Trailer hydraulic road core machine

A technology for coring machines and trailers, which is applied in the direction of sampling devices, mechanical equipment, fluid pressure actuators, etc. It can solve the problems of laborious adjustment of fixed supports, heavy coring machine equipment, and large gasoline engine swings, etc., and achieves simple and convenient operation. The effect of lowering the center of gravity of the vehicle and uniform weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

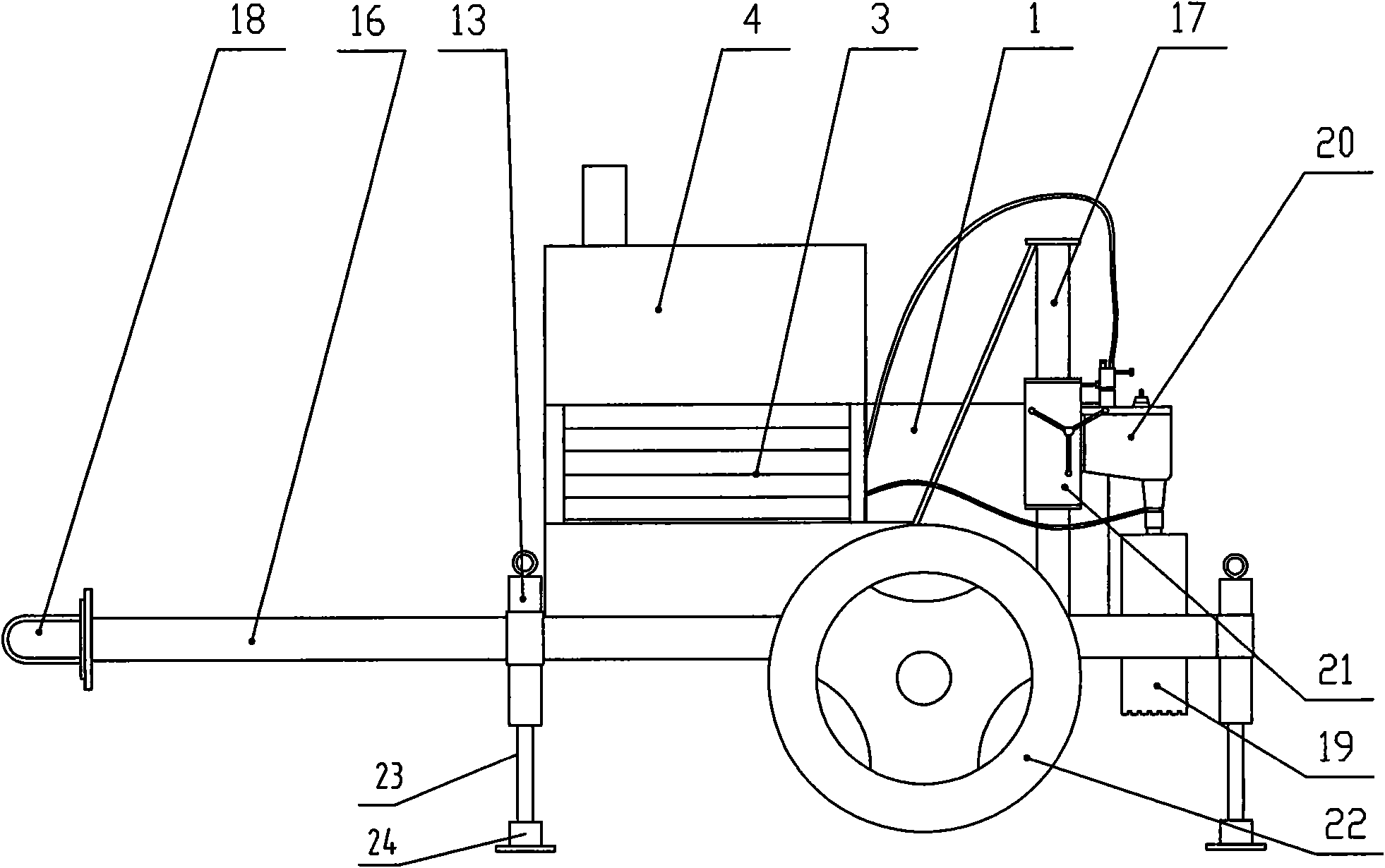

