Preparing method of high-density and high-purity sputtering rotation silver target material

A high-purity, high-density technology, applied in sputtering coating, metal material coating process, ion implantation coating and other directions, can solve the problems of coarse grain structure, abnormal discharge, and many control parameters. The effect of uniform and fine structure, lower production cost and high deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Preparation of high relative density and high purity rotating silver target for sputtering

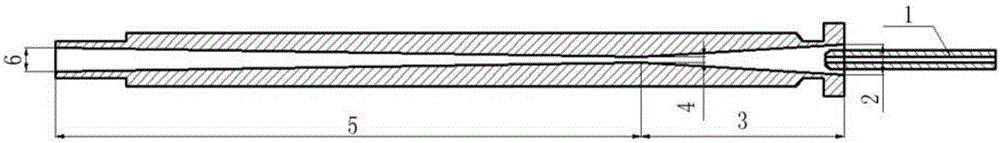

[0044] combine figure 1 Structural diagram of the Laval nozzle.

[0045] 1) Preparation of stainless steel back tube:

[0046] Cutting: use a sawing machine to saw a 304 stainless steel pipe of a specified length, the inner diameter of the steel pipe is 125mm, and the outer diameter is 133mm;

[0047] Car pipe: Carve out grooves, bevels, etc. at both ends of the stainless steel pipe according to the product drawings;

[0048] Surface roughening by sand blasting: the surface of the stainless steel pipe is sand blasted by a sand blast machine; the sand blast material is brown corundum with a particle size of 80 mesh;

[0049] Primer: take out the roughened stainless steel tube, and spray a layer of CuAl material on its surface through an arc spraying machine, with a coating thickness of 0.5 mm, to obtain a prepared stainless steel back tube;

[0050] 2) Silver coa...

Embodiment 2

[0055] Embodiment 2: effect verification test

[0056] See embodiment 1 for implementation steps. The results under different cold spraying conditions (different nitrogen pressure and different nitrogen heating temperature) are shown in Table 1.

[0057] Table 1 Results table under different cold spraying conditions

[0058] temperature (°C) Air pressure (Mpa) deposition rate Relative density 400 3.5 90% 93% 400 4 92% 95% 450 3.5 94% 91% 450 4.5 95% 95.6% 500 3.5 97% 98% 500 4.5 97.2% 98%

[0059] Among them: Deposition rate calculation method: measure the weight A1 of the back tube before spraying, measure the weight A2 of the target after spraying, the actual spraying powder weight is A3, and the deposition rate is (A2-A1) / A3*100%.

[0060] Relative density calculation method: Take a small piece of the sprayed target sample, use the Archimedes density meter to measure the real density P1 of the sample, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com