Method for the production of an integrally bladed rotor, and rotor

A technology of integral installation and rotor, which is applied in the direction of supporting elements of blades, manufacturing tools, engine manufacturing, etc., can solve expensive problems and achieve the effect of reducing structural volume and reducing structural volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

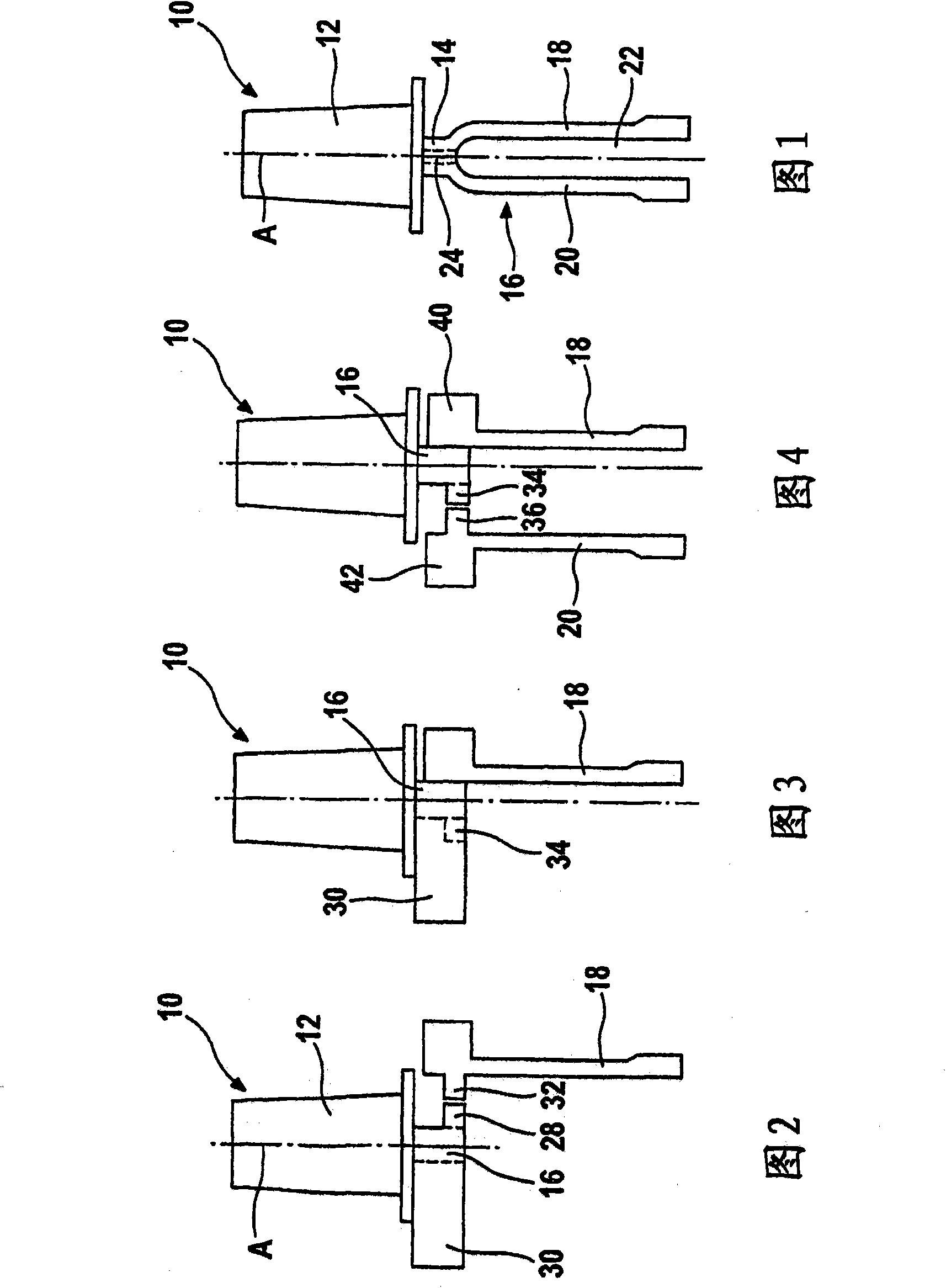

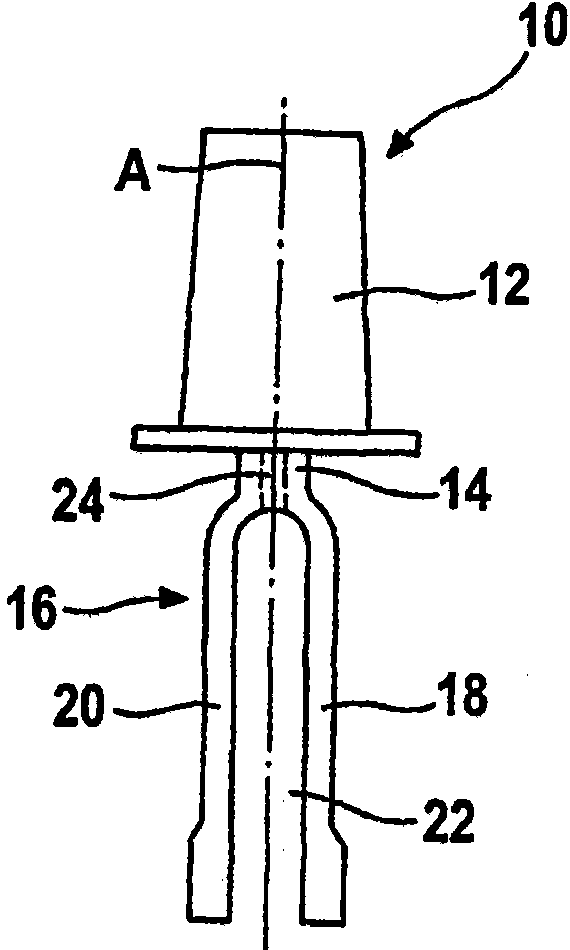

[0028] exist figure 1 An integrally bladed rotor in the form of a gas turbine rotor is shown in half-section in .

[0029] The rotor comprises segments, namely a cascade ring 10 with turbine blades 12 and a ring segment 14 connecting the turbine blades 12 and a rotor carrier.

[0030] The rotor carrier includes a first rotor base body 18 and a second rotor base body 20 . The two rotor base bodies 18 , 20 are fastened to the cascade ring 10 by friction welding.

[0031] as from figure 1 As can be seen, the rotor base bodies 18 , 20 are axially spaced apart from each other, thereby forming a cavity 22 therebetween, which may be part of a cooling channel system that reaches the turbine via some further channels 24 Blade 12.

[0032] The manufacture of the rotor is explained below. Cascade ring 10 is manufactured such that turbine blades 12 are mounted on ring segments 16 by welding, brazing or casting the ring segments. The ring segments 16 are typically made of a differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com