Surface positioning device and method based on linear image sensors

A linear image and positioning method technology, applied in the input/output process of instruments, data processing, electrical digital data processing, etc., can solve the problems of complex control timing, high cost, and many parameters, so as to avoid sampling and calculation, installation The effect of low space requirement and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

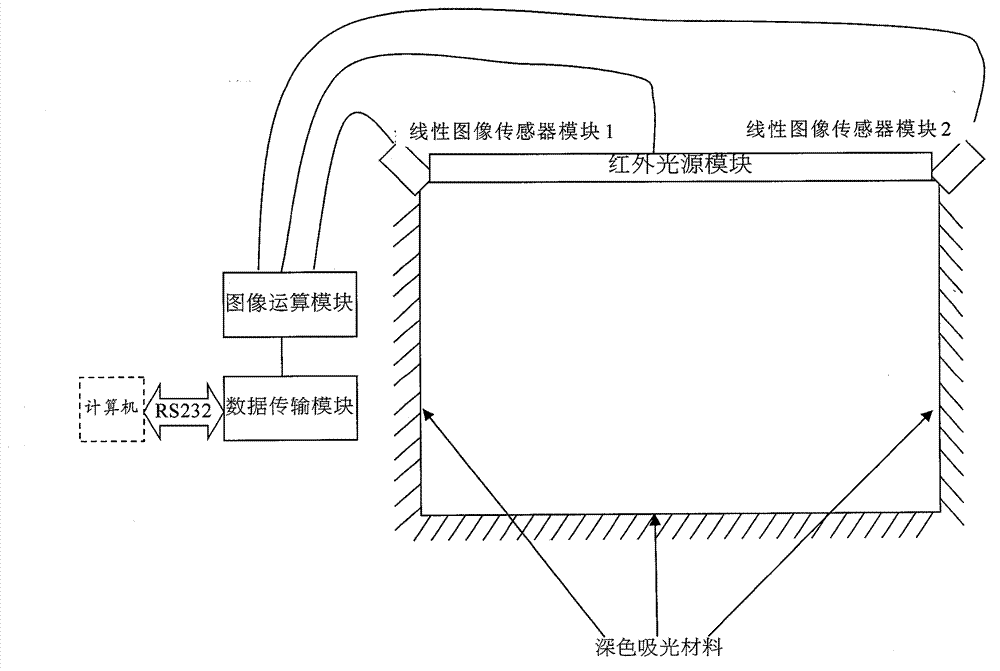

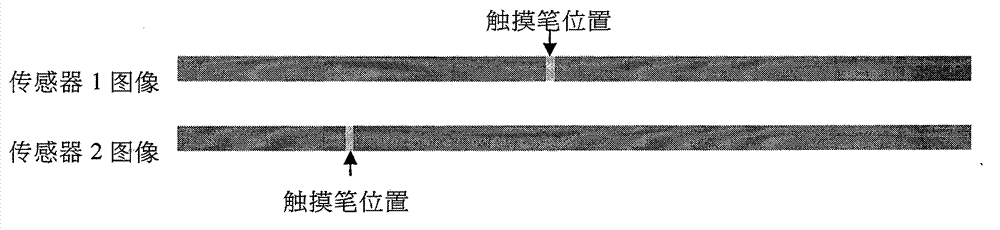

[0030] Such as figure 1 As shown, it is a schematic structural diagram of the surface positioning device based on the linear image sensor of the present invention.

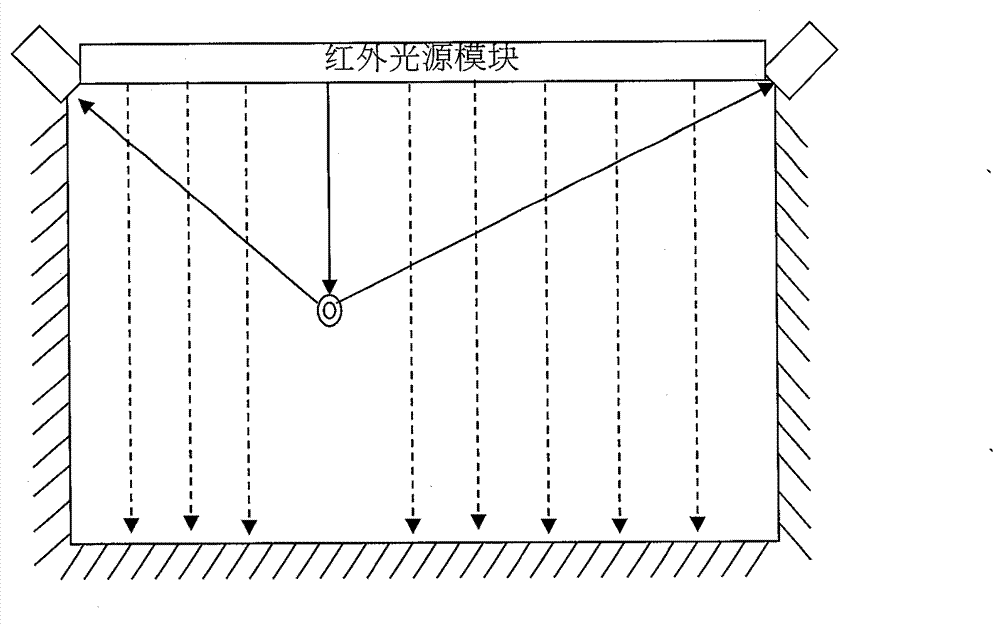

[0031] The two linear image sensors are respectively installed in the upper left corner and the upper right corner of the positioning surface. The linear image sensor 1 in the upper left corner is installed obliquely to the lower right at 45°, and the linear image sensor 2 in the upper right corner is installed obliquely to the lower left at 45°, so that the two The imaging surface of the linear image sensor can capture the entire positioning surface. The left surface, the right surface, and the lower surface of the positioning surface are pasted with dark light-absorbing materials to prevent infrared light from being reflected when there is no touch event.

[0032] When no touch event occurs on the positioning surface, the infrared light emitted by the infrared light source is absorbed by the dark light-absorbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com