Special detecting machine for automobile circuit breaker

A technology of circuit breakers and automobiles, which is applied in the direction of circuit breaker testing, etc., which can solve the problems of qualified, lack of test systems for automobile breakers, and failure to guarantee automobile breakers, so as to ensure personal safety, avoid accident expansion, and cut off fault current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

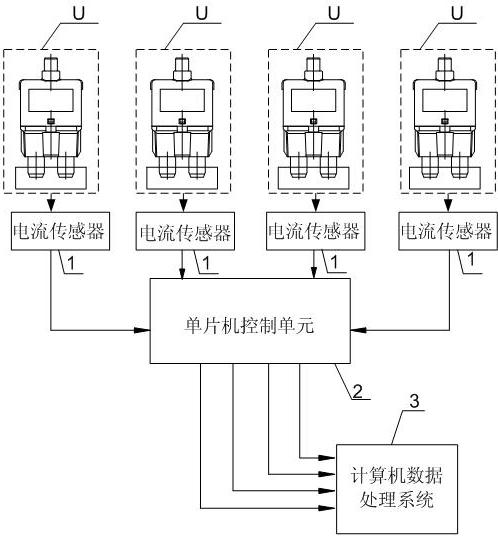

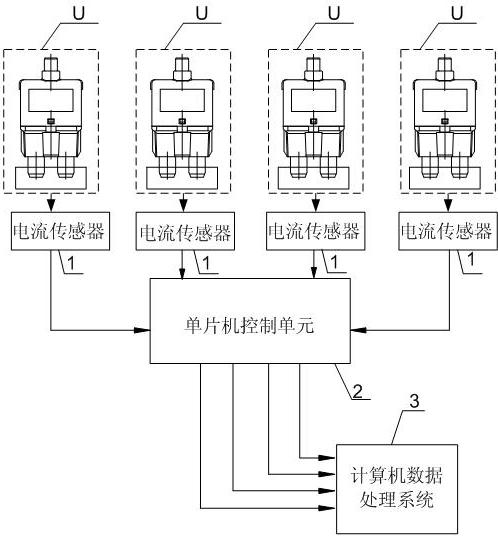

[0009] Specific implementation mode 1: according to the instructions attached figure 1 To specifically describe this embodiment, a special inspection machine for automotive circuit breakers described in this embodiment includes: a current sensor 1 , a single-chip control unit 2 and a computer data processing system 3 , the single-chip controls The unit 2 has a data input end and a data output end, the computer data processing system 3 has a plurality of data input ends, the current output end of the current sensor 1 is connected with the data input end of the single-chip control unit 2, the single-chip microcomputer The data output end of the control unit 2 is connected with a data input end of the computer data processing system 3,

[0010] The single-chip control unit 2 is used to collect the current data of the NX ampere output by the car breaker U to the current sensor 1, and is also used to record the disconnection time, and transmit the recorded disconnection time to the...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the special inspection machine described in Embodiment 1 further includes a plurality of current sensors 1. Corresponding to the plurality of current sensors 1, the special inspection machine The single-chip control unit 2 in the MCU also has multiple data input terminals and multiple data output terminals, the multiple data output terminals are in one-to-one correspondence with the multiple data input terminals, and the current output terminal of each current sensor 1 It is connected with a data input end of the single-chip control unit 2 , and each data output end of the single-chip control unit 2 is connected with a data input end of the computer data processing system 3 in a one-to-one correspondence.

specific Embodiment approach 3

[0013] Specific embodiment 3: This embodiment is a further description of specific embodiment 2. The number of current sensors 1 further included in the special inspection machine described in specific embodiment 2 is 4. Corresponding to the 4 current sensors 1, so The single-chip control unit 2 in the special inspection machine also has four data input terminals and data output terminals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com