Pneumatic slip shaft-based winding tension and rotation speed control method

A winding tension and speed control technology, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problems of no slip axis coordinated control, no dynamic compensation control of the dynamic process of speed up and down, and short life. , to achieve the effect of simple, easy and stable control compensation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific steps of the winding tension and speed control method based on the air-controlled slip shaft are as follows:

[0028] Step a calculates the winding radius R (unit: m) according to the strip thickness and winding length;

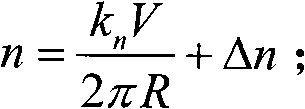

[0029] Step b calculates the speed n of the air-controlled slip shaft (unit: r / s);

[0030] Step c calculates the dynamic acceleration (decrease) speed of strip conveying (Unit: m / s 2 );

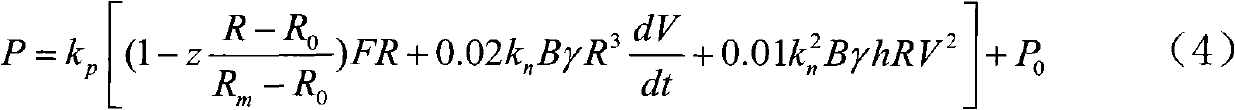

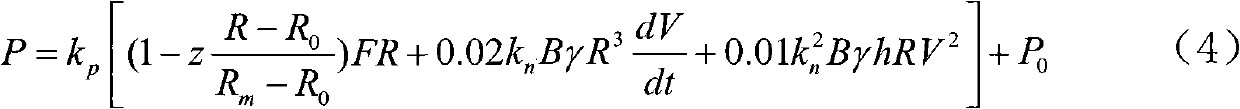

[0031] Step d calculates the input air pressure P (unit: MPa) of the air control slip shaft;

[0032] In step e, the obtained input air pressure P signal is input to the air-controlled slip shaft, and the speed n signal of the air-controlled slip shaft is input to the drive motor driver of the slip shaft, so as to realize the coordinated control of winding tension and speed.

[0033] The winding radius R described in the step a has a functional relationship R=r(h, L) with the strip thickness h (unit: m) and the winding length L (unit: m), which is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com