Bituminous pavement material hydrodynamic pressure washing tester

A technology of hydrodynamic pressure and scour test, which is used in the analysis of materials, the use of repetitive force/pulse force to test the strength of materials, instruments, etc. The test results are stable and reliable, with strong comparability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

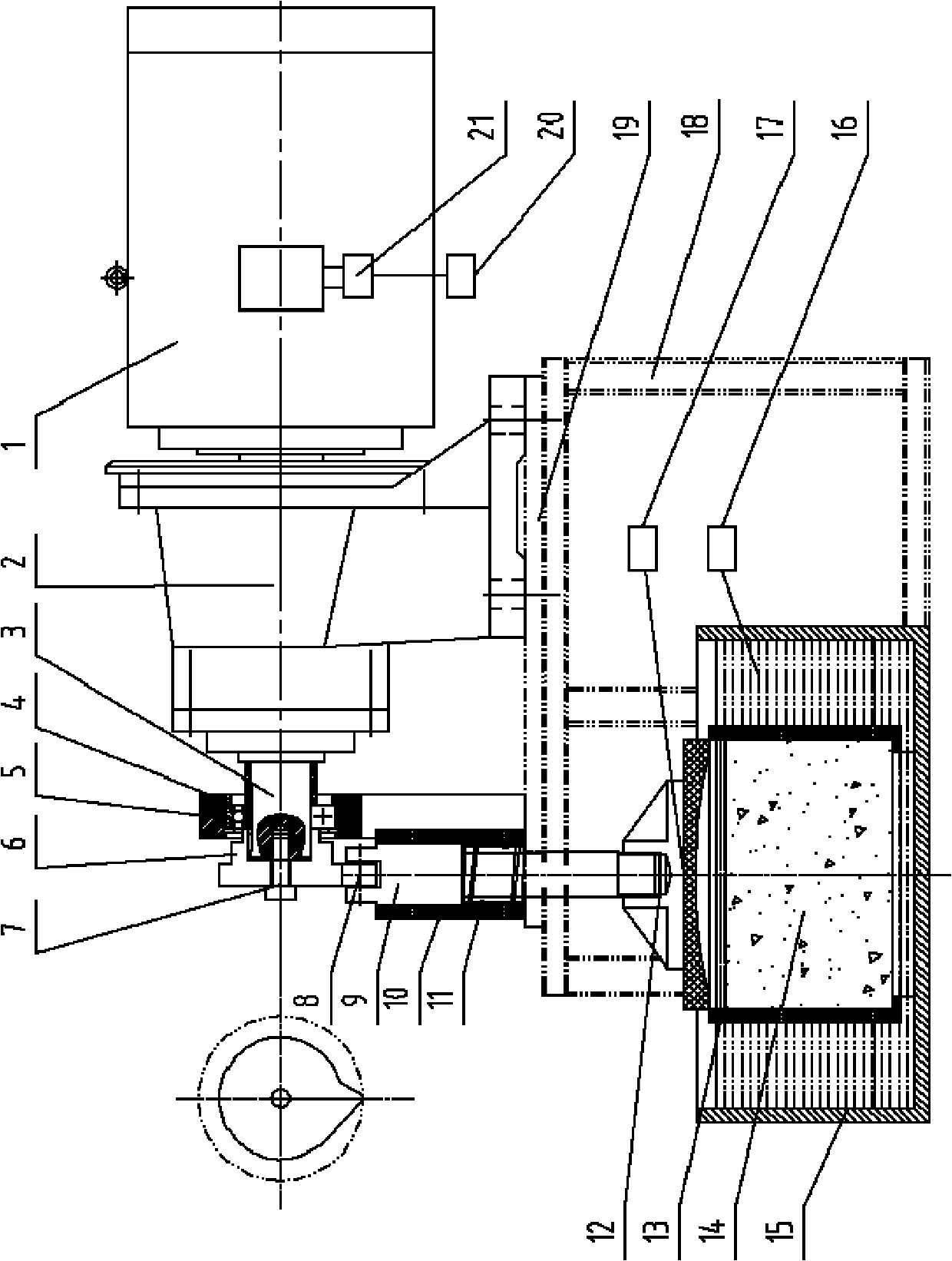

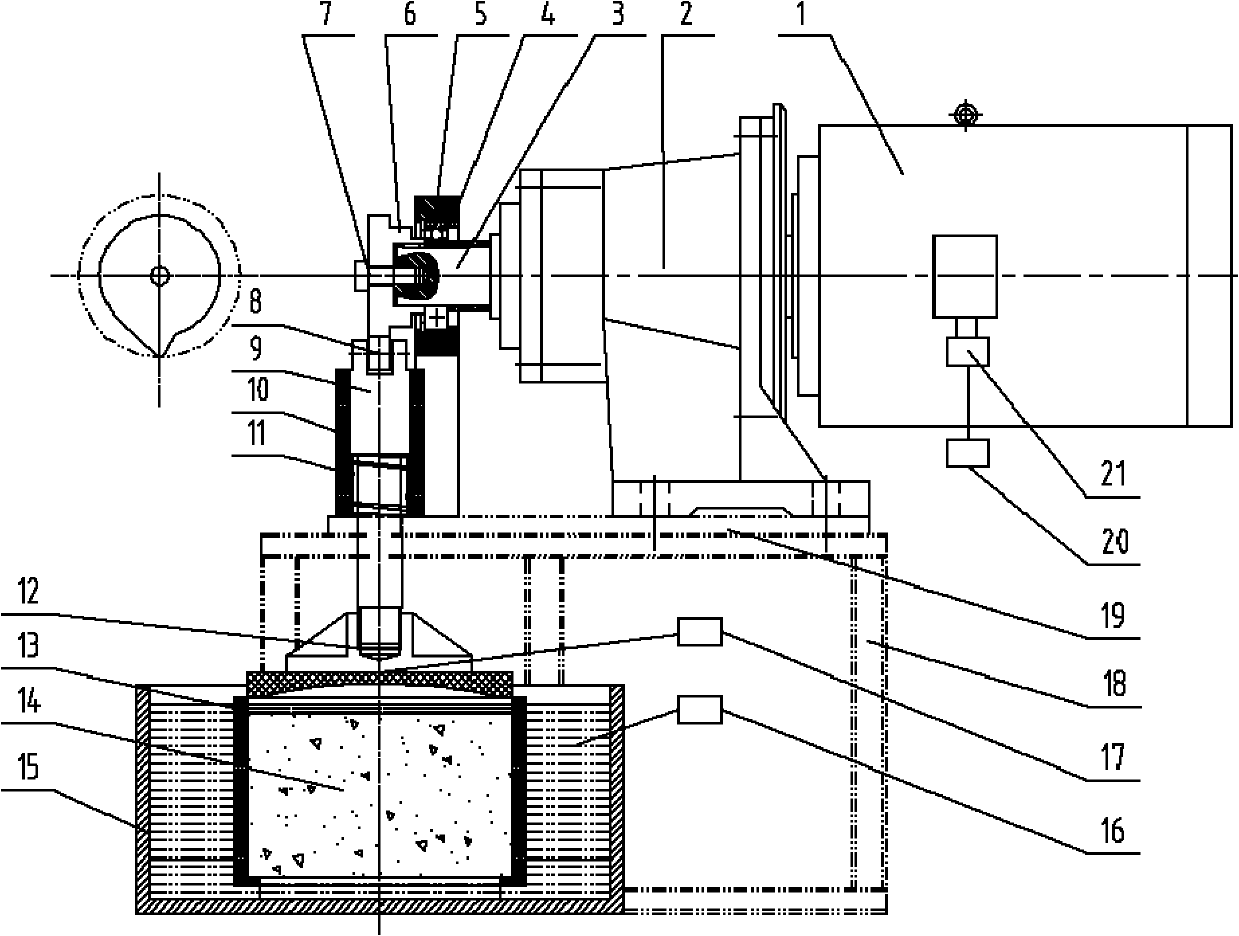

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

[0018] see figure 1 , the asphalt pavement material hydrodynamic pressure scouring tester of the present invention includes a frame 18 and a horizontal bottom plate 19 located on the top of the frame 18, and the horizontal bottom plate 19 is fixedly provided with a motor 1 and a reducer 2 assembled together. The motor 1 is connected with a frequency converter 21 , and the frequency converter 21 is also connected with a time controller 20 . The motor of the present invention can be a three-phase asynchronous motor with a power of 0.75kW.

[0019] The output shaft 3 of the speed reducer 2 is connected with a cam mechanism through the bearing support 4, the bearing 5 and the hold-down bolt 7, and the cam 6 of the cam mechanism is driven by the motor 1 through the accelerator 2. As shown in the figure, in a specific embodiment of the present invention, the output shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com