Durability test method and device of swing mechanism

A technology of durability test and slewing mechanism, which is applied in machine gear/transmission mechanism testing, liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve problems such as no slewing mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

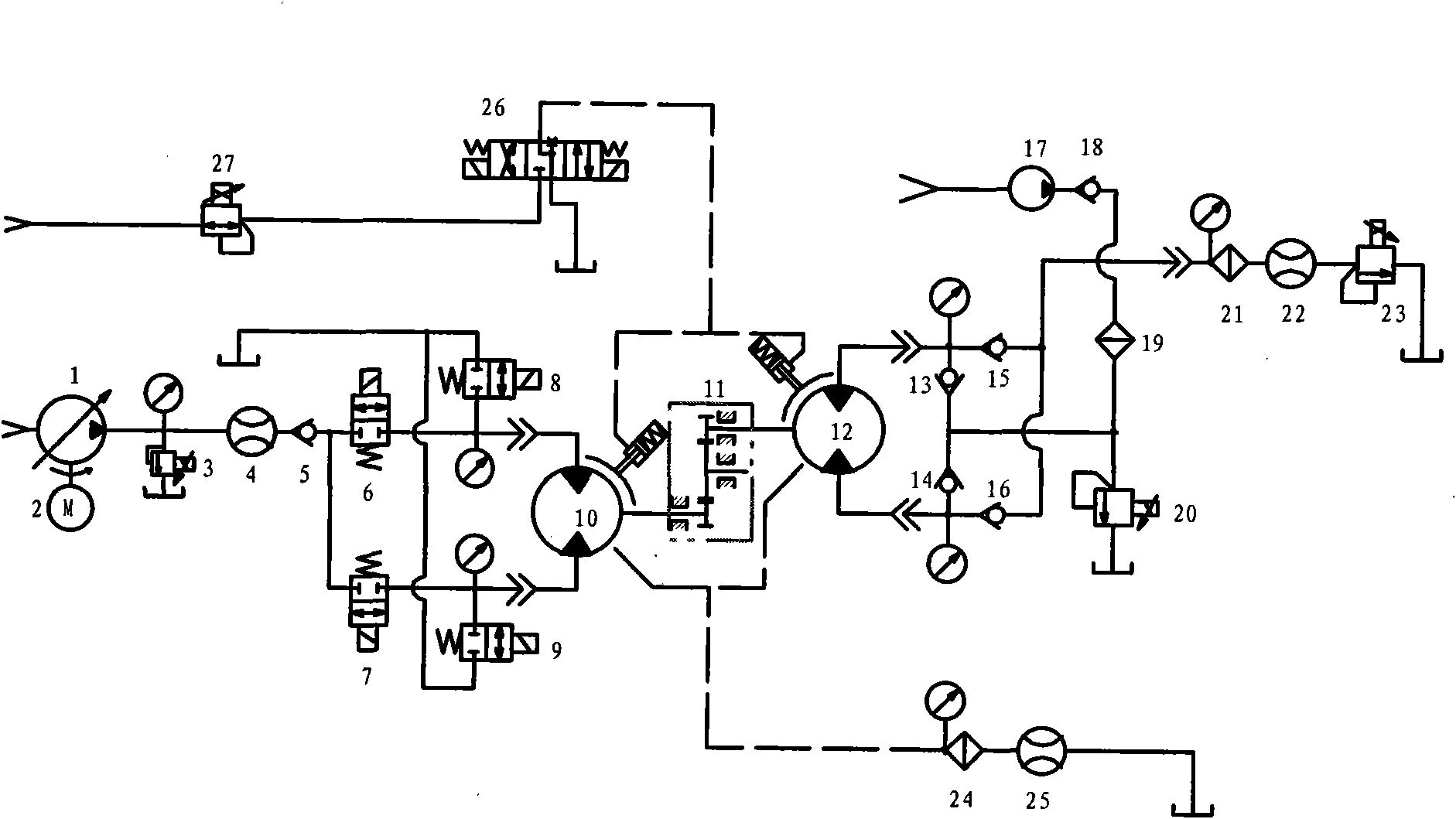

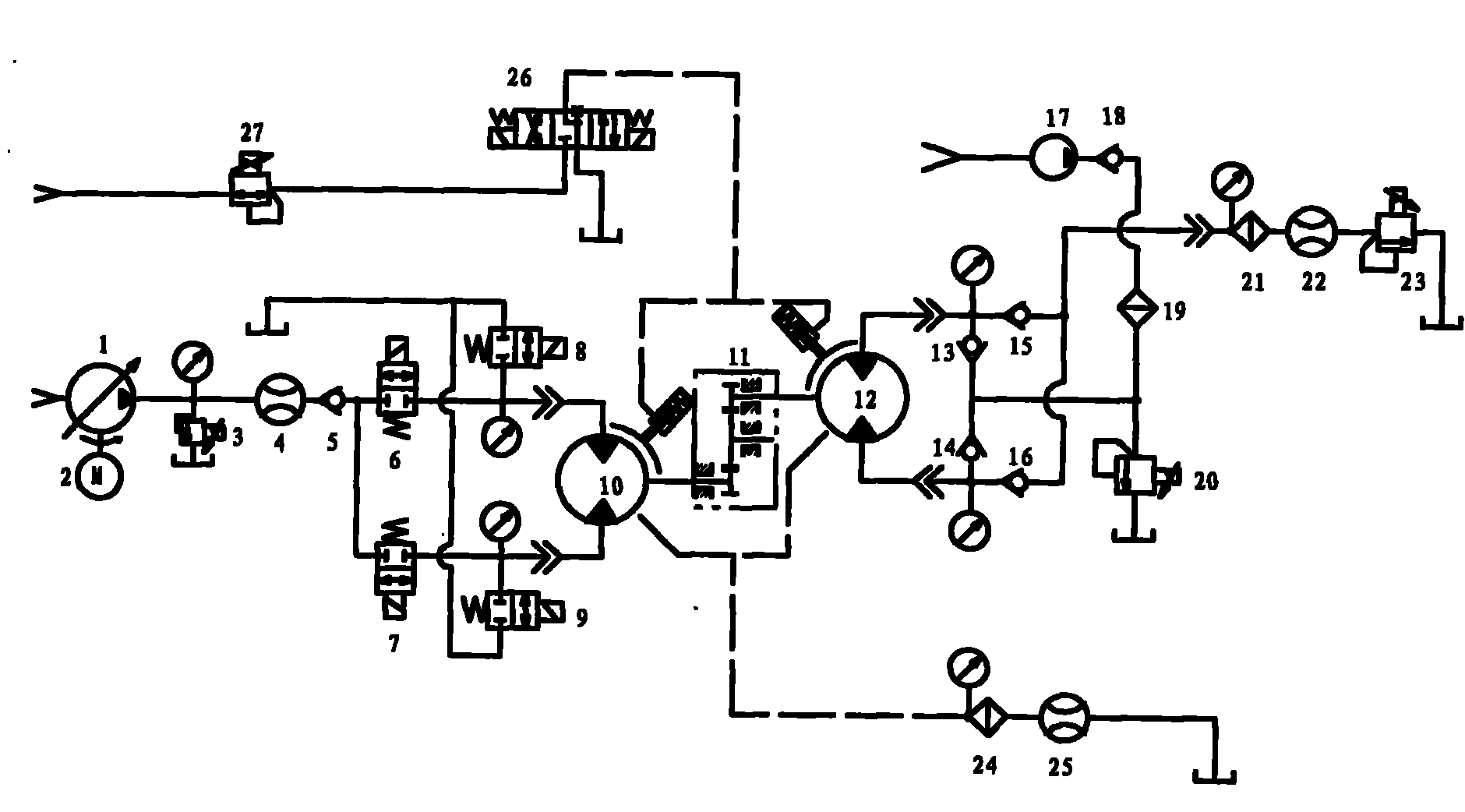

[0028] Embodiment 1: The durability test device includes a power hydraulic system circuit, a loading hydraulic system circuit, a brake hydraulic system circuit and a leakage test circuit, the power hydraulic system circuit controls the active slewing mechanism; the passive slewing mechanism is connected to the loading hydraulic system circuit; The circuit of the dynamic hydraulic system controls the opening and closing of the brakes of the active slewing mechanism and the passive slewing structure; the leakage test circuit tests the leakage of the motors of the active slewing mechanism and the passive slewing mechanism.

[0029] The power hydraulic system circuit includes: hydraulic pump 1, motor 2, safety valve 3, first flow sensor 4, first check valve 5, first electromagnetic reversing valve 6, second electromagnetic reversing valve 7, first The three electromagnetic reversing valves 8, the fourth electromagnetic reversing valve 9 and the active rotary motor 10, the output sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com