Improvements in or relating to shredder cutters

A technology of shredders and knives, applied in the direction of cutting tools, agricultural machinery and implements, cutting equipment, etc., can solve problems such as complexity, fiber damage, and poor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

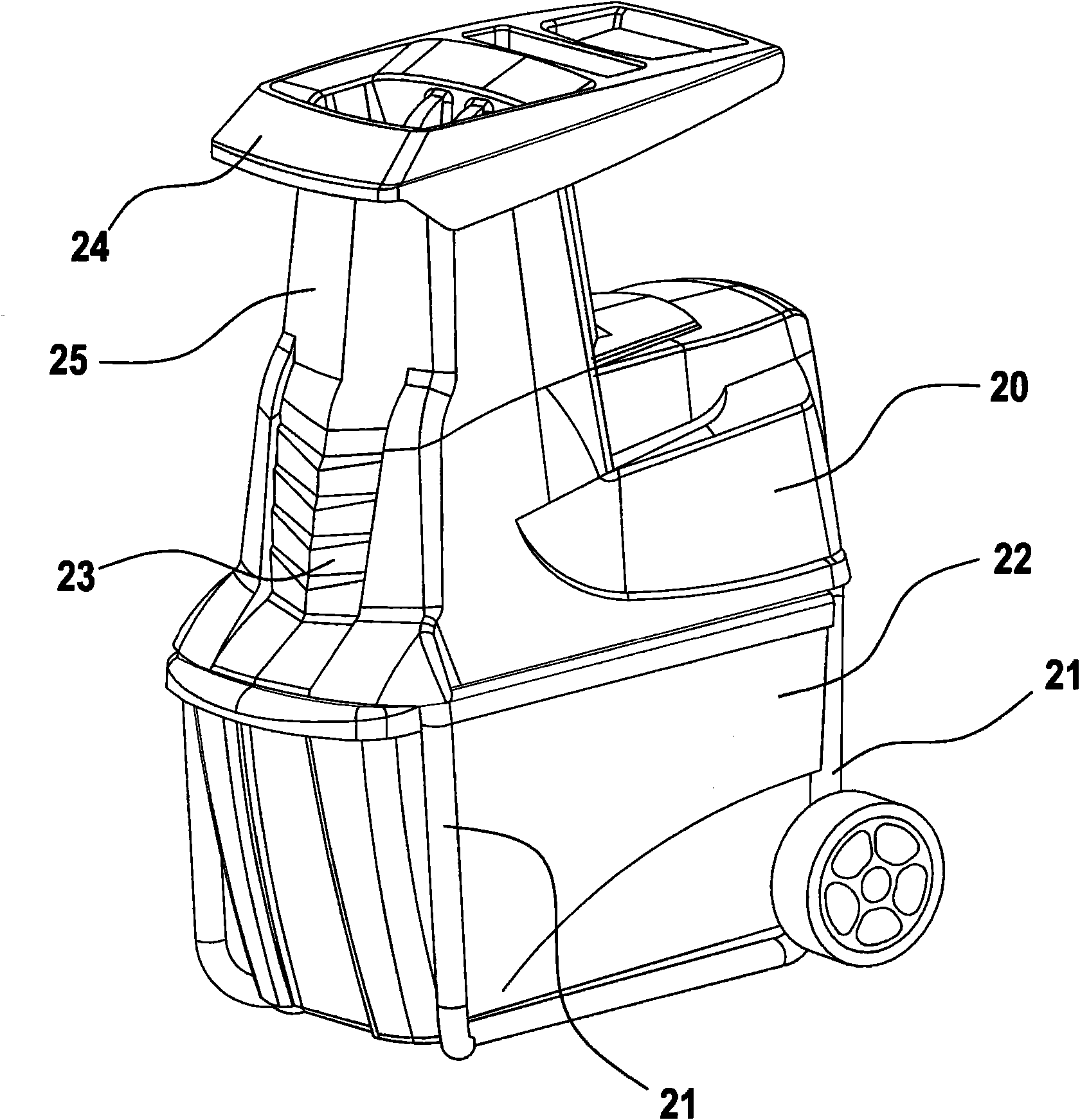

[0032] figure 2 Shown is a shredder body 20 comprising a shredder knife assembly mounted on a frame 21 above a collection box 22 in operative communication with an outlet 23 of the shredder body 20 . The shredder body 20 has an inlet or funnel 24 for receiving vegetation to be chopped, such as branches or treetops. Feed port 24 is separated from the knife assembly by feed slot 25 to prevent user access to the knife assembly during use.