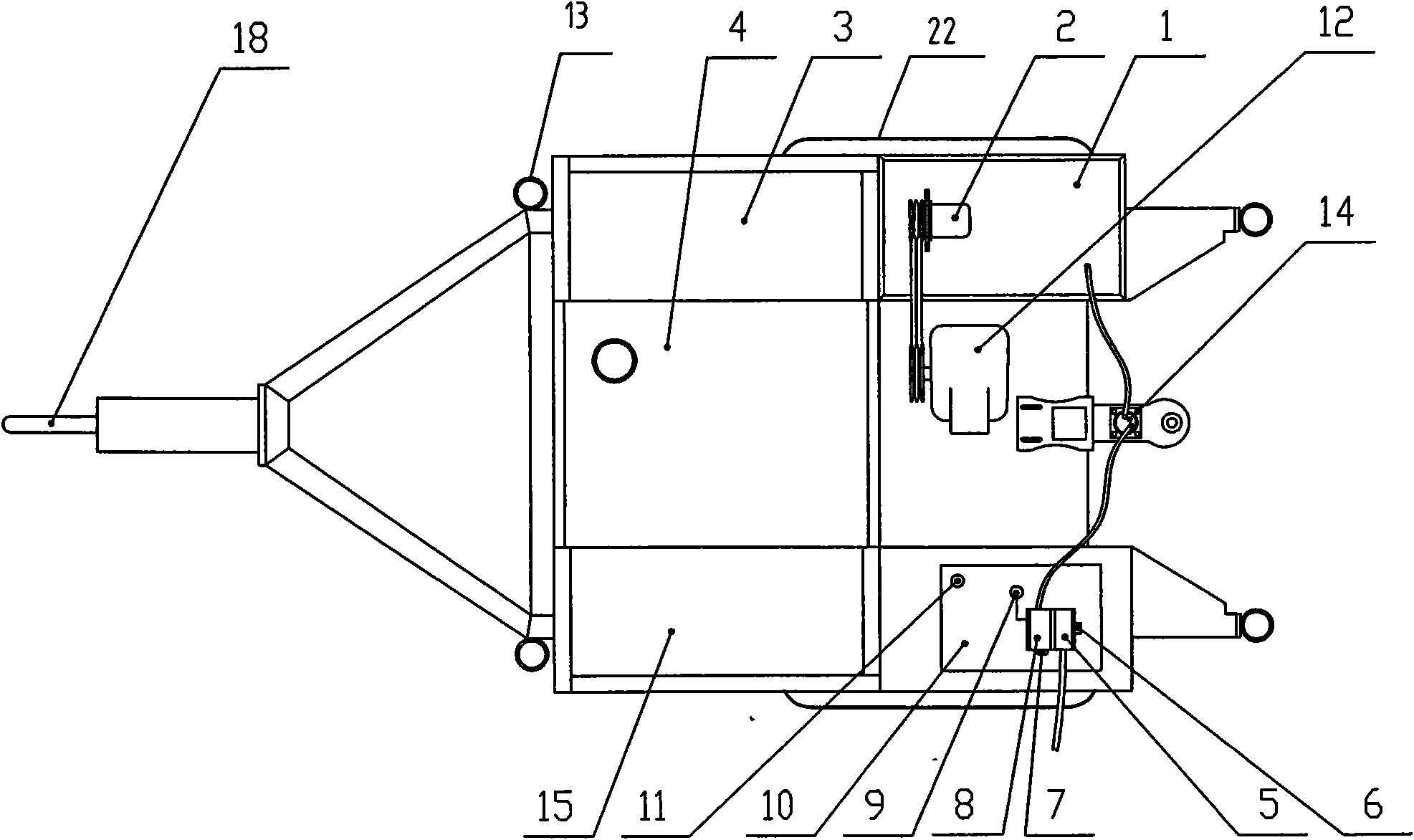

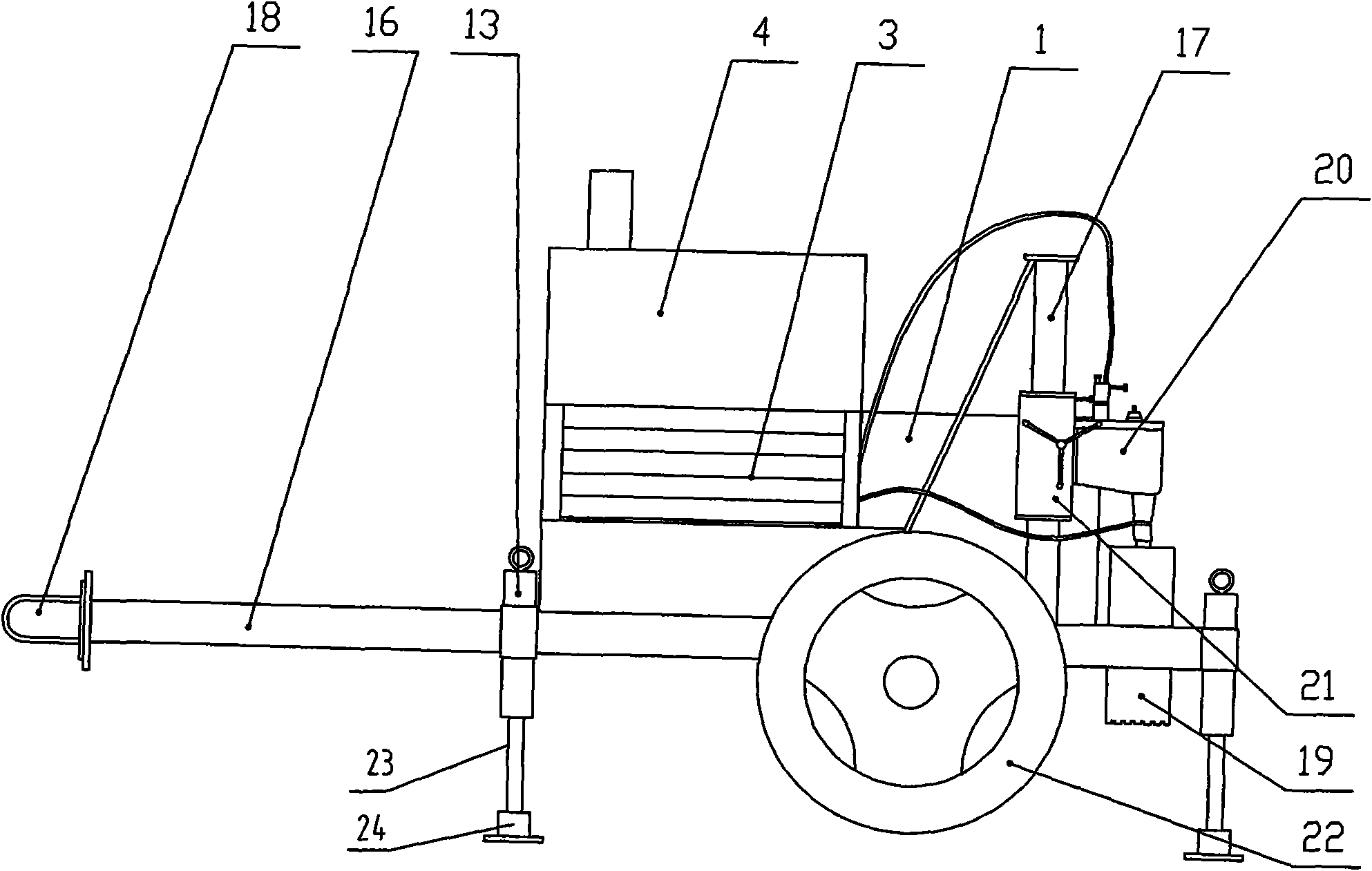

[0011] Such as figure 1 and figure 2 As shown, the trailer-type hydraulic road surface coring machine is composed of a car body 16, a gasoline engine 12, a coring machine, a tool box 3, a tool box 15, a water tank 4, four fixed supports 24, wheels 22 and a hydraulic workstation. Provided with a trailer traction 18, the coring machine includes a hydraulic motor 14, a reducer 20, a coring drill 19 and a lifting device. The lifting device is composed of a rack 17 and a sliding seat 21. The rack 17 is fixed on the car body 16 and slides. The gear that rack 17 engages is arranged on seat 21, and speed reducer 20 is fixed on the slide seat 21, and the height of adjustment slide seat 21 can drive speed reducer, hydraulic motor and coring drill bit to move up and down. The hydraulic workstation includes oil tank 1, gear oil pump 2, four hydraulic cylinders 13, manual reversing valve 5, overflow valve 6, one-way valve 7, manual reversing valve 8, pressure gauge 9, manifold 10, and ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com