Discharging pulley for insulator injection molding machine

A technology for injection molding machines and insulators, applied in insulators, electrical components, circuits, etc., can solve the problems of low efficiency, potential safety hazards, and high labor intensity of workers, and achieve the effect of high efficiency and avoiding potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

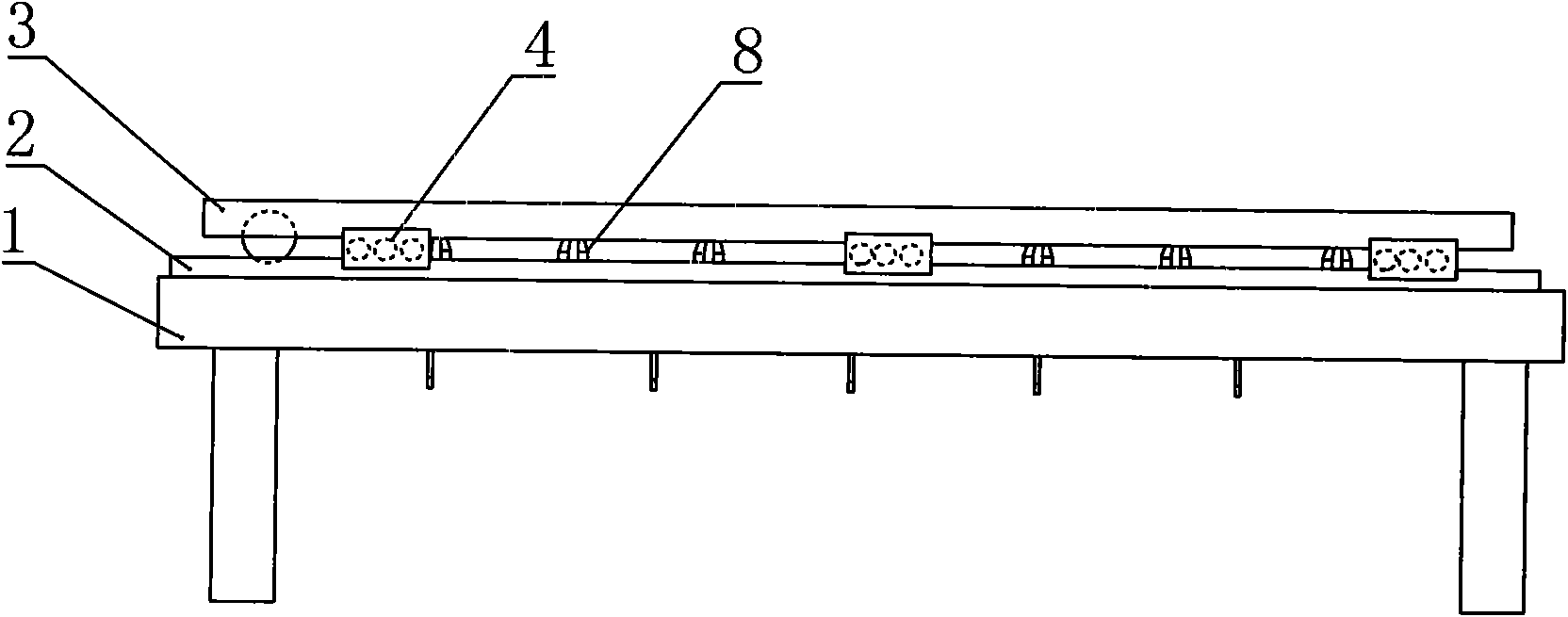

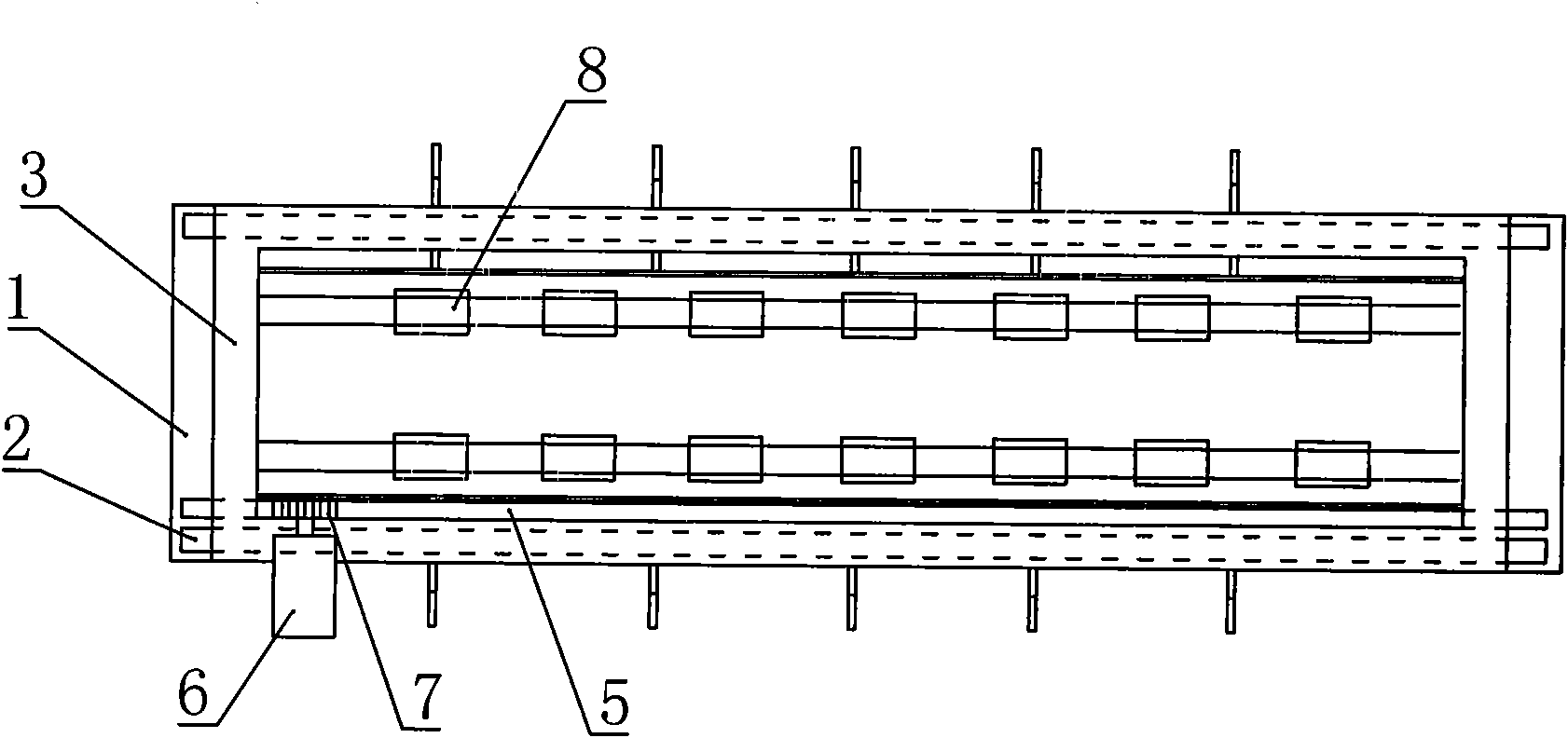

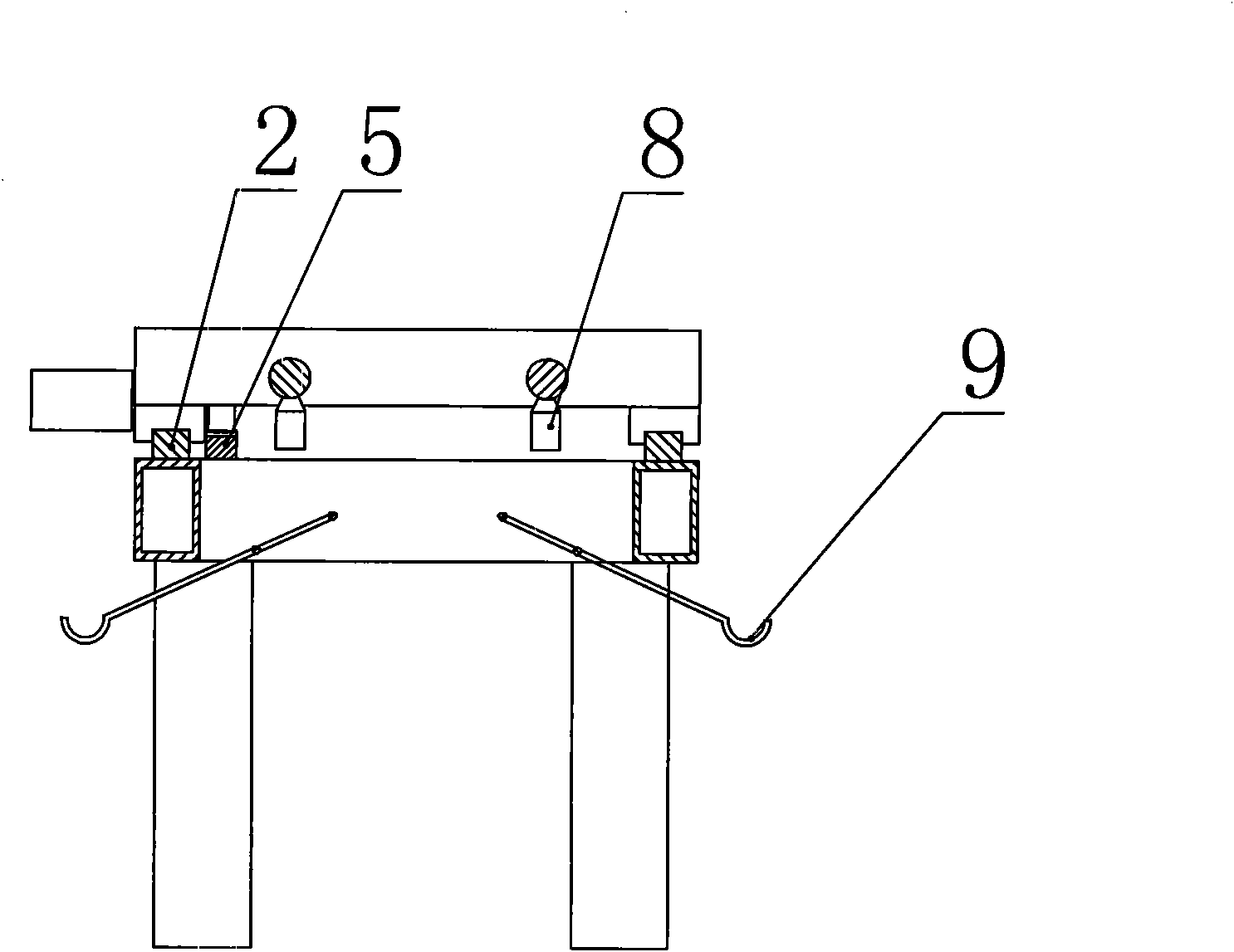

[0012] like figure 1 , 2 , Shown in 3, including frame 1, guide rail 2, movable frame 3, slide block 4, rack 5, drive motor 6, gear 7, mechanical clamp 8, guide frame 9.

[0013] The frame 1 is provided with a horizontal guide rail 2 , and the inside of the guide rail 2 is provided with a rack 5 extending along the guide rail 2 .

[0014] Movable frame 3 is located at guide rail 2 tops, and its bottom is equipped with the slide block 4 that falls on guide rail 2, and the lower end face of this slide block 4 is made the groove type of indentation, is provided with roller in the groove type. A drive motor 6 is installed inside the movable frame 3 , and a gear 7 meshed with the rack 5 is fixed at the end of the drive motor 6 . At least one set of mechanical clamps 8 for clamping the shed of the insulator is provided in the movable frame 3, and the mechanical clamps 8 are opened and closed by the cylinder drive, and the cylinders of the mechanical clamps 8 and the drive motor 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com