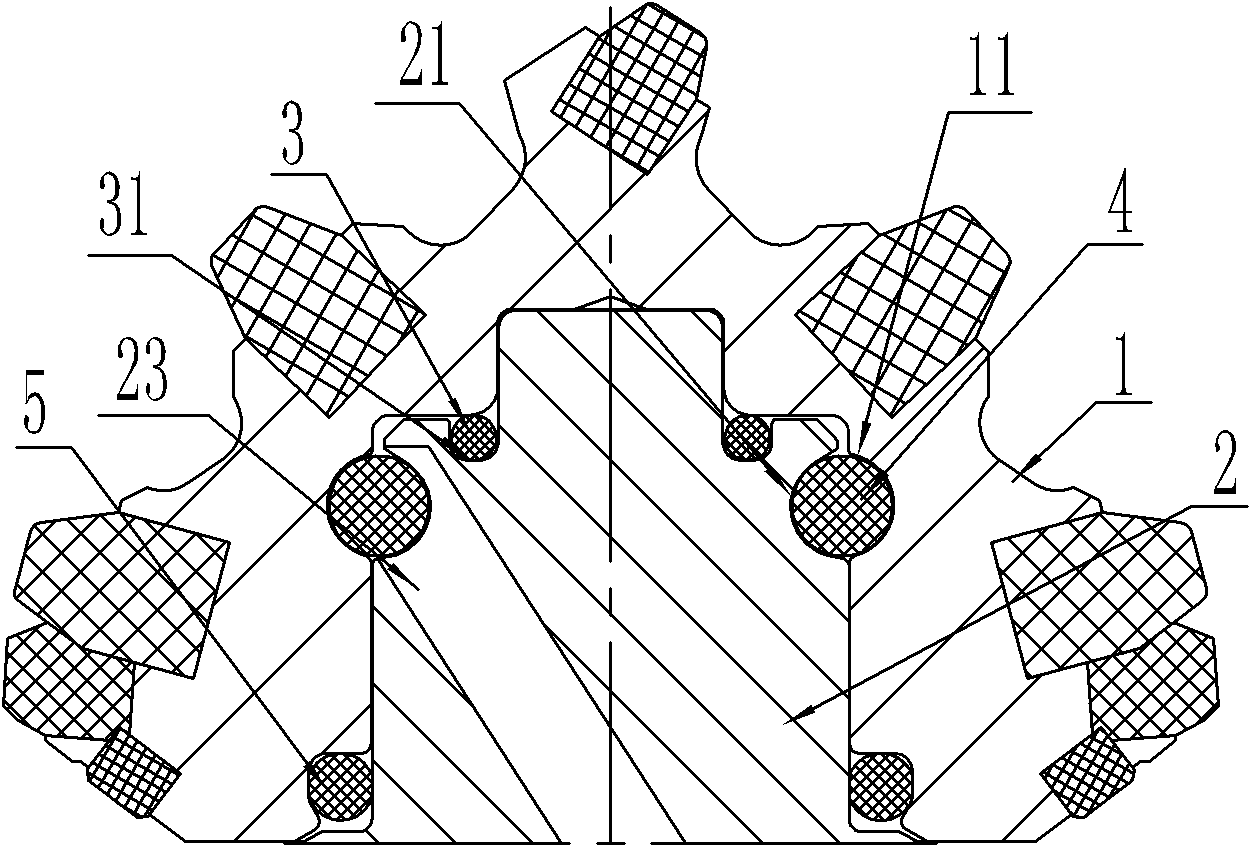

[0010] In order to better understand the solution of the present invention, it is necessary to make a brief introduction to the traditional roller cone bit which is slidingly fitted with the thrust surface. figure 1 is a cross-sectional view of the sliding thrust surface of a traditional roller cone bit, such as figure 1 As shown, after the "O"-shaped sealing ring 5 is installed in the cone 1, it is assembled with the tooth palm shaft 2, and the locking steel ball 4 is inserted into the cone locking steel ball track 11 and the tooth palm through the plug hole 23. Between the locking steel ball raceways 21, the plug pin 6 is welded firmly after being packed into the plug pin hole 23, and the locking steel ball 4 is limited in the locking steel ball raceways 11,21. After the locking steel ball 4 is loaded, the axial positions of the cone 1 and the tooth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com