Camshaft bearing cap of engine

A technology of bearing caps and camshafts, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve problems affecting speed, etc., and achieve the effects of fast response, good connection strength and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

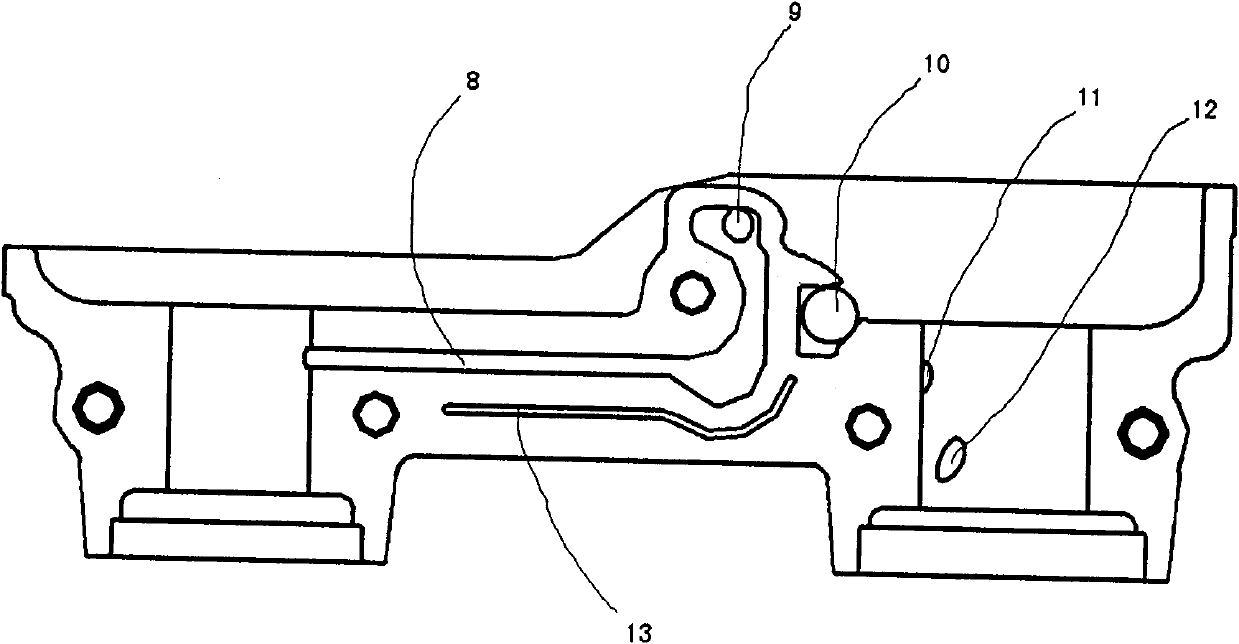

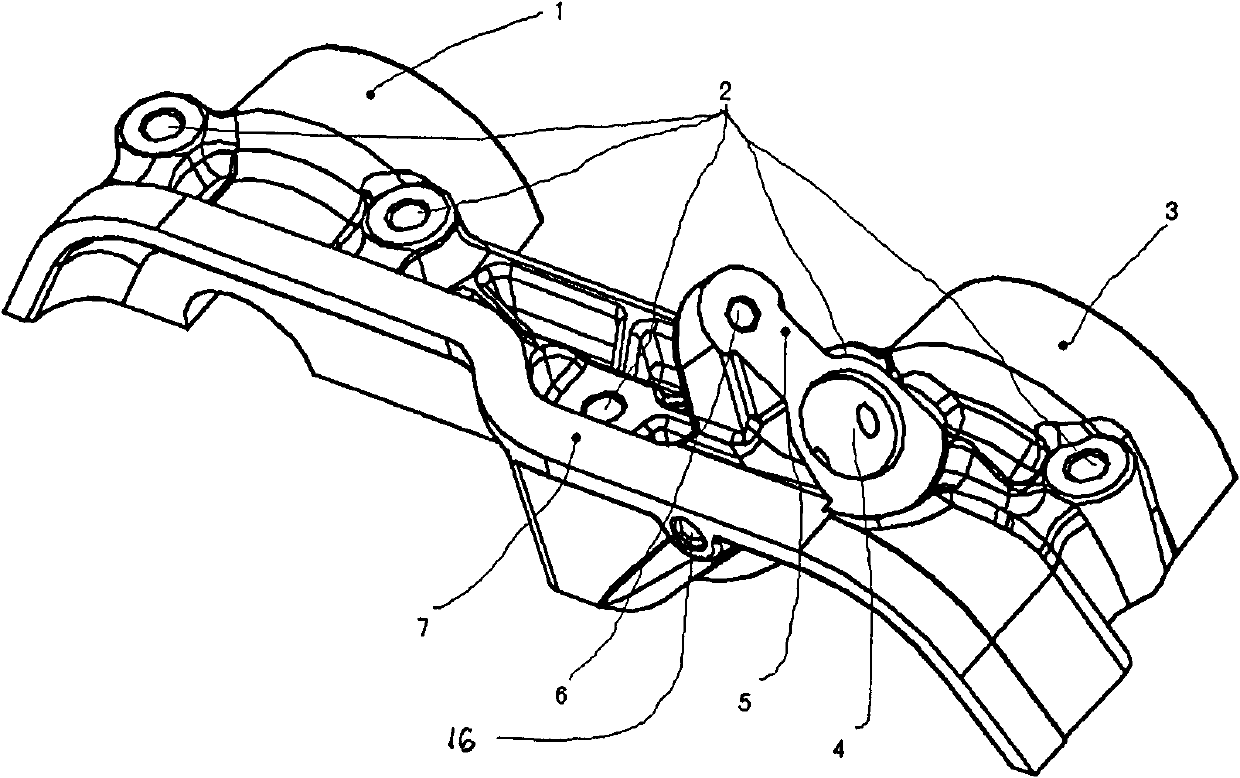

[0018] Such as figure 1 and figure 2 As shown, the diameter of the camshaft hole 3 on the intake side of the shaft cover is 33mm, the diameter of the camshaft hole 1 on the exhaust side is 28mm, and the larger design of the camshaft hole 3 on the intake side ensures that there is enough space for VVT oil supply , Oil return system.