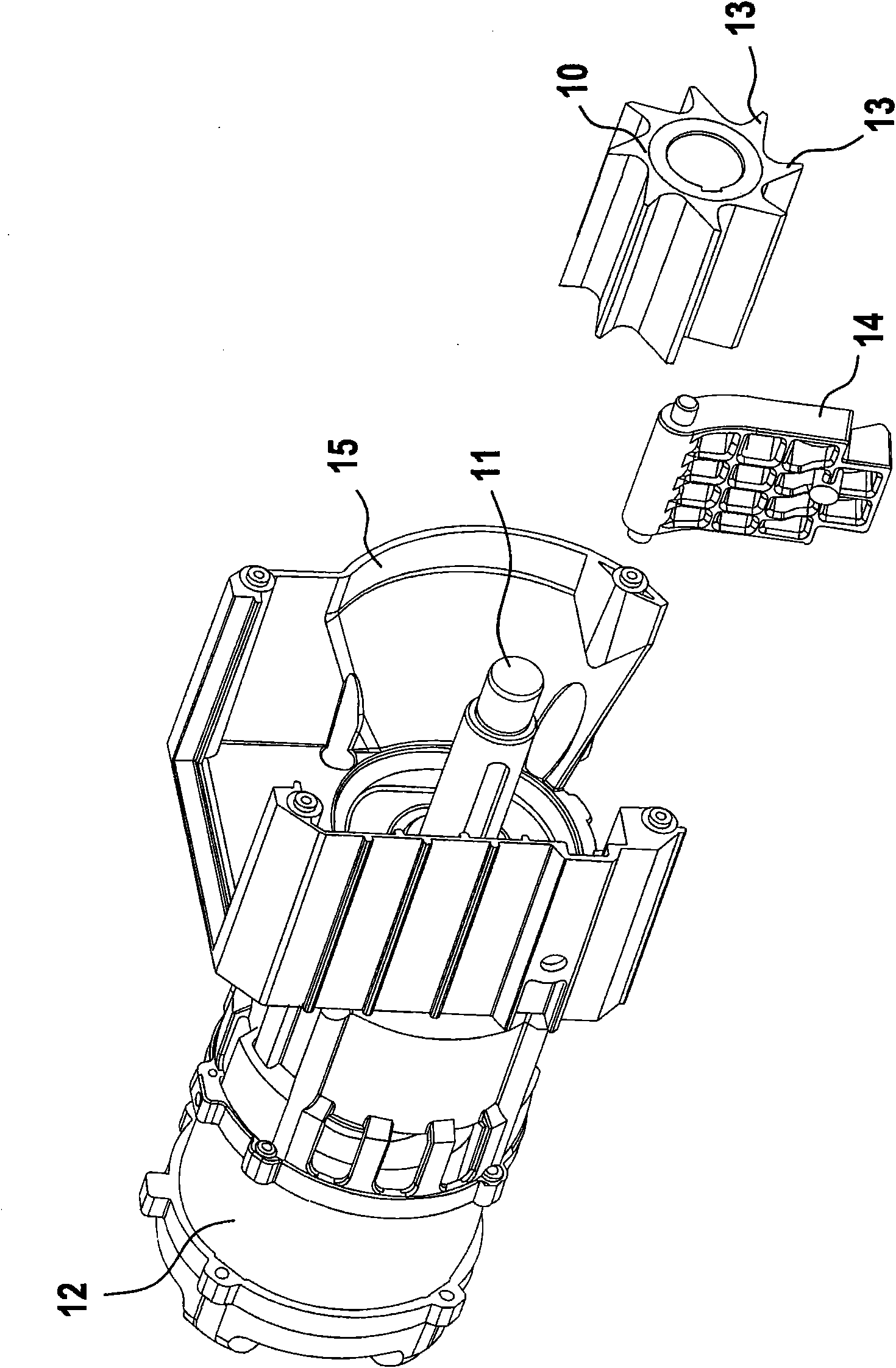

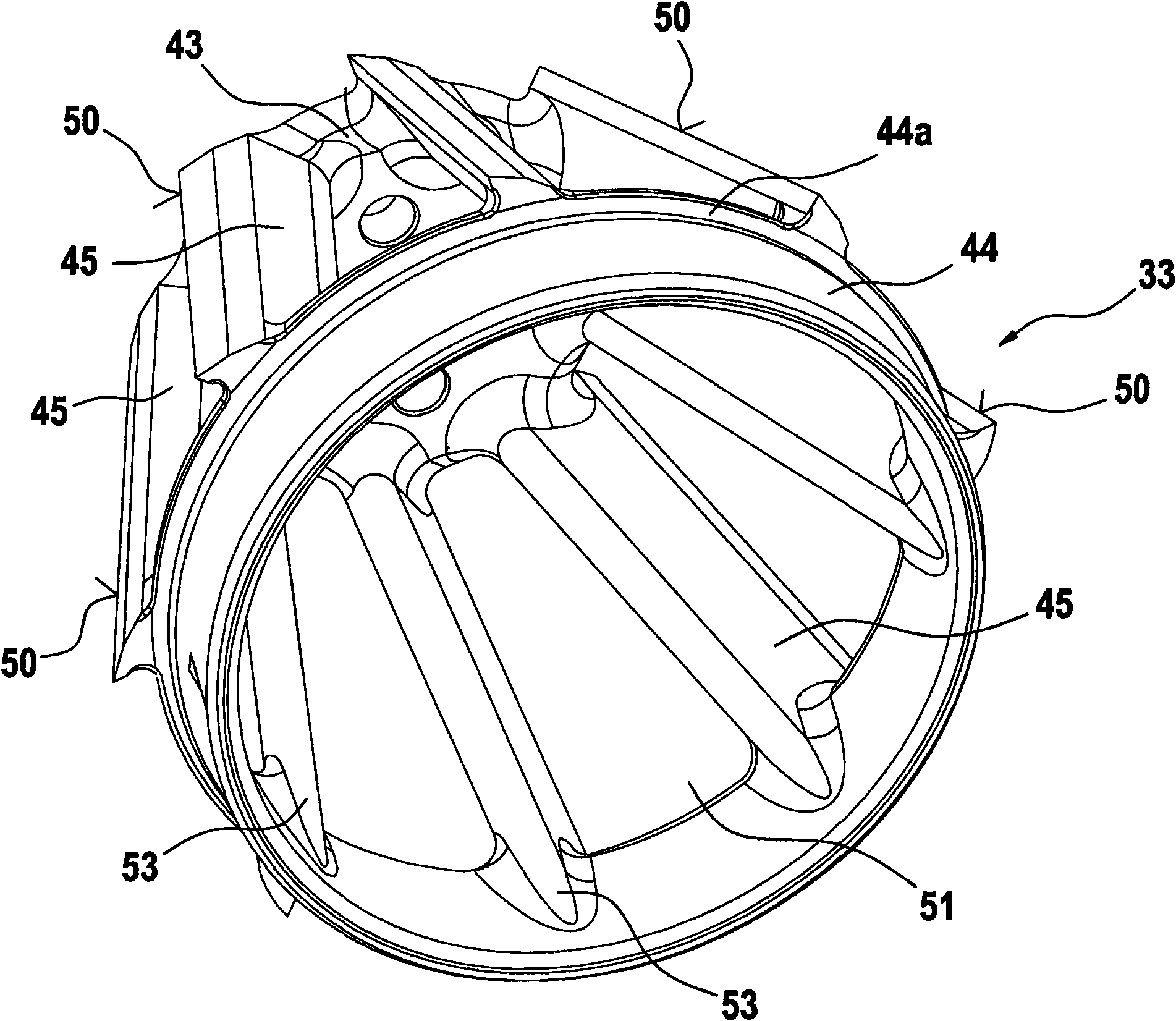

[0033] refer to Figure 5 , shows a cutter assembly of a shredder comprising a motor and gearbox unit 30 with a rotating shaft 31 carrying a torque transfer device 32 for transferring torque to the cutter. The cutting element 33 according to the invention is mounted on the conveyor device 32 . The knife assembly includes a housing 34 to house a cutting element 33 and define a shredding cavity. The housing includes an operative upper opening or inlet 35 for receiving vegetation to be chopped and an operative lower opening or outlet 36 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com