Laminated iron core for rotor

A rotor and iron core technology, which is applied in the field of rotor laminated iron cores, can solve the problems that the thickness of the connecting part 78 is no longer constant, difficult to control, and the thickness is increased, so as to achieve the effects of easy quality management, preventing deformation and improving the quality of the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Next, specific embodiments of the present invention will be described with reference to the drawings to facilitate understanding of the present invention.

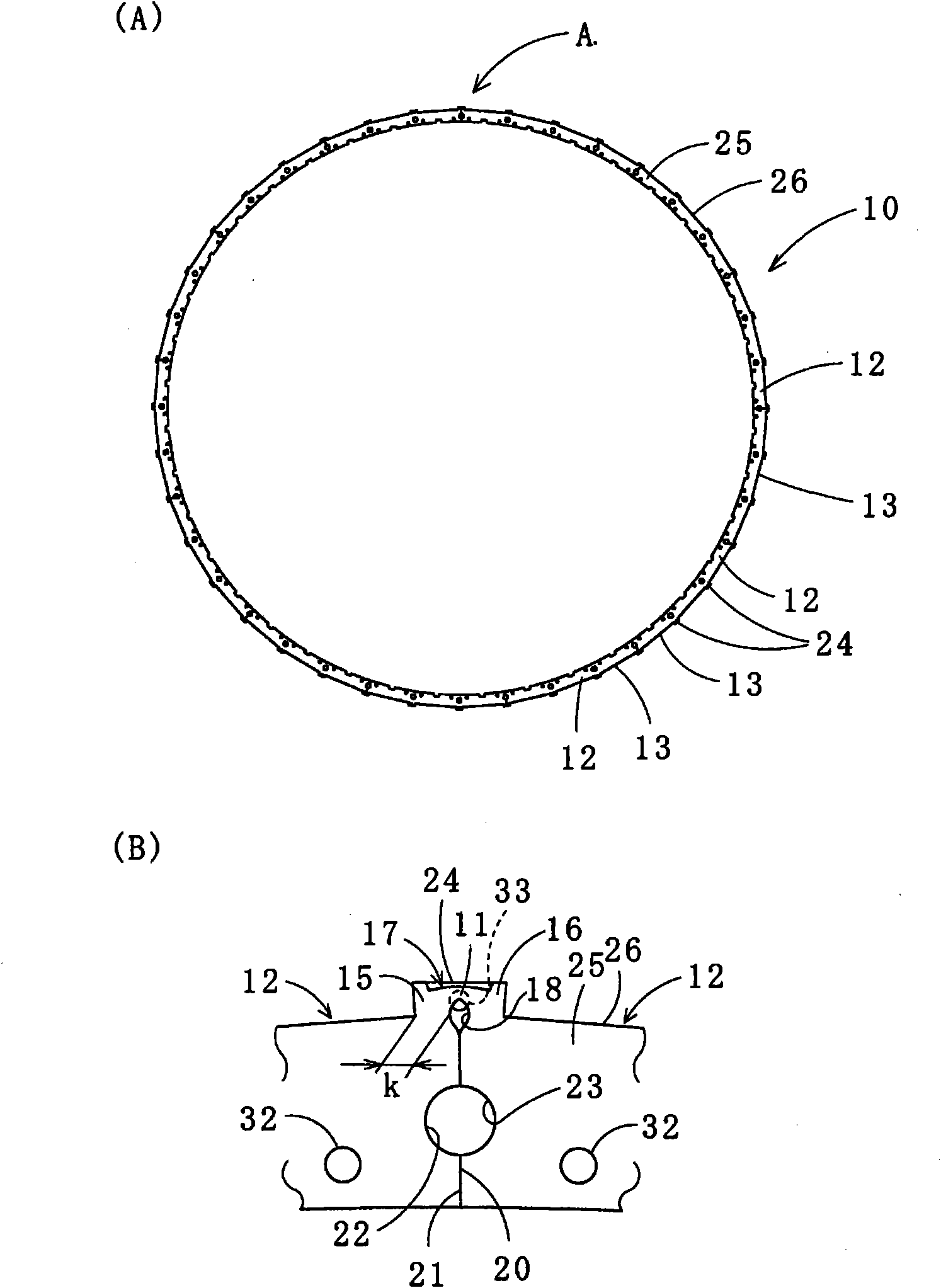

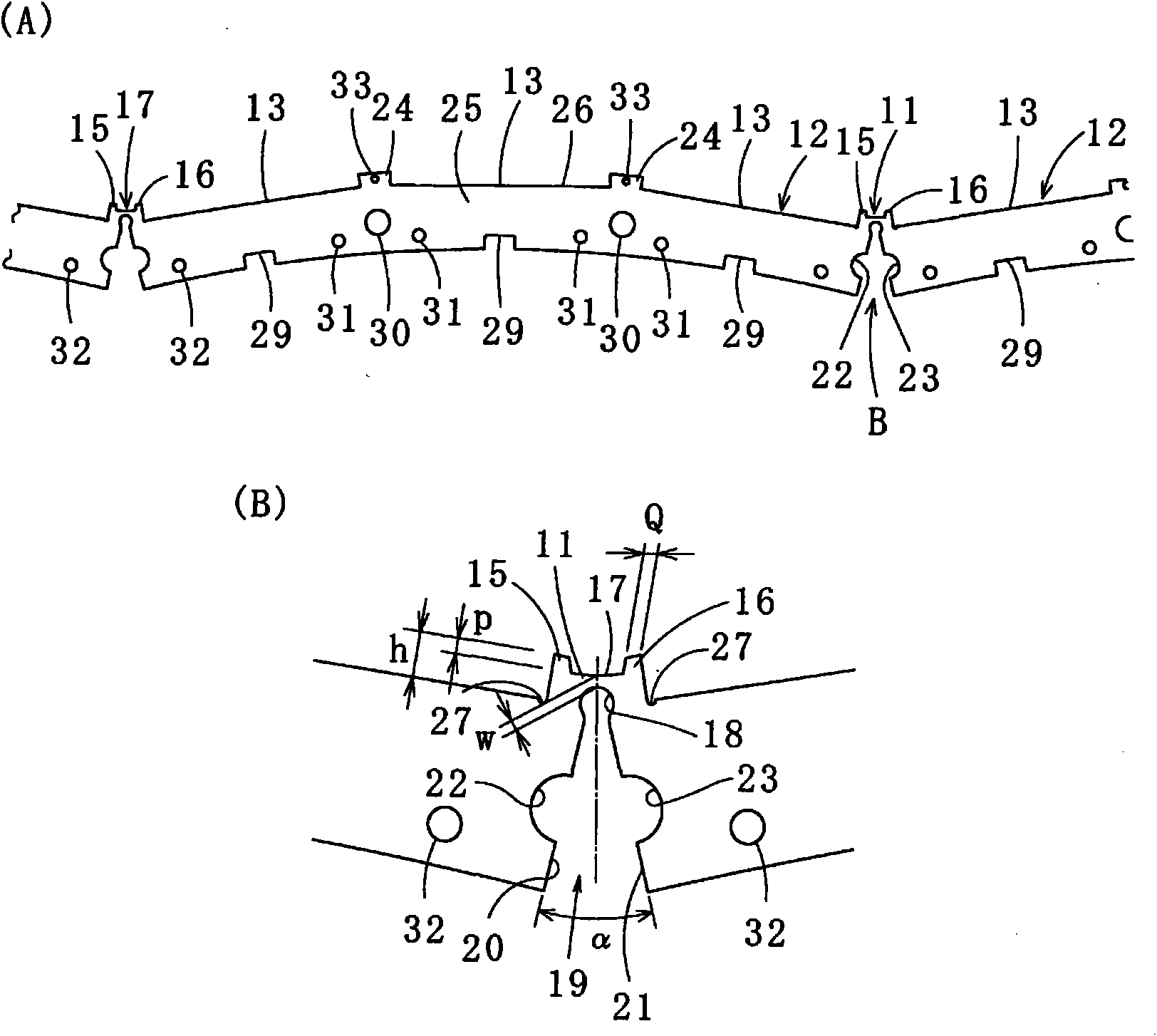

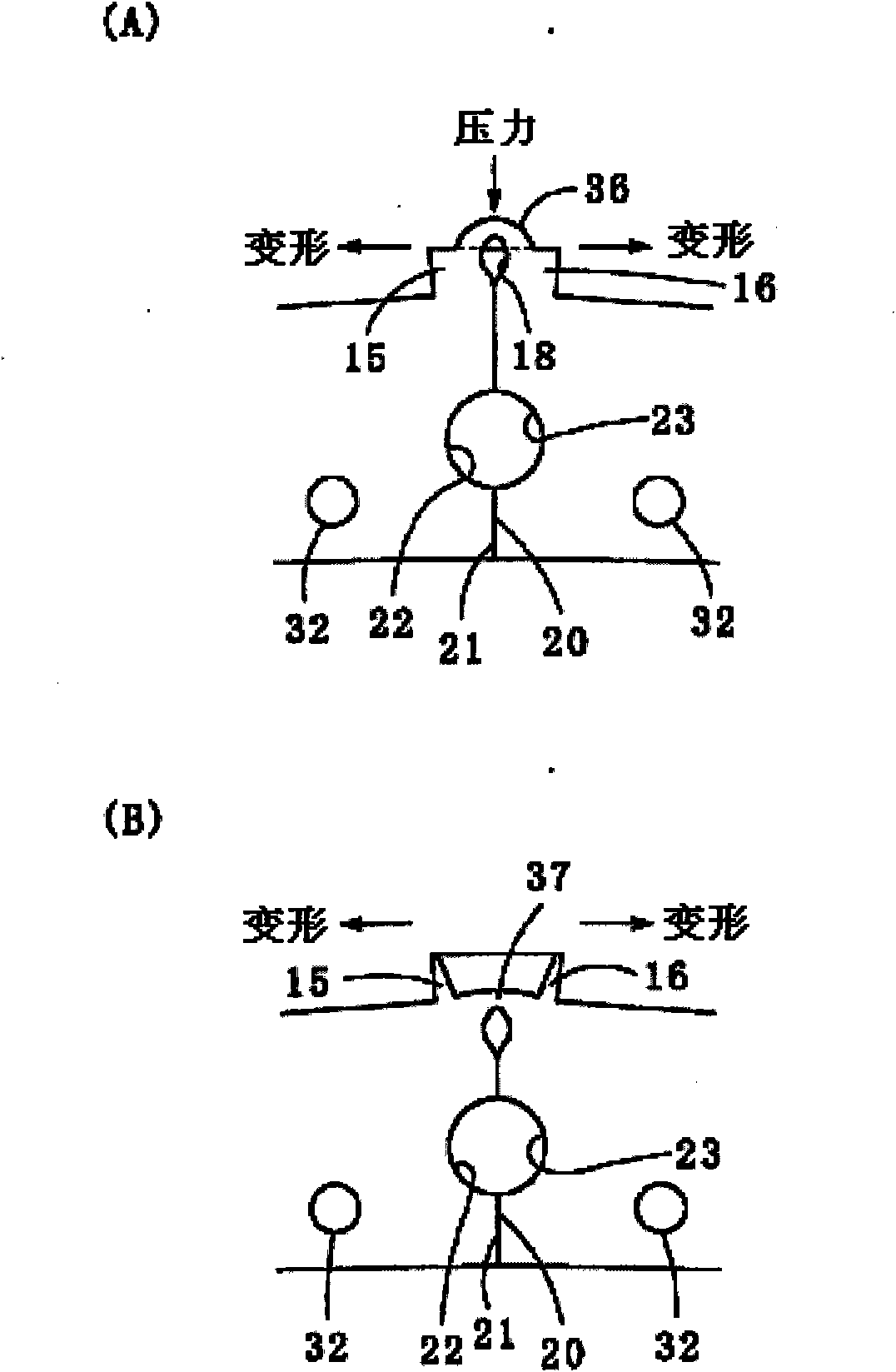

[0038] here, figure 1 (A) is a plan view of a rotor laminated core according to an embodiment of the present invention, and (B) is an enlarged view of arrow A; figure 2 (A) is a partial top view of the band-shaped sector-shaped core pieces connected by the connecting part, and (B) is an enlarged view of the arrow B part; image 3 (A) and (B) are detailed diagrams of the connecting portion of the sector-shaped core pieces of the comparative example; Figure 4 It is a detailed plan view around the connection part.

[0039] like figure 1 (A), (B), figure 2 As shown, the rotor laminated core 10 according to one embodiment of the present invention is a member in which a plurality of arc-shaped sector core pieces 12 connected by connecting portions 11 are laminated by spiral winding. The whole has 40 poles, that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com