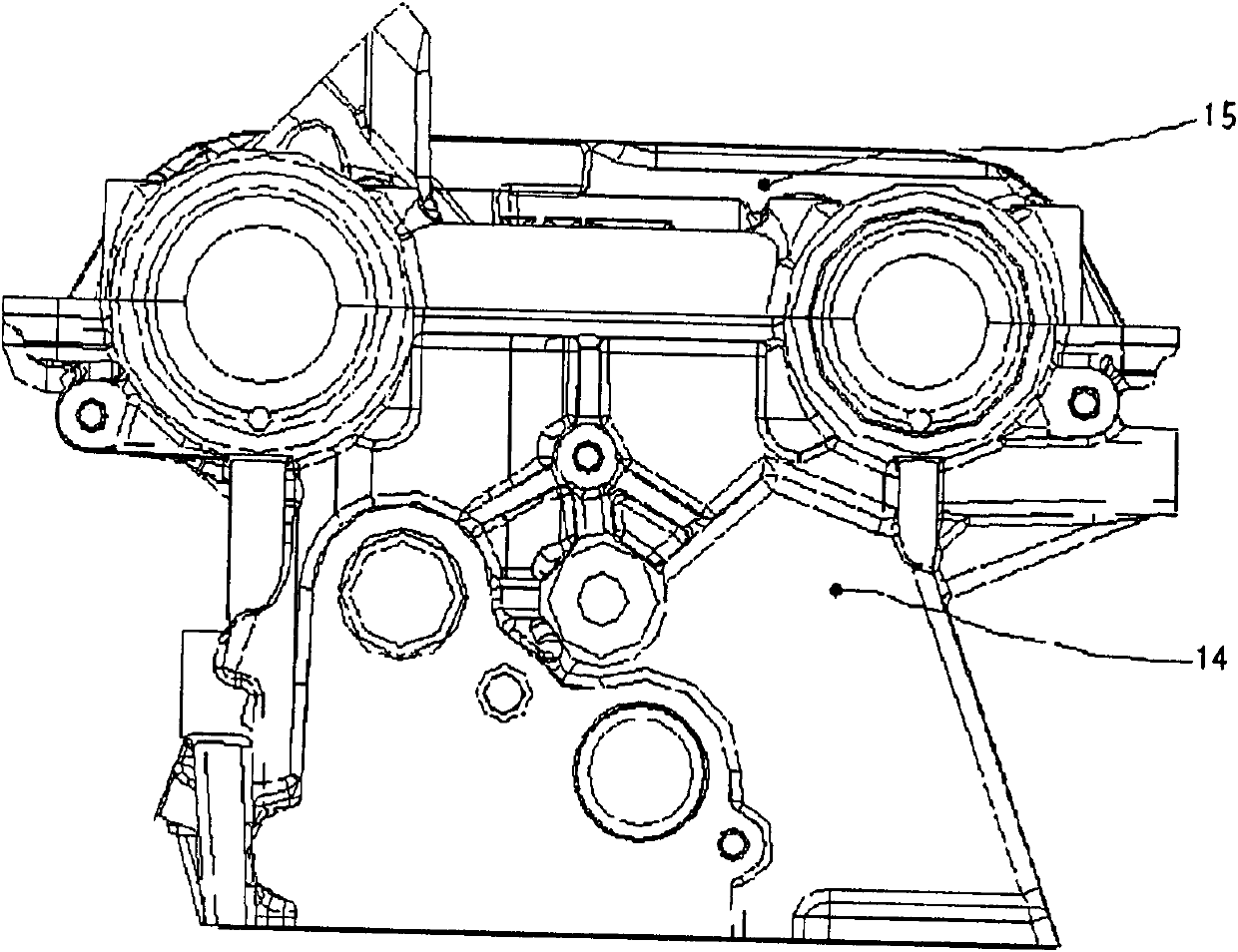

[0019] Five connecting bolt through holes 2 that are not on the same straight line are designed on the shaft cover body for the connection of the shaft cover 15 and the cylinder head 14 (see image 3 ). Among them, a connecting bolt hole in the middle is offset to the side of the OCV valve installation hole, and is located near the oil supply hole 9, which can effectively seal the surrounding area of the oil supply hole. The fact that the five fixing bolts are not on the same straight line can also increase the joint stiffness of the shaft cover and reduce the deformation of the shaft cover when the engine is working.

[0020] The shaft cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com