3Cr seamless steel pipe and production method thereof

A technology of seamless steel pipes and steel pipes, applied in the field of metallurgy, can solve the problems of unsatisfactory mechanical properties and high cost of 3Cr seamless steel pipes, and achieve the effects of high cost, excellent performance and fast cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

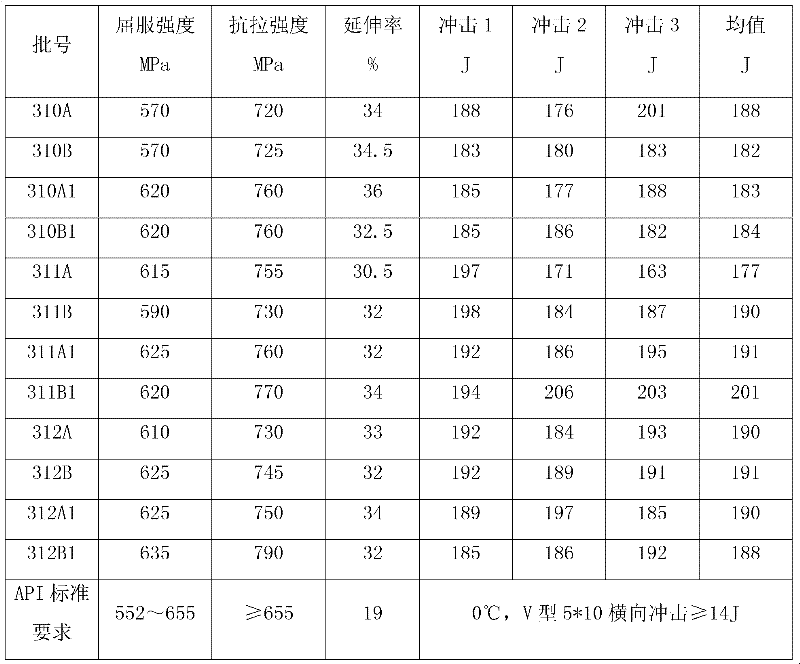

[0017] According to the API 5CT standard L-80 steel grade, the 3Cr seamless steel pipe with the specification of 244.48*11.05 is produced. The steel grade is 20Cr3Mo. The specific composition is shown in Table 1.

[0018] Table 1 Chemical composition of 20Cr3Mo steel

[0019] C

Si

mn

P

S

Cr

Mo

Al

Ti

0.15

0.22

0.65

0.016

0.004

3.03

0.39

0.025

0.01

[0020] Production process flow: electric furnace steelmaking → continuous casting of 280 billets → hot rolling of 340 continuous rolling mills → quenching and tempering heat treatment → flaw detection, hydraulic pressure, inspection, packaging.

[0021] 1. Electric furnace steelmaking:

[0022] ●Raw material requirements

[0023] Hot metal: P≤0.090%, S≤0.050%, As≤0.02%, Sn≤0.01%;

[0024] Steel scrap: pipe head, billet head, billet tail or a class of scrap steel with low five harmful elements and residual elements; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com