Micron-sized metal powder metallic phase mounting method

A metal powder and metallographic sample mounting technology, applied in the preparation of test samples, etc., to achieve the effect of low equipment requirements, high practical application value, and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

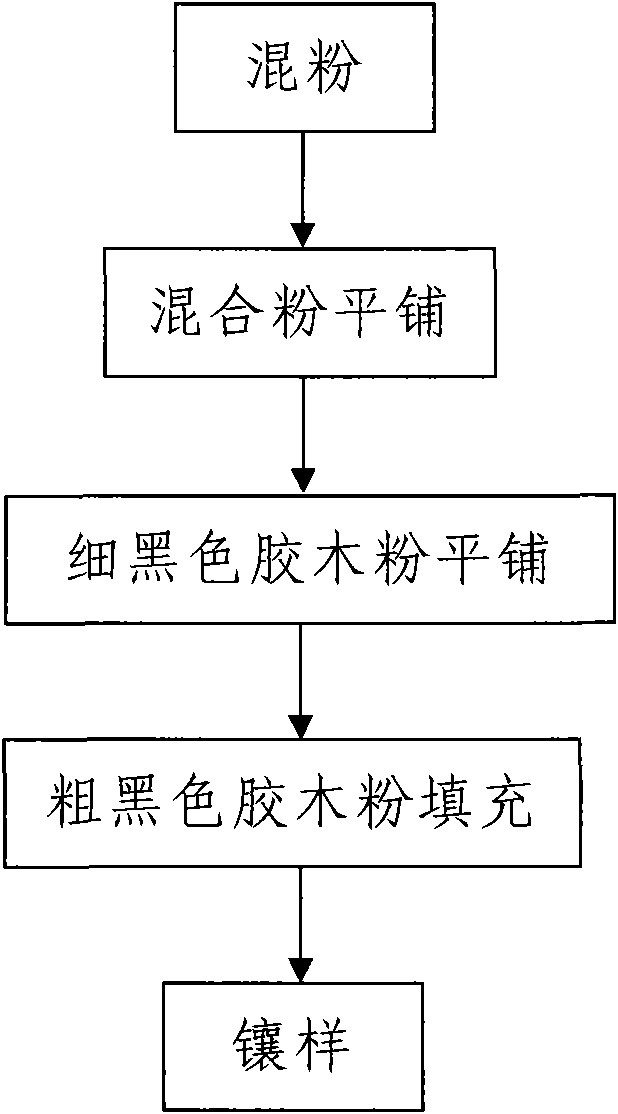

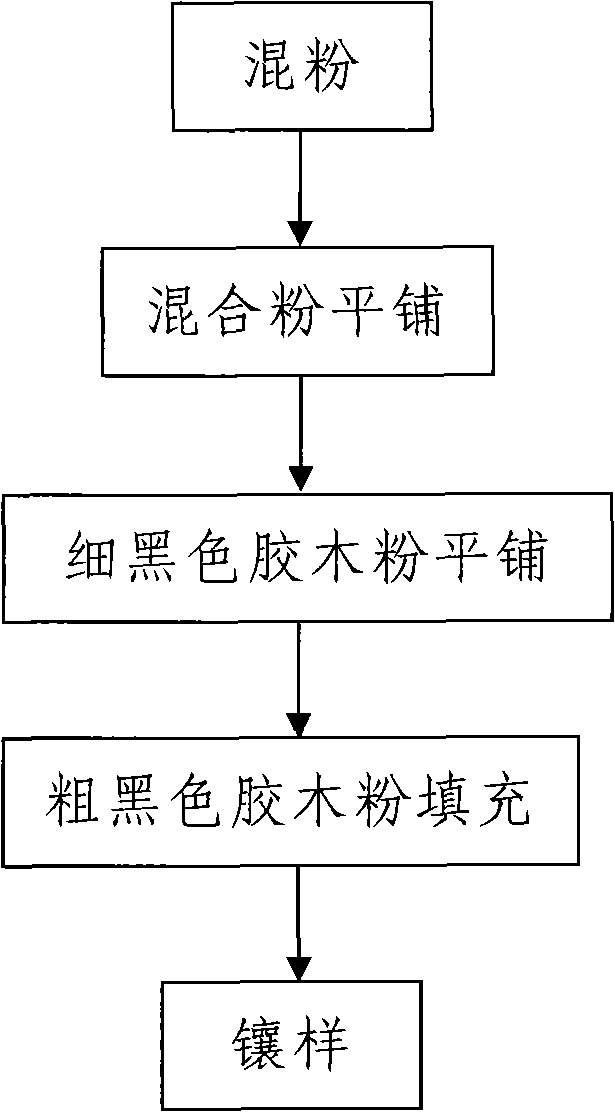

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the micron-scale metal powder to be inlaid is TaWHf powder with an average particle size of 200 μm, and when the TaWHf powder is metallographically mounted, the process is as follows: first, in a container, mix the TaWHf powder with fine black bakelite Mix the powder according to the volume ratio of 1:1 to obtain the mixed powder. The fine black bakelite powder used is black bakelite powder with a particle size of 60 μm to 100 μm; In the machine cavity and the layer thickness of the mixed powder layer is 6mm, and then spread a layer of fine black bakelite powder with a thickness of 6mm on the already laid mixed powder layer, and the fine black bakelite powder used has a particle size of 60μm~ 100 μm black bakelite powder, and then fill the coarse black bakelite powder on the fine black bakelite powder layer that has been laid until the machine cavity of the hot mounting machine is filled and the coarse black bakelite powder used has a particle size of...

Embodiment 2

[0039]In this embodiment, the micron-scale metal powder to be inlaid is TaW12 powder with an average particle size of 170 μm, and when the TaWHf powder is metallographically mounted, the process is as follows: first, in a container, mix the TaWHf powder with fine black bakelite The powder is mixed according to the volume ratio of 1:1 to obtain the mixed powder. The fine black bakelite powder used is black bakelite powder with a particle size of 50 μm to 80 μm; In the machine cavity and the layer thickness of the mixed powder layer is 5mm, and then spread a layer of fine black bakelite powder with a thickness of 5mm on the already laid mixed powder layer, and the fine black bakelite powder used has a particle size of 50μm~ 80 μm black bakelite powder, and then fill the coarse black bakelite powder on the fine black bakelite powder layer that has been laid until the machine cavity of the hot mosaic machine is filled and the coarse black bakelite powder used has a particle size of...

Embodiment 3

[0042] In this embodiment, the micron-sized metal powder to be inlaid is Ti powder with an average particle diameter of 25 μm, and when the Ti powder is metallographically mounted, the process is as follows: first, put the Ti powder and fine black Bakelite in a container The powder is mixed according to the volume ratio of 1:2 to obtain the mixed powder. The fine black bakelite powder used is black bakelite powder with a particle size of 30 μm to 60 μm; In the machine cavity and the layer thickness of the mixed powder layer is 3mm, and then spread a layer of fine black bakelite powder with a thickness of 1mm on the laid mixed powder layer and the particle size of the fine black bakelite powder used is 30μm~ 60 μm black bakelite powder, and then fill the coarse black bakelite powder on the fine black bakelite powder layer that has been laid until the machine cavity of the hot mosaic machine is filled and the coarse black bakelite powder used has a particle size of 400 μm~1mm Bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com