System capable of constructing in vertical structure and horizontal structure simultaneously in core tube

A technology of horizontal structure and core tube, which is applied in the direction of housing structure support, housing structure support, scaffolding supported by housing structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

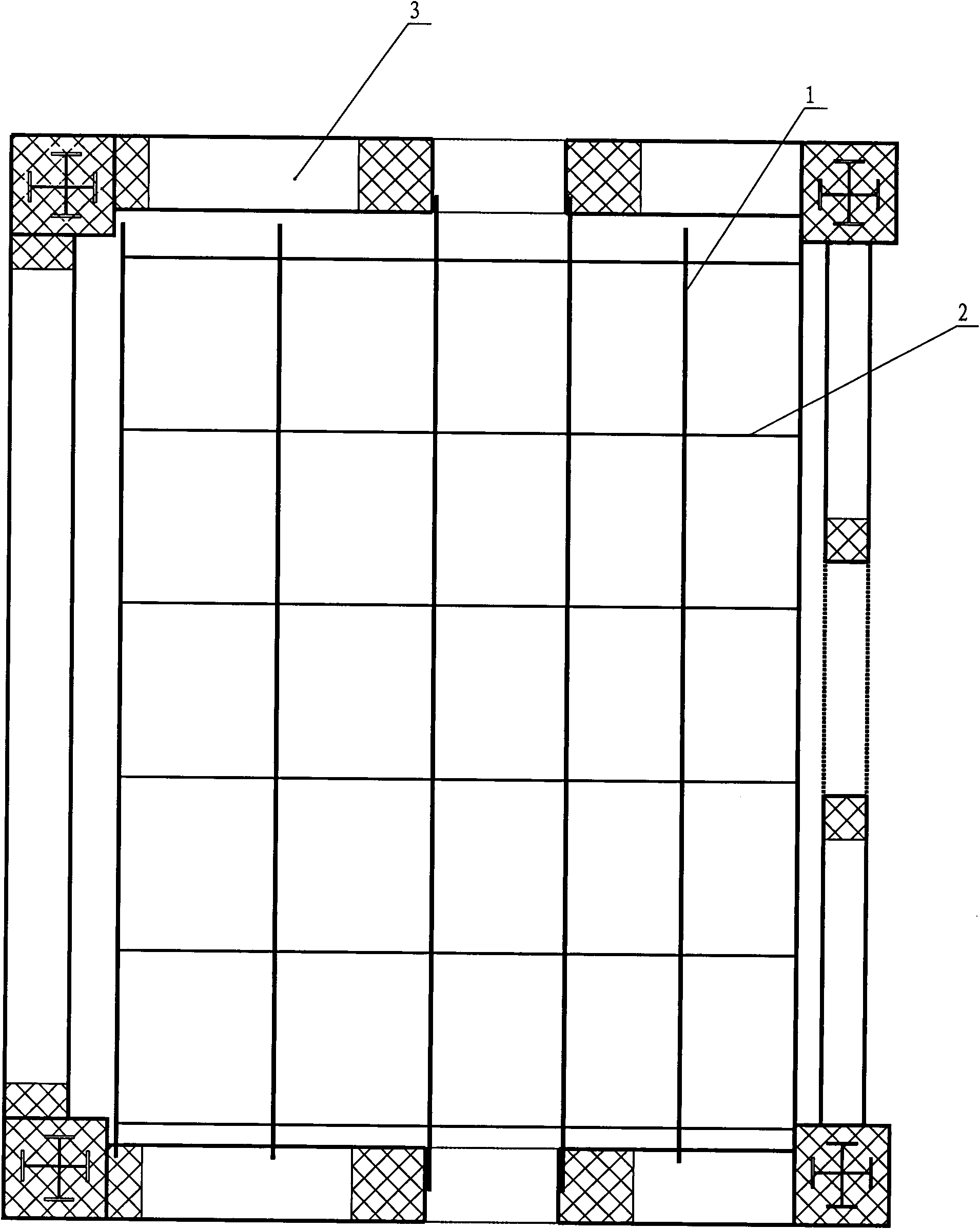

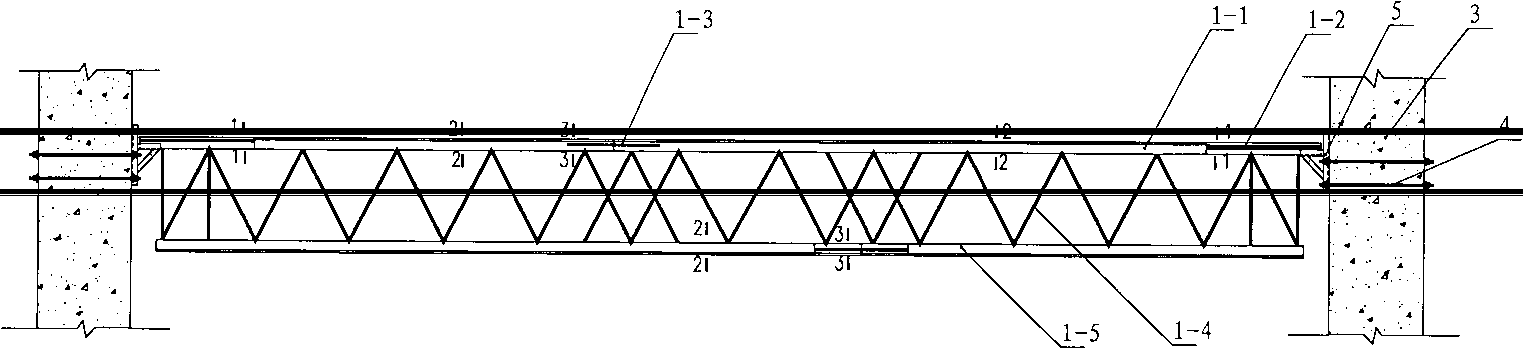

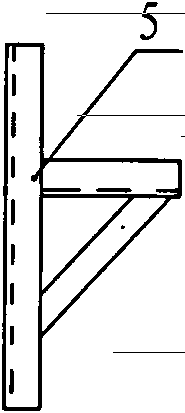

[0022] Embodiment: a simultaneous construction system of upper and lower horizontal structures in a core tube, the system contains a hard protective layer and a hard protective conversion layer, the hard protective layer is located on the upper part of the hard conversion layer, and the hard protective layer The layer consists of several parallel trusses, each of which is fixedly connected to the side wall of the core tube at both ends, and connecting side pieces are provided between adjacent trusses, and the hard protective layer is covered with scaffolding and iron sheets; The hard transition layer includes several parallel I-steel main beams, the two ends of each I-steel main beam are inserted into the side wall of the core tube, and angle steel sub-beams are connected between adjacent I-steel main beams , the top of the hard protective conversion layer is scaffolding board and iron sheet.

[0023] The truss includes an upper beam and a lower beam, and several diagonal brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com