Automatic forming machine for rotor coil of wind generating set

A technology for wind turbines and rotor coils, which is applied in the manufacture of motor generators, electric components, electrical components, etc. It can solve the problems of increased consumption of personnel, tooling and site occupation, difficulty in ensuring coil quality and productivity, and different use efforts. , to achieve the effect of compact and simple structure, precise geometric dimension of coil space, and smooth curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

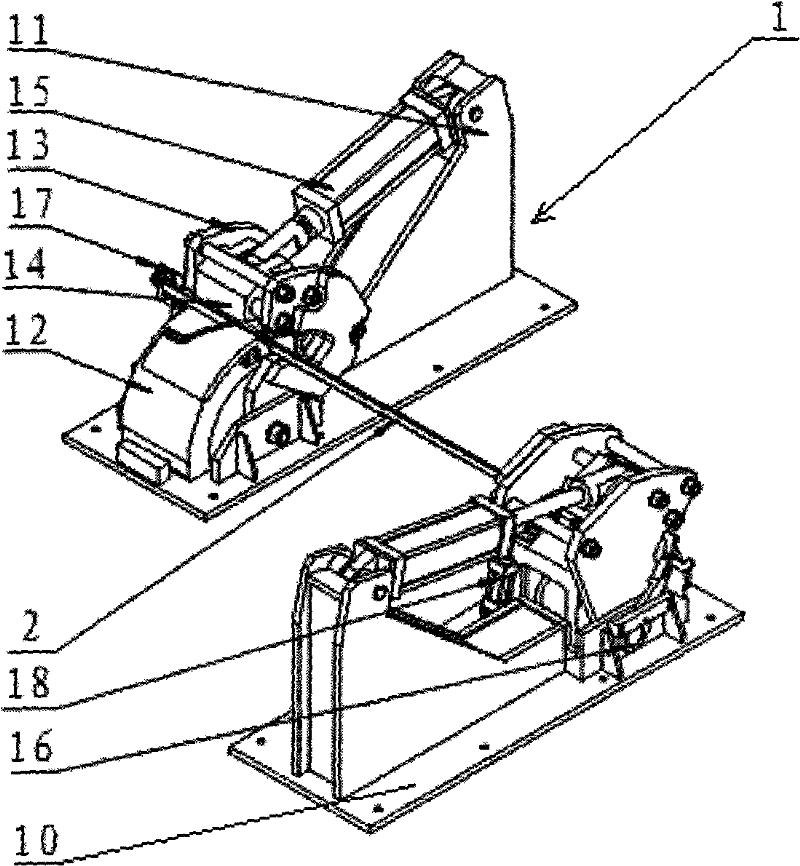

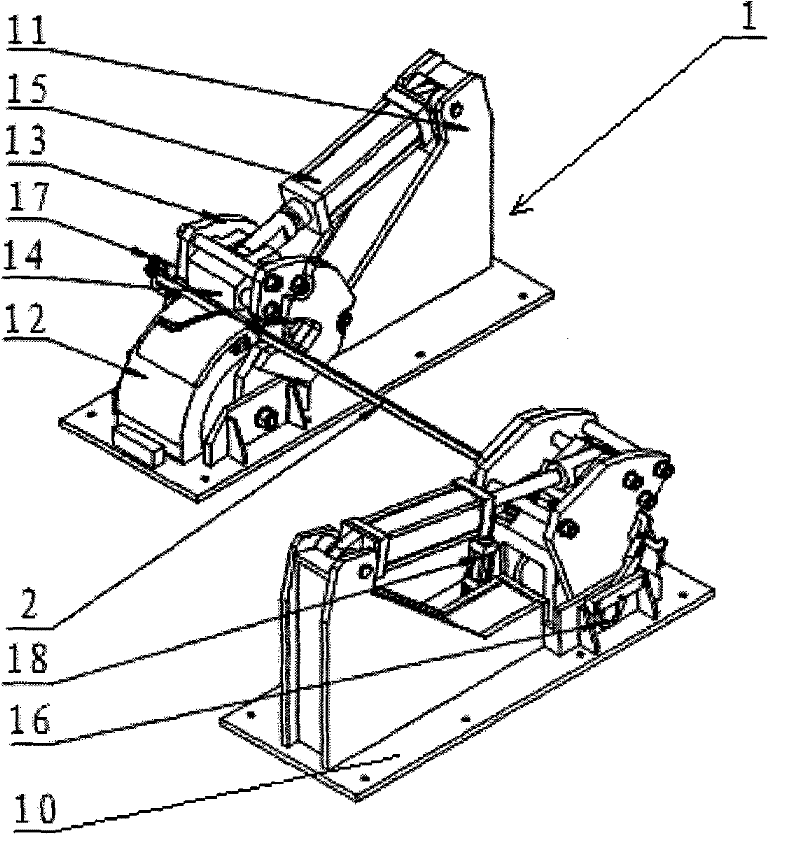

[0016] Such as figure 1 As shown, an automatic forming machine for rotor coils of a wind power generating set includes a main control hydraulic station and a pair of actuators 1 set in opposite phases. The actuators 1 include a base 10, a frame 11, a fixed mold 12, a Arm 13, movable mold 14 and active forming oil cylinder 15, described frame 11 is fixed on the front portion of base, described fixed mold 12 is fixed on the rear portion of base 10, described active arm 13 is connected with a rotating shaft 16 The fixed mold 12 is pivotally connected, and the movable mold 14 is arranged on the main arm 13. The movable mold 14 is opposite to the forming surface of the fixed mold 12 and respectively adapted to the shape of the upper and lower curved surfaces of the wind turbine rotor coil. One end of the active forming oil cylinder 15 is pivotally connected to the frame 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com