Side-seam cyclone low-noise gas pressure-reducing valve

A low-noise, pressure-reducing valve technology, which is applied to valve details, valve devices, and devices for absorbing fluid energy in valves, can solve problems such as unstable operation of equipment, complex structures, and leakage at the packing of pressure-reducing valve groups. Reduced floor space and investment, convenient maintenance and control, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

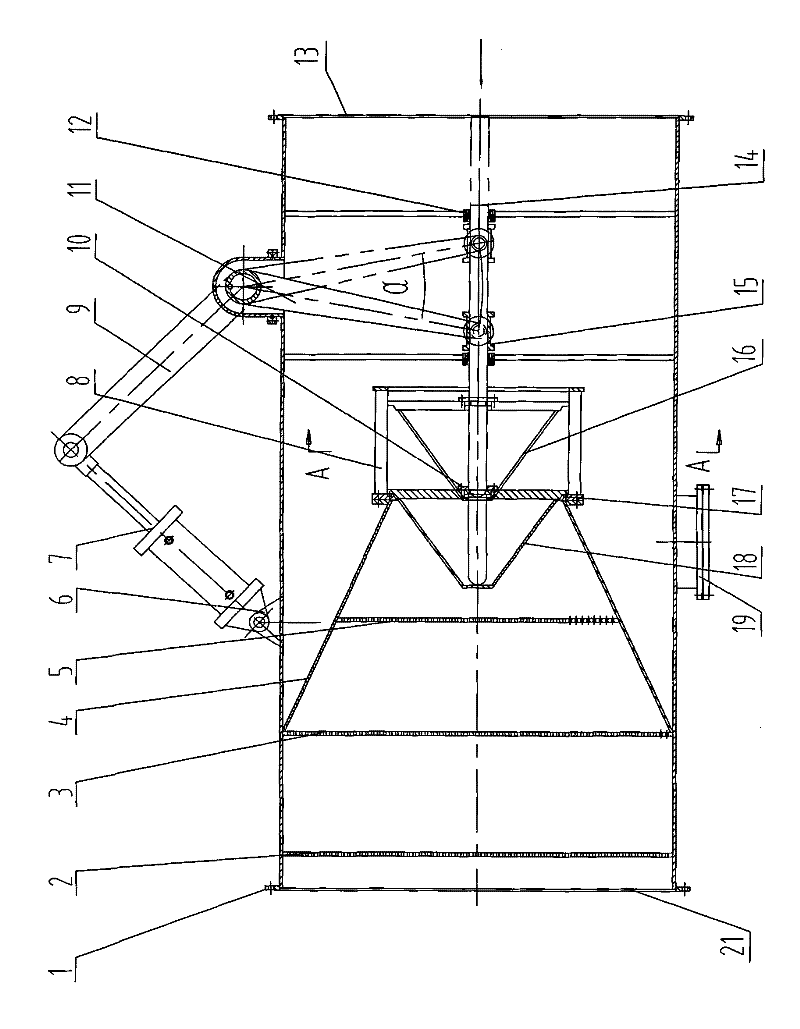

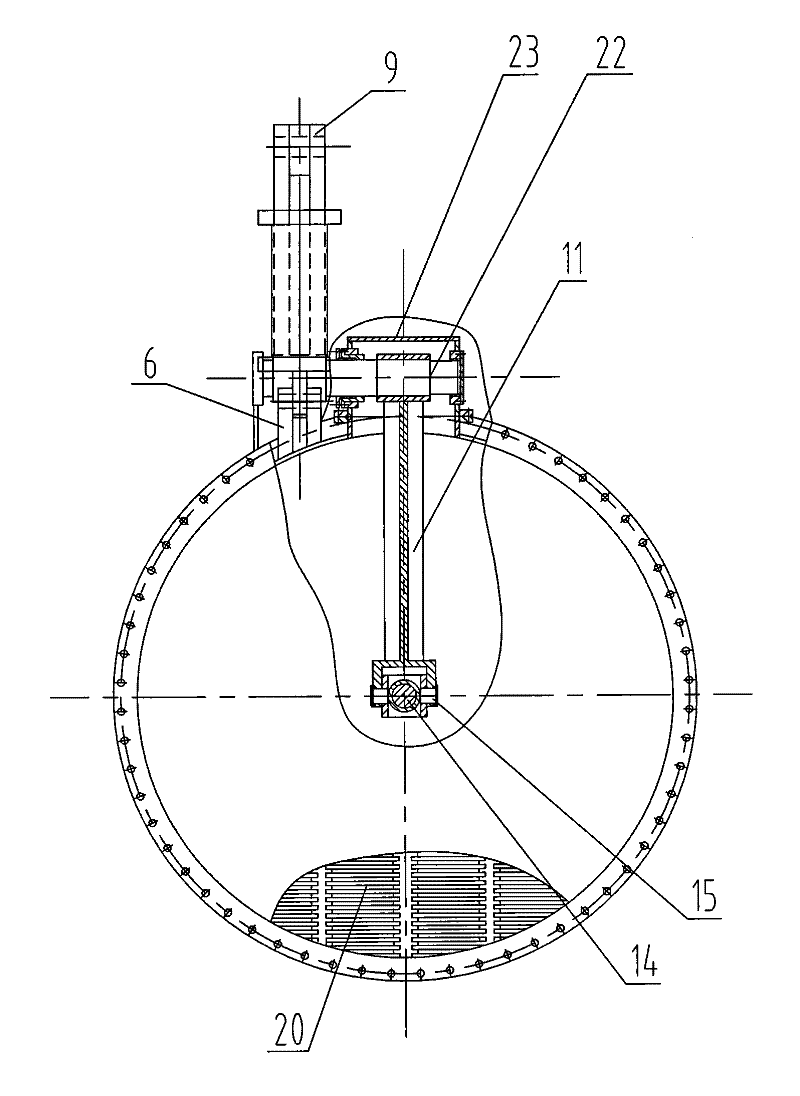

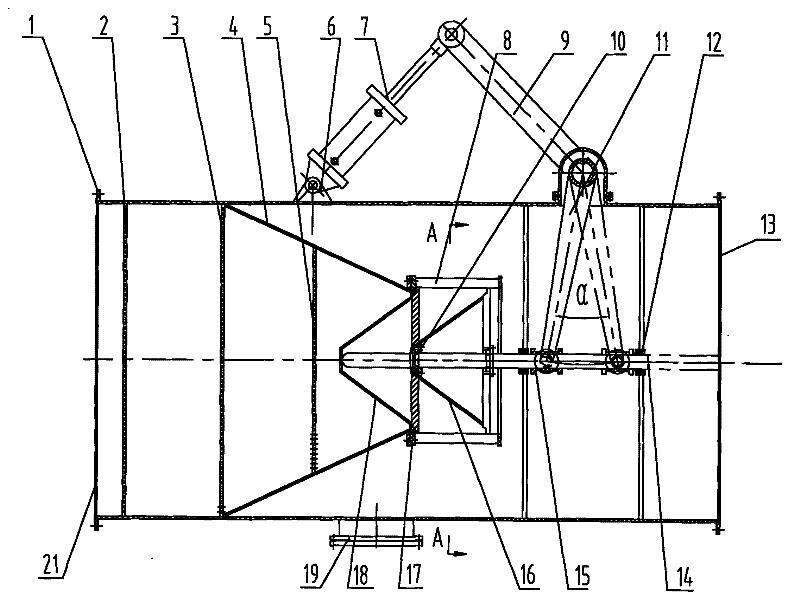

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the side seam swirl low-noise gas pressure reducing valve of the present invention comprises a valve body 1, a valve air inlet 13, a valve air outlet 21, an air inlet section arranged in the valve body 1, and the air inlet The bell valve section connected with the mouth section, the air outlet section connected with the bell valve section, the bell valve spool 18 and the valve seat device 17 are arranged in the bell valve section, and the bell valve spool 18 connected with the bell valve section The valve stem 14, the bell valve umbrella-shaped support 16 that is slidingly connected with the bell valve stem 14, is characterized in that a group of valve stem bracket devices 12 and the bell valve stem 14 are arranged in the air inlet section. Sliding connection, between the valve stem support device 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com