Integral manual production device for 12V20AH lead acid battery electrode group soldering and discharging

A 1.12V20AH, lead-acid battery technology, applied in the direction of battery components, circuits, electrical components, etc., can solve the problems of inability to ensure the same compactness of the pole group, large one-time investment, heavy weight, etc., to save manpower Resources and time, guaranteed quality, light weight results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

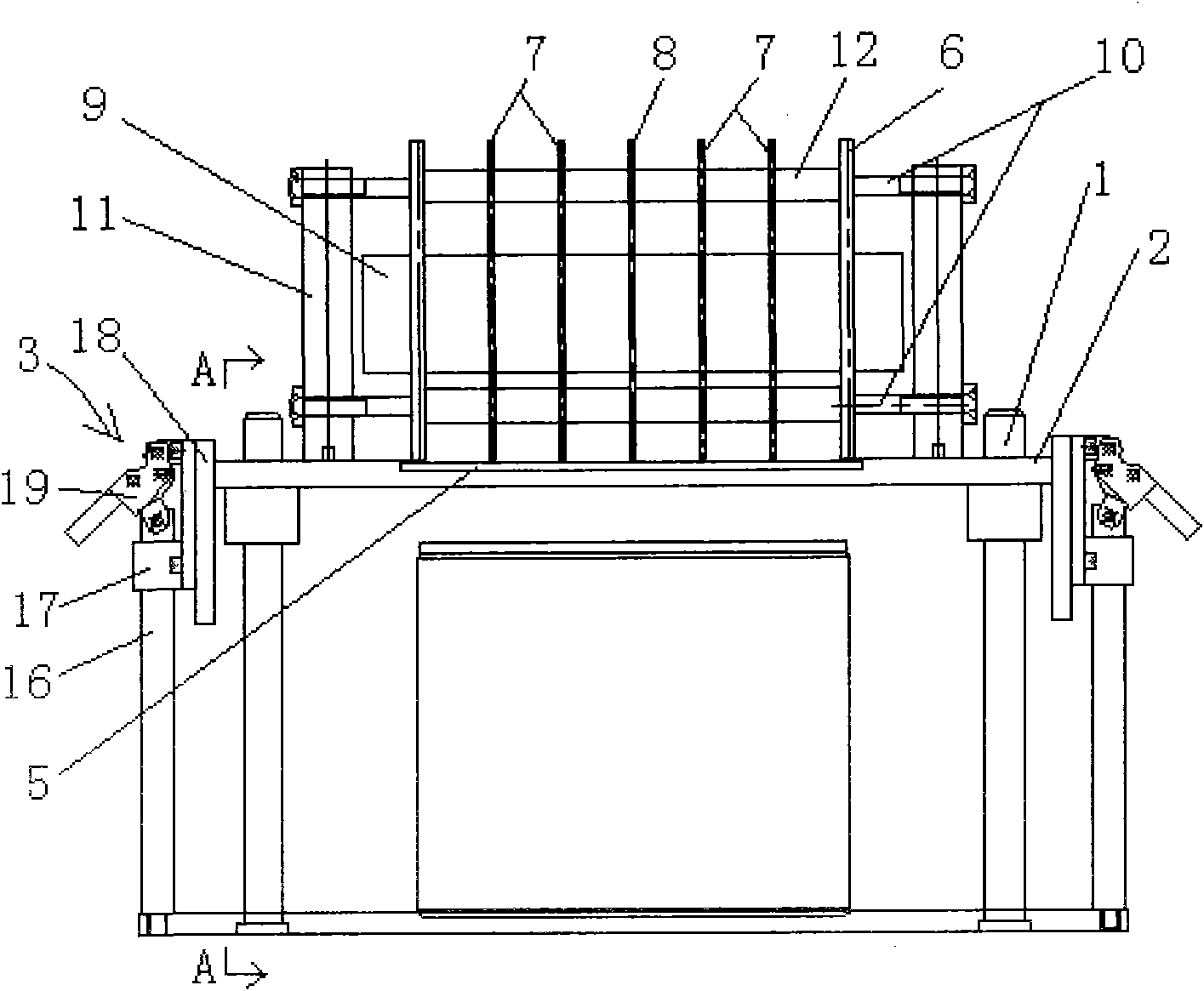

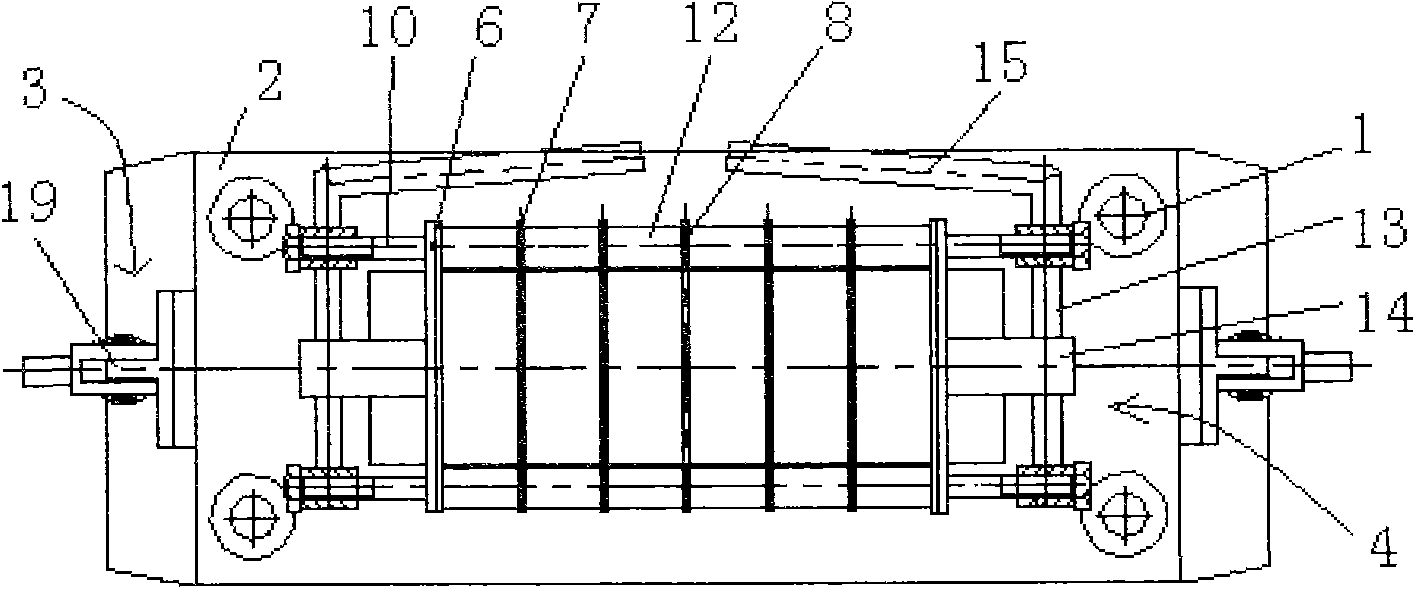

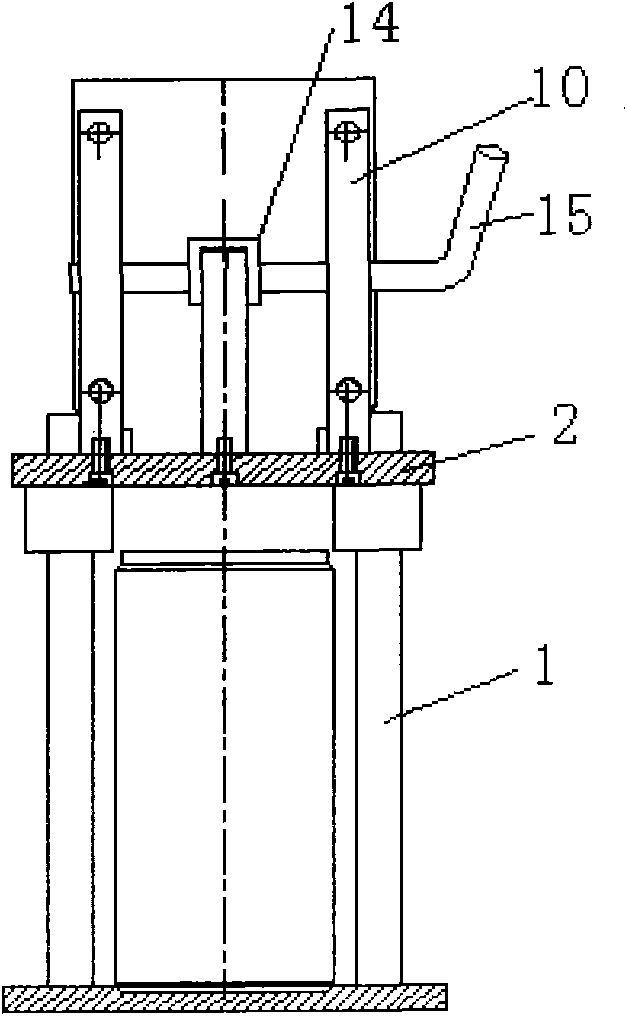

[0018] Such as figure 1 , 2 As shown in , 3, the 12V20AH lead-acid battery electrode group welding and lower tank integrated manual production device includes a workbench 2 that is movably connected to the guide post 1 of the frame (the lower surface of the workbench 2 is provided with a guide sleeve to cooperate with the guide post 1 play a stable guiding role), the lifting device 3 for the workbench 2 to move up and down, and also include the welding group box arranged on the workbench 2, the partition in the welding group box (the length direction of the welding group box is divided into six cavities, The six cavities are respectively corresponding to the inner cavity of the battery case under the workbench), and the pressing device 4 that squeezes the pole group in the welding group box, and also includes a plug that blocks the welding group box and the notch under the workbench. plate 5. The end plate 6 of the welding group box, and the two sides of the first, second, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com