Automatic pipe cutting and chamfering device

An automatic cutting and chamfering device technology, which is applied in the field of mechanical processing, can solve the problems of uneven chamfering, high cost, and low efficiency, and achieve the effects of high automation, high processing efficiency, simple structure, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

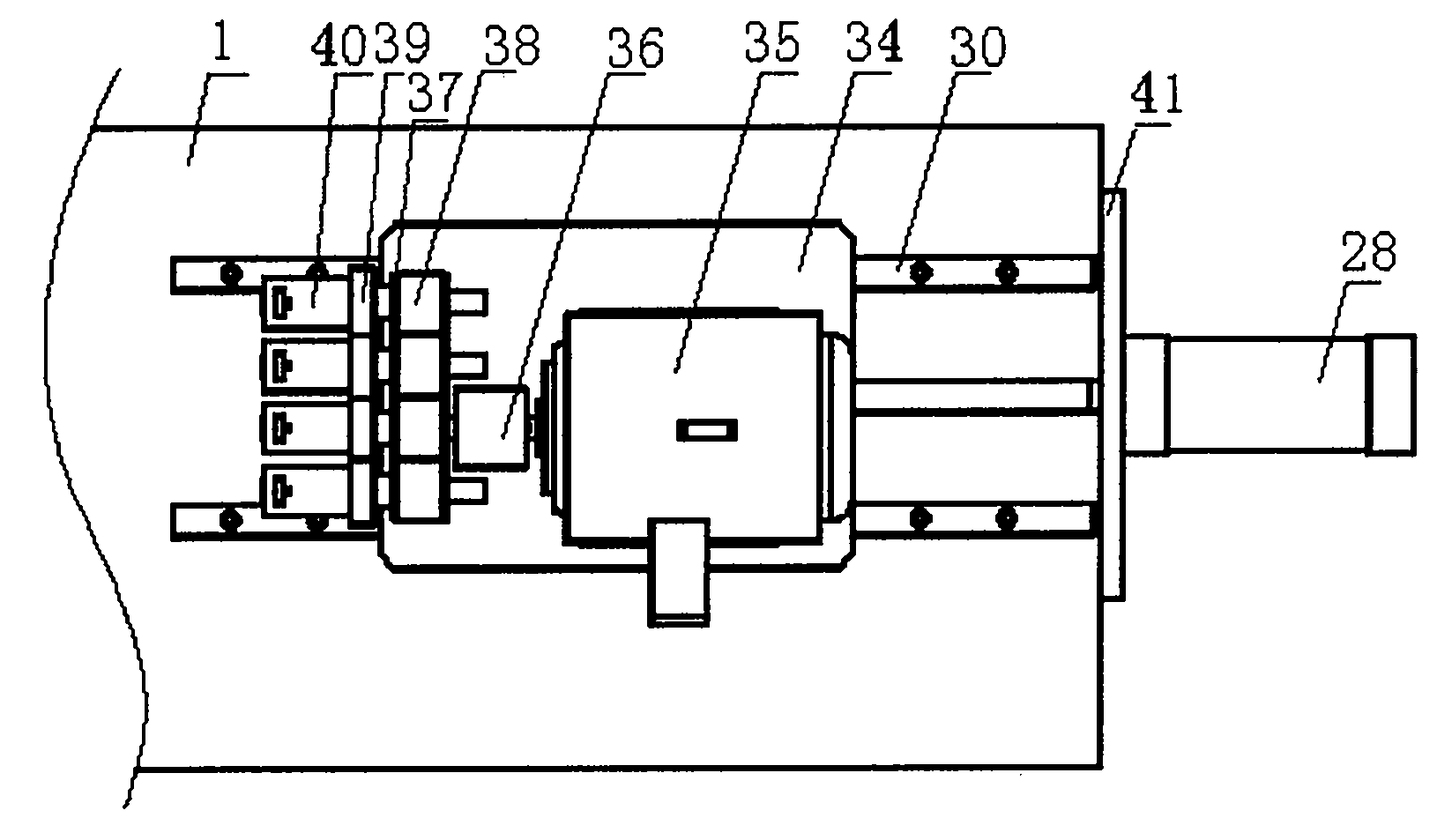

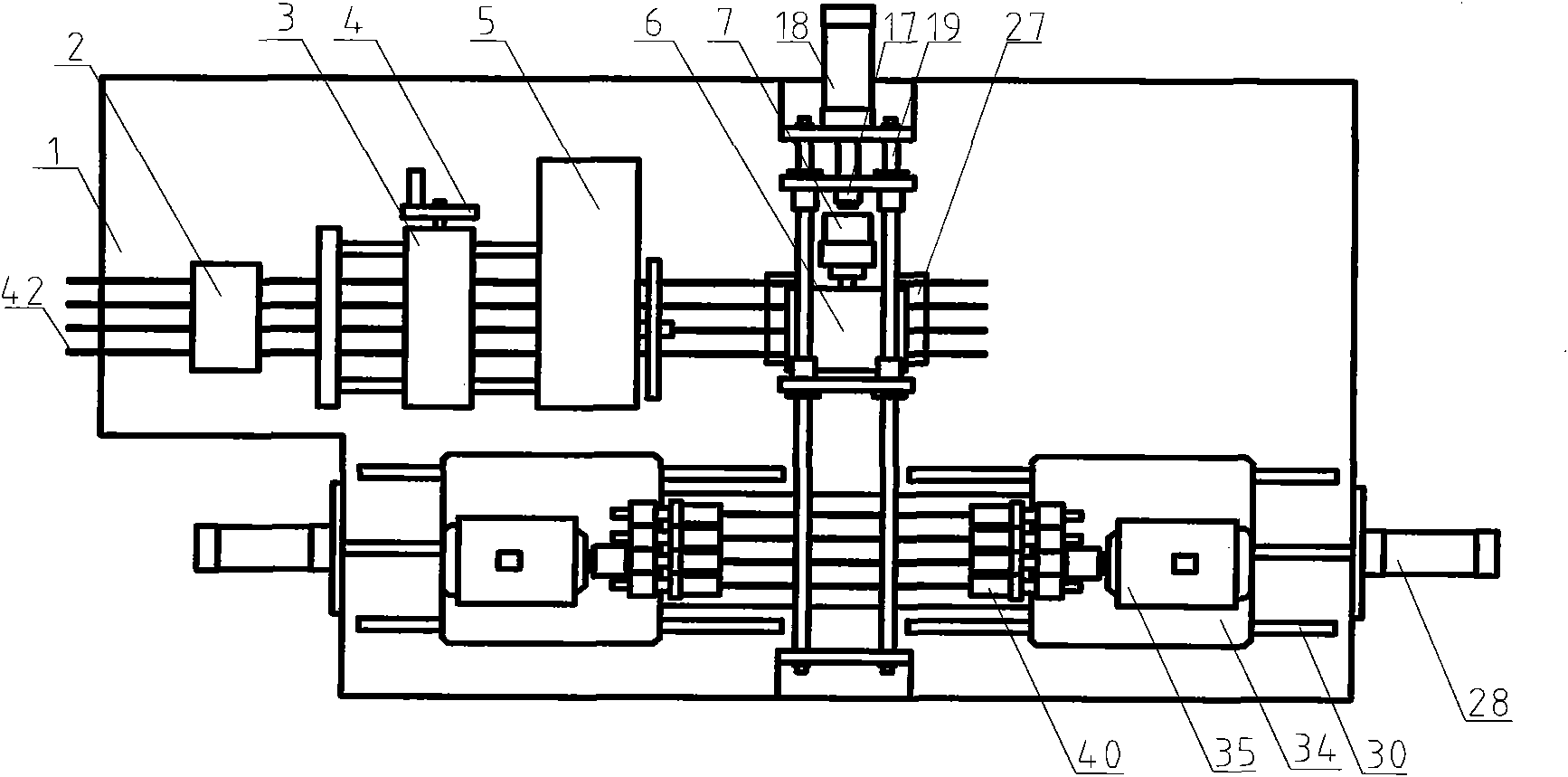

