Strip steel section shape detecting and identifying method

A cross-section shape and recognition method technology, applied in the field of steel rolling quality control, can solve the problems of excessive deviation between the fitting curve and the measured value, the inability to obtain the shape characteristics of the cross-section of the strip, and the inability to detect the transverse thickness distribution of the strip. The effect of improving the shape quality and flatness quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

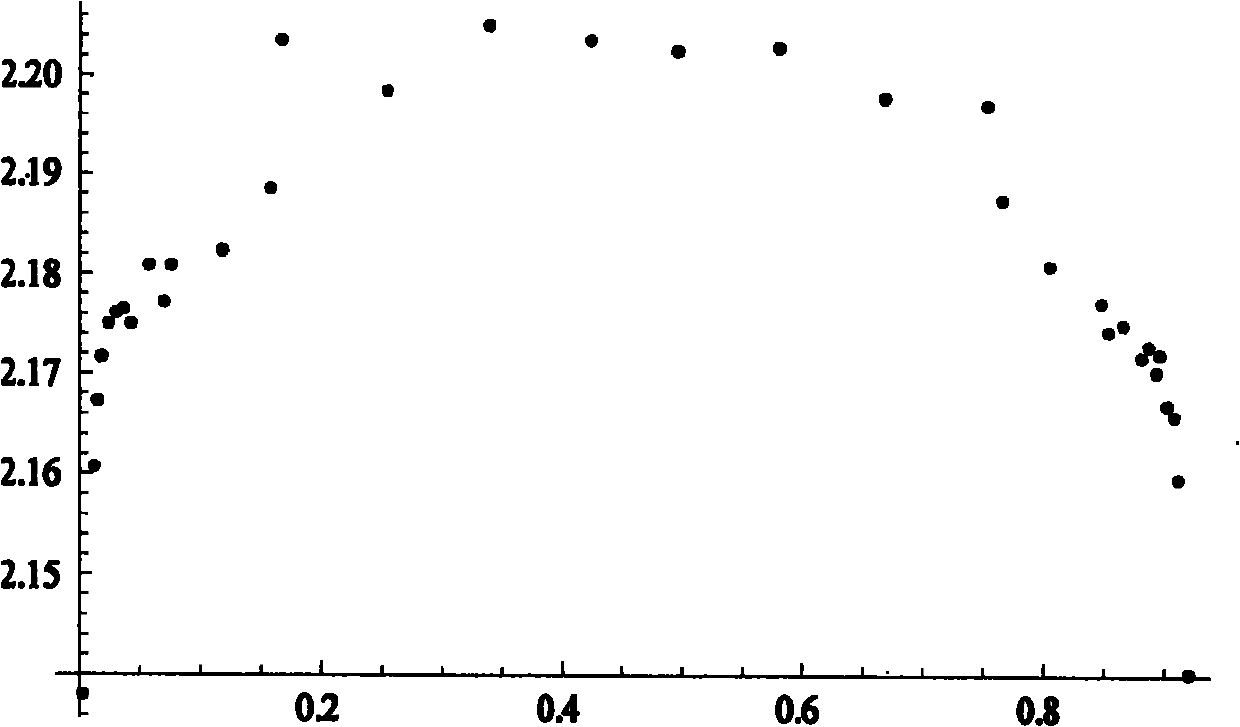

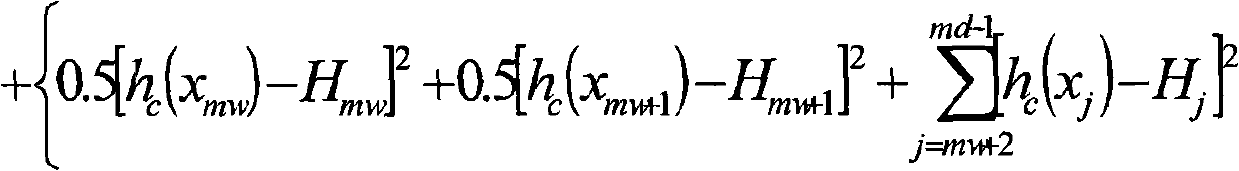

[0028] The detection and identification method of the strip steel section shape in this embodiment is based on the distribution characteristics of the strip steel transverse thickness, and the configuration of the measuring channel of the X-ray section detector follows the principles that can relatively comprehensively detect the strip steel section information and is also economical, such as image 3 and Figure 4 As shown, there are three groups in total, of which a set of edge detectors on the left and right sides can be moved in the width direction, which can automatically find the edge according to the width of the incoming strip, and a set of fixed detectors in the middle. The distribution density of the two groups of edge detection devices on the two sides is higher than that in the middle group, and the distribution of the measurement channels is gradually denser from the center to the two sides. Appropriately increase the number of measuring channels in the middle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com