Vibrating table for centrifugal machine

A technology of vibrating table and centrifuge, which is applied in the direction of centrifuge, etc., can solve problems such as the displacement of moving parts of the vibrating table, and achieve the effect of simple control, low density and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

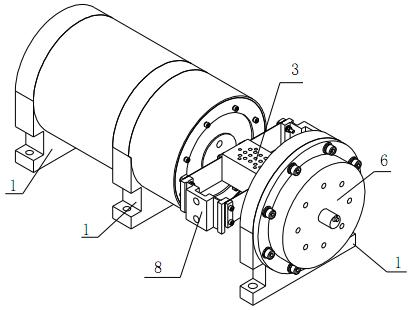

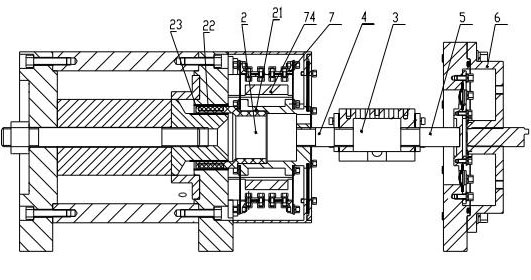

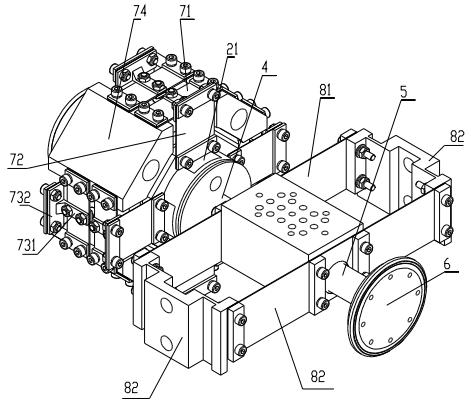

[0043] With reference to accompanying drawing, further illustrate the present invention:

[0044] A vibrating table for a centrifuge, including a frame 1, the frame 1 is provided with a vibrating table moving coil 2 that generates vibrations and a test platform 3 for carrying workpieces to be tested, and the left end of the test platform 3 passes through the platform The push rod 4 is linked with the moving coil 2 of the vibrating table;

[0045] The right end of the test platform 3 is connected to a deviation-correcting mechanism 6 to prevent the vibrating table moving coil 2 from excessively deflecting in the axial direction through the deviation-correcting push rod 5;

[0046] The upper periphery of the aluminum frame 21 of the moving coil of the vibrating table is provided with a support mechanism 7 that prevents the circumferential torsion or radial displacement of the moving coil.

[0047] The support mechanism 7 includes a hollow reed support 74 fixed to the frame 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com