Virtual numerical control machine on-line detection system and method

A technology of numerical control machine tools and numerical control systems, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of reducing the efficiency of online detection, cumbersome, and not giving full play to the advantages of online detection, and achieve convenient function expansion , Simplify the operation process and reduce the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

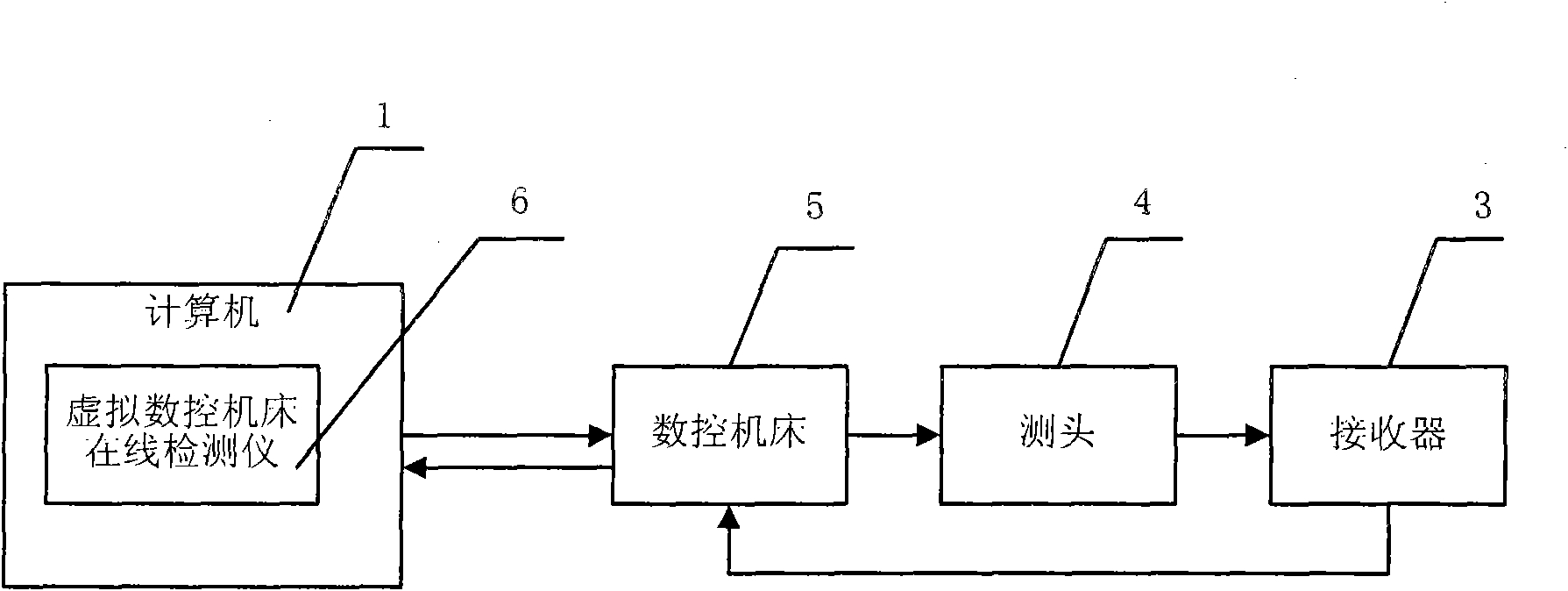

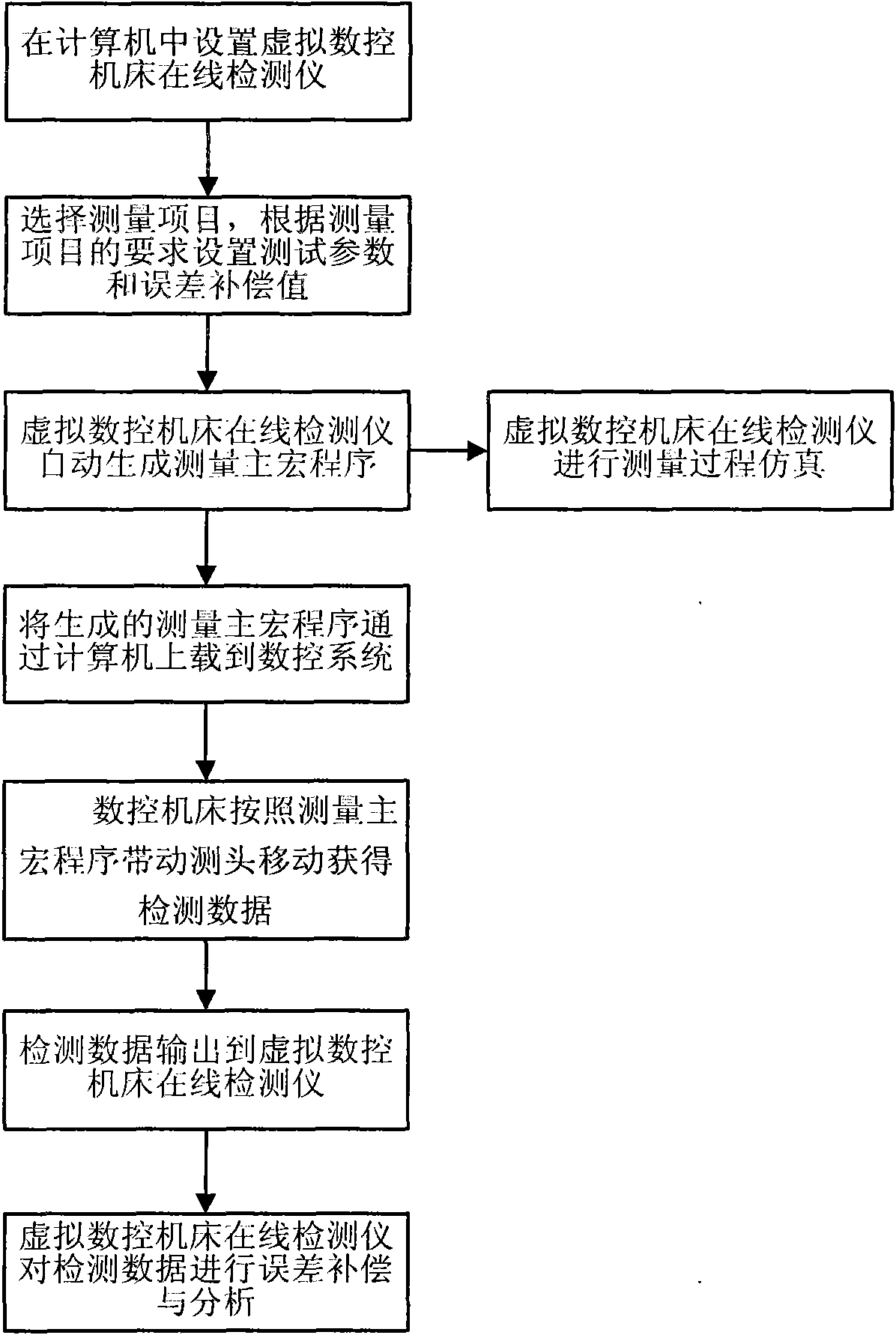

[0054] see figure 1 , a virtual CNC machine tool online inspection system A virtual CNC machine tool online inspection system consists of a computer 1, a probe 4 installed on the tool handle, a receiver 3 matching the probe 4, a CNC machine tool 5, and a virtual