Apparatus and method for supporting, positioning and rotating a substrate in a processing chamber

一种处理腔室、基板的技术,应用在电气元件、电路、半导体/固态器件制造等方向,能够解决提高复杂度和成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

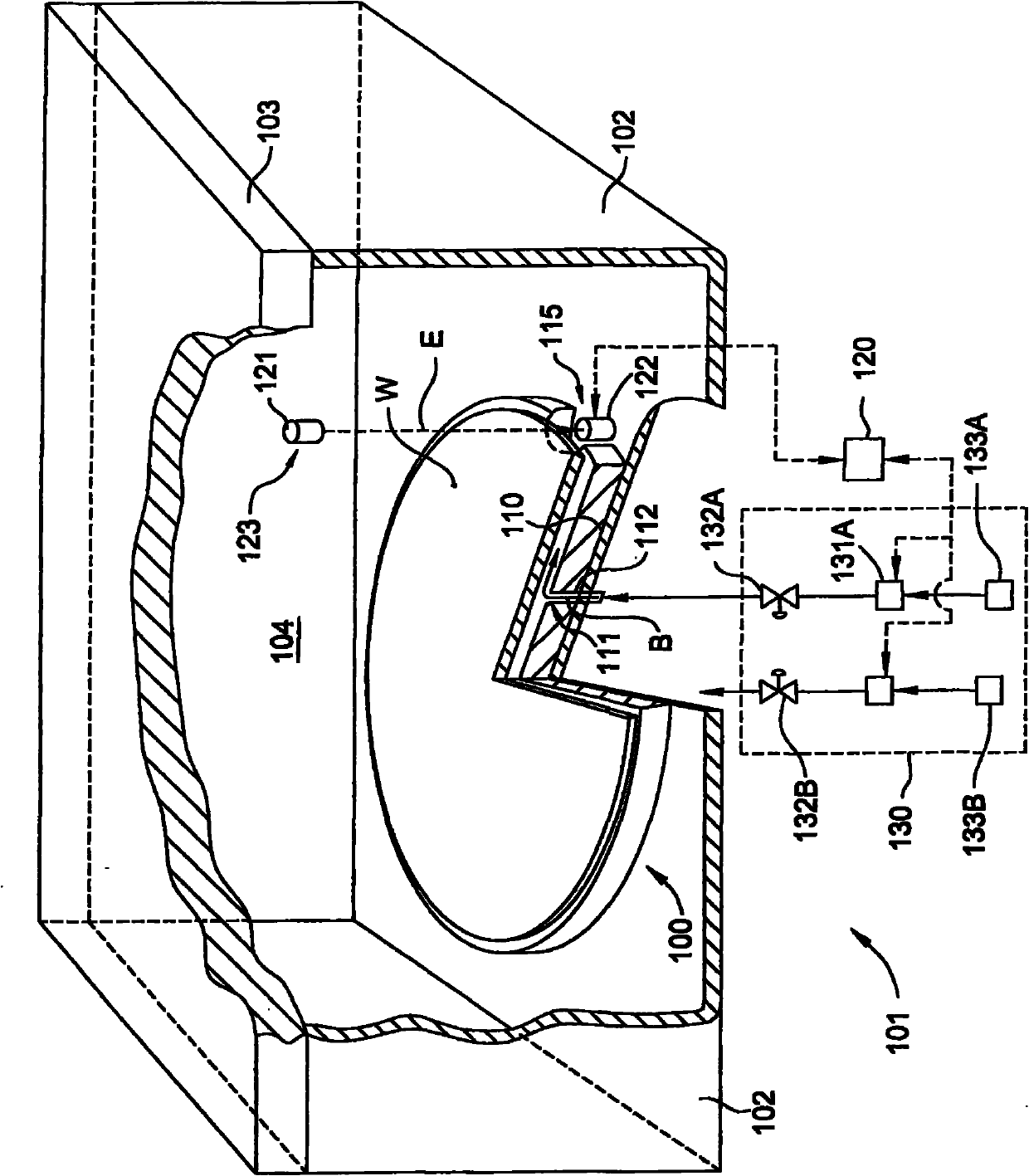

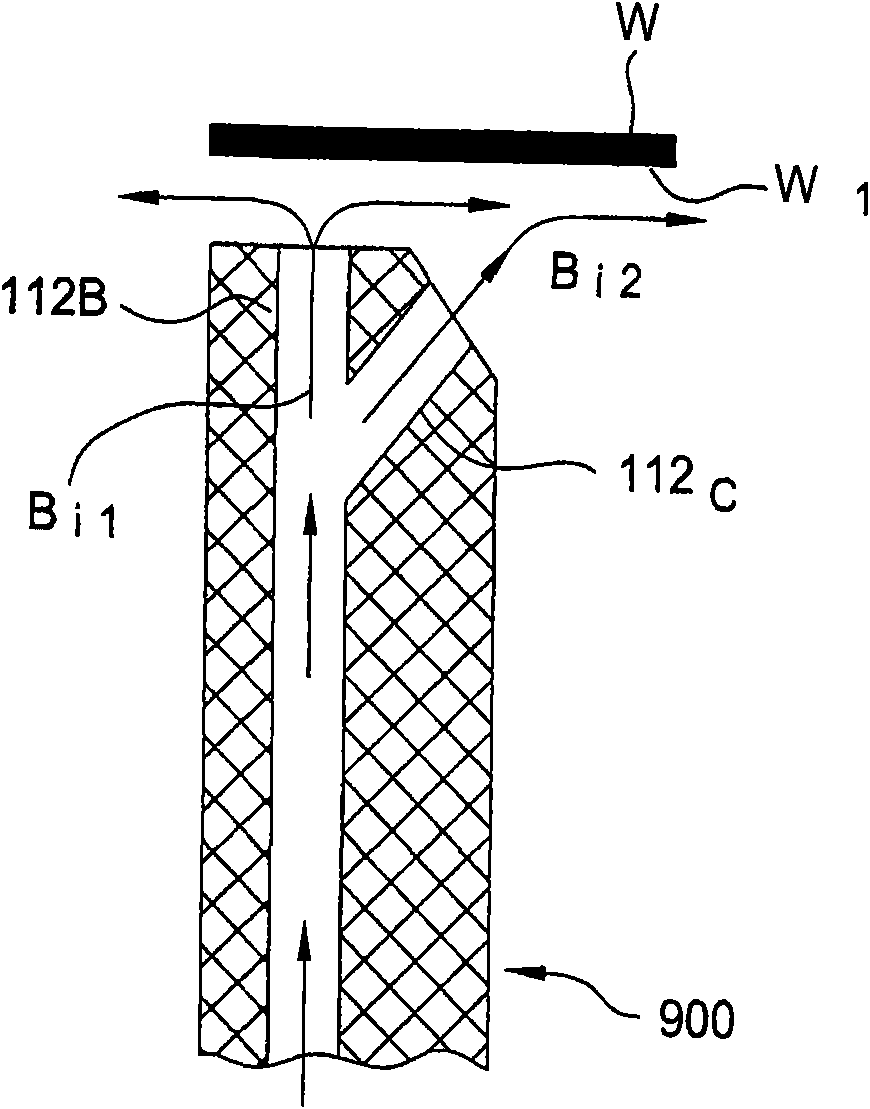

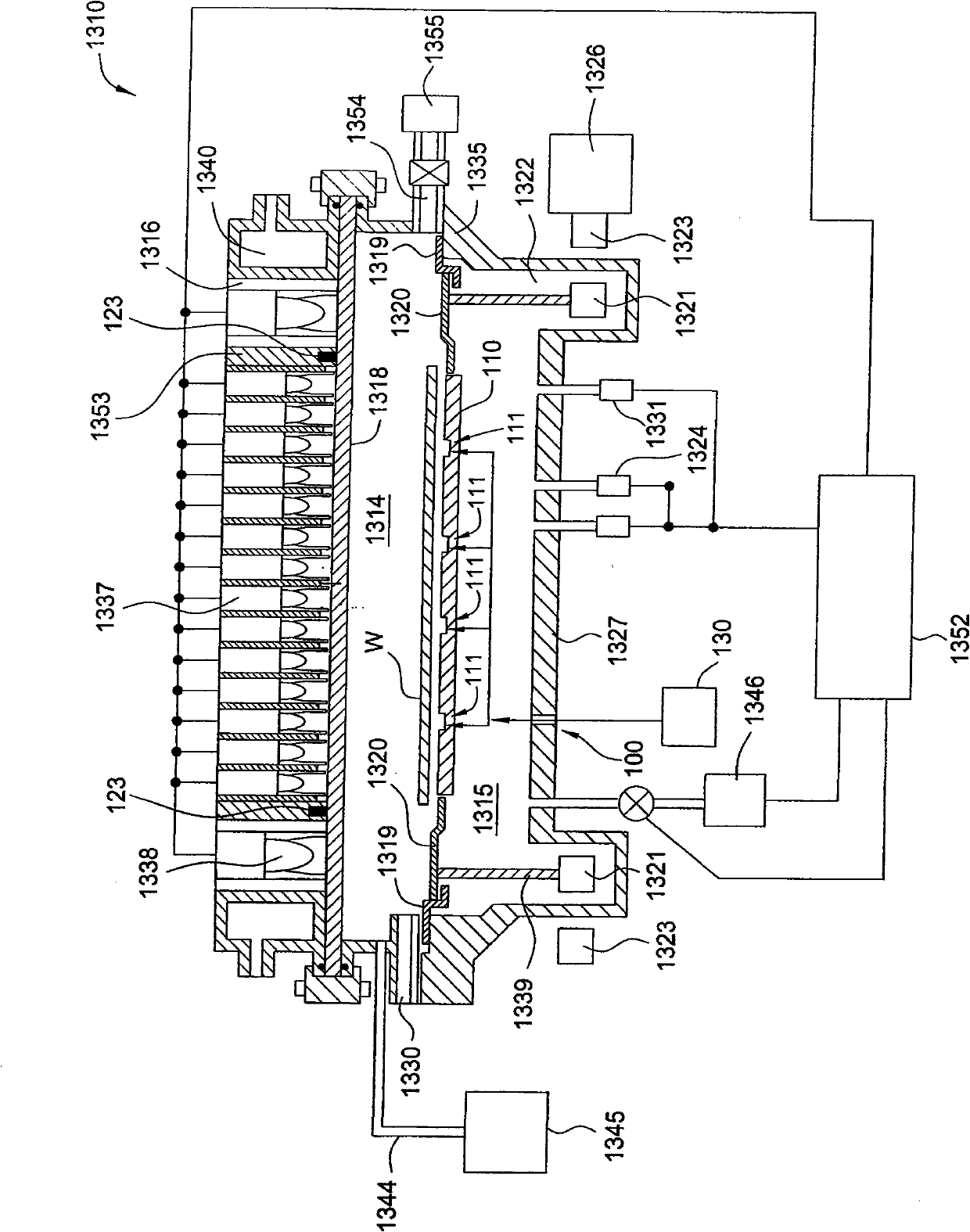

[0049] Embodiments of the invention encompass methods, apparatus, and systems for supporting, positioning, and rotating substrates during processing. Embodiments of the invention also include methods of controlling heat transfer between a substrate and a substrate support within a processing chamber. During one or more processing steps, such as rapid thermal processing (RTP) processes, chemical vapor deposition (CVD) processes, physical vapor deposition (PVD) processes, atomic layer deposition (ALD) processes, wet cleaning processes (such as taken from Tempest by Applied Materials TM processing chamber), dry etching process, and / or laser annealing, the apparatus and method do not require complex, expensive and often unreliable components to properly position and rotate the substrate. Substrates that can be processed using the methods, apparatus, and systems include 200 millimeter (mm), 300 mm or larger single crystal silicon (Si), multi-crystalline (multi-crystalline) silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com