Engine transient air inflow estimation method based on model

An engine and air intake technology, applied in engine control, machine/engine, electrical control, etc., can solve problems such as poor engine charging efficiency change trend accuracy, poor air volume estimation accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

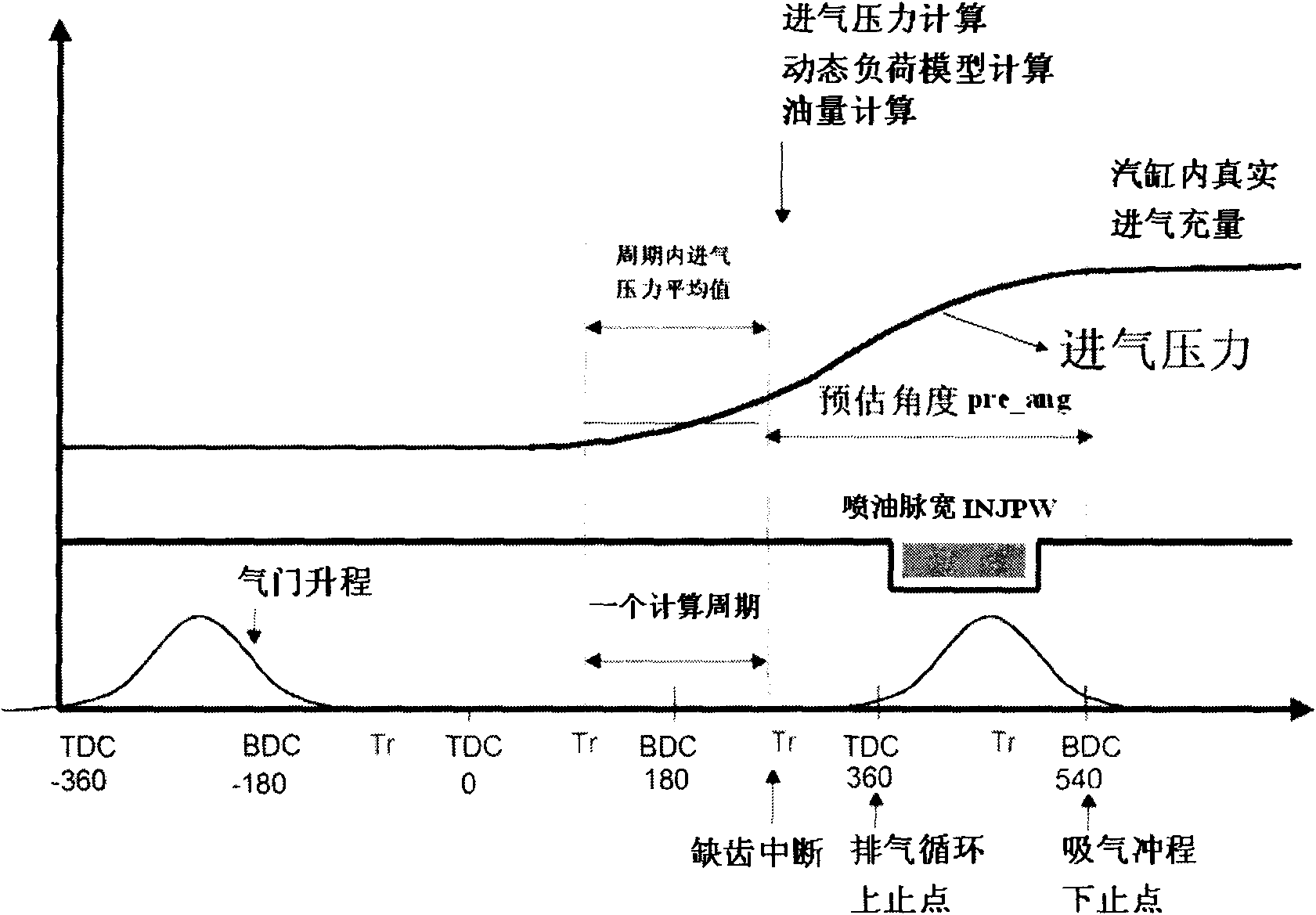

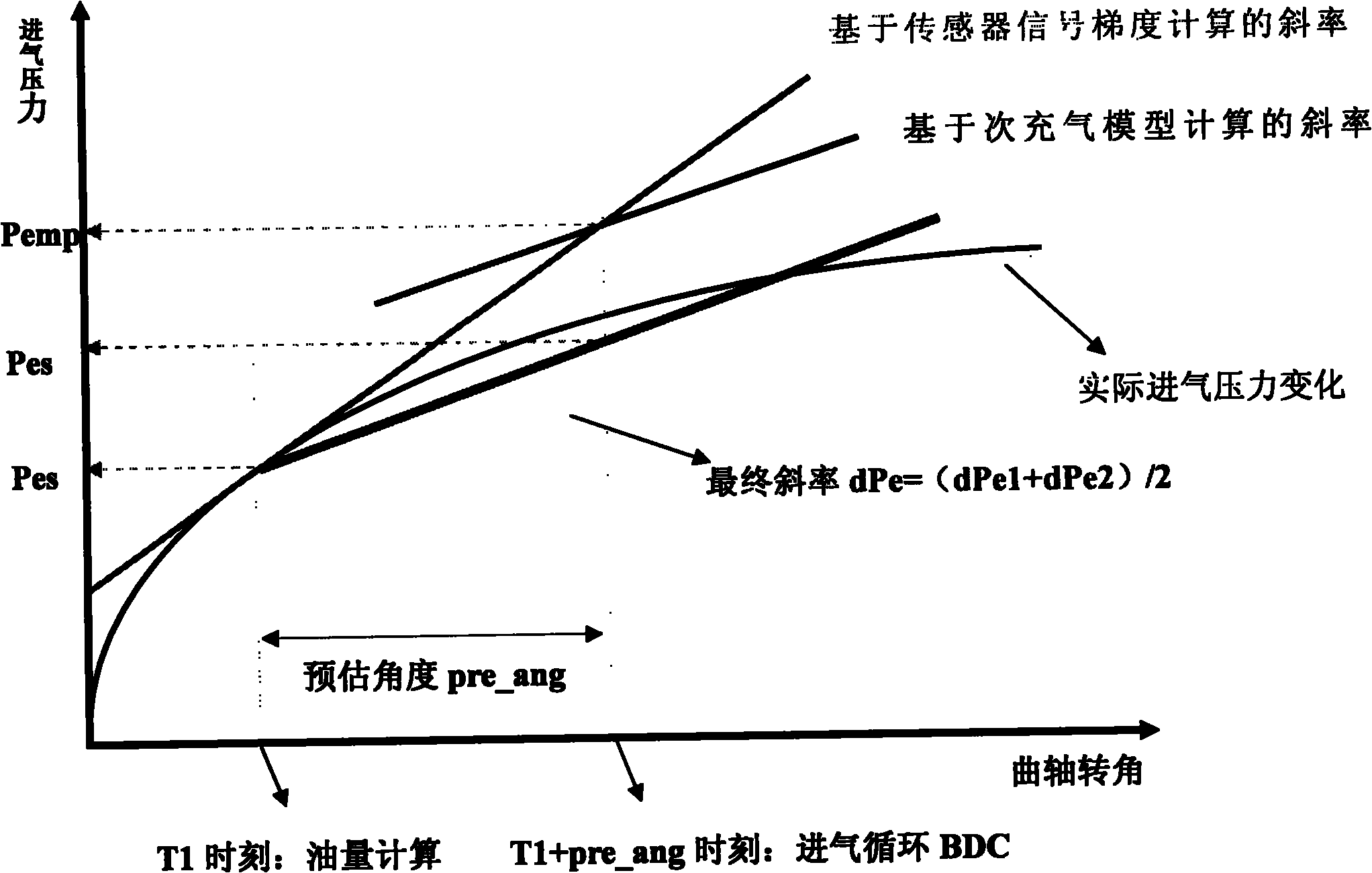

[0049] Below in conjunction with accompanying drawing, the present invention is further described: a kind of model-based engine transient air intake quantity estimation method, it is characterized in that: be made up of following several physical models and computing method; Processing, main charging model based on velocity density method, secondary charging model based on throttle flow characteristics, throttle angle estimation model, intake pipe dynamic load model, and pre-estimation calculation of charge coefficient; the calculation process is sequentially performed in a 10ms task Calculate the secondary charging model, throttle angle prediction model, calculate the current intake pressure, main charging model, intake pipe dynamic load model and charge coefficient prediction model when the missing tooth is interrupted.

[0050] Specifically include the following:

[0051] 1. Define the charge coefficient

[0052] Single-cylinder air intake quality and under standard conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com