CNC machine tool A machine tool online detector 6 is formed, wherein the CNC machine tool 5 includes a numerical control system, and the virtual CNC machine tool online detector 6 is set in the computer 1;

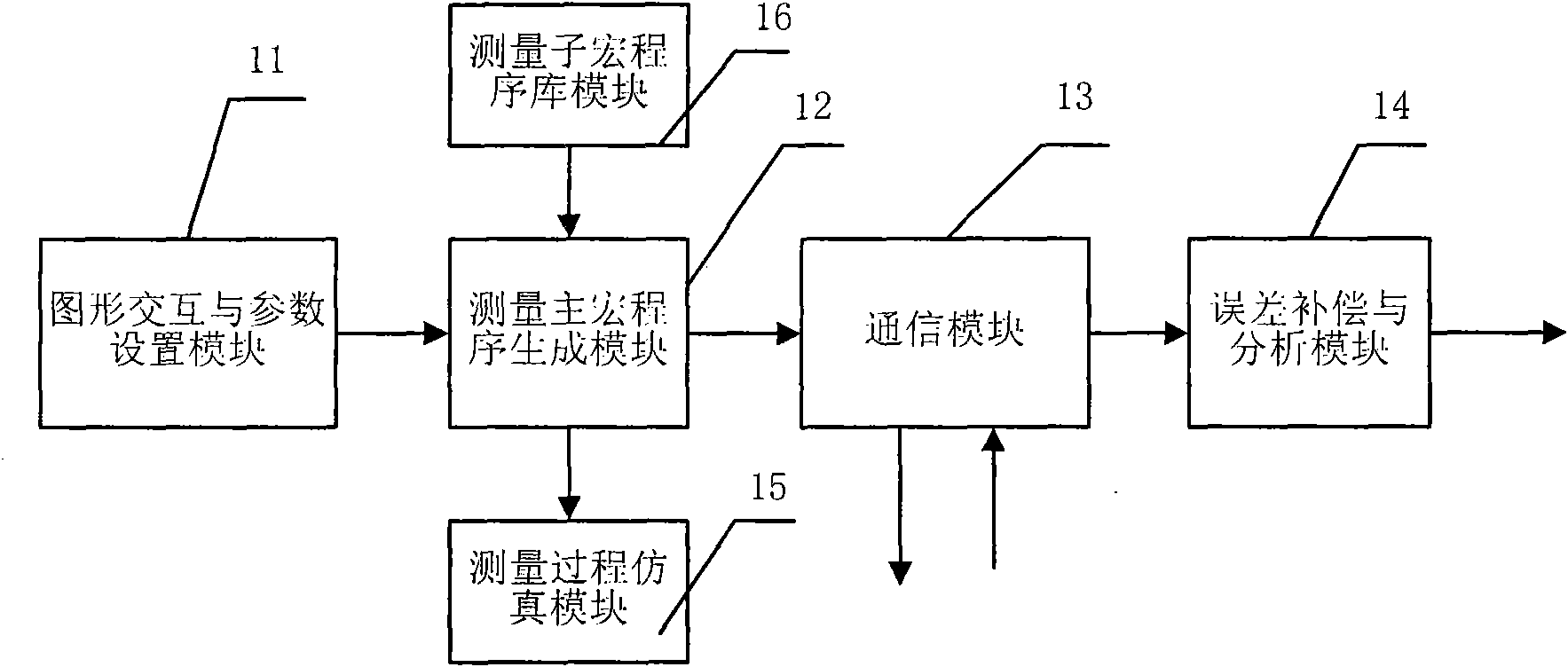

[0055] The virtual CNC machine tool online detector 6 obtains the graphic information of the workpiece to be tested from the computer 1, and provides a human-computer interaction interface. The parameters automatically generate the measurement master macro program, and the measurement master macro program is uploaded to the numerical control system through the computer 1; at the same time, the virtual numerical control machine tool online detector 6 receives the detection data output by the numerical control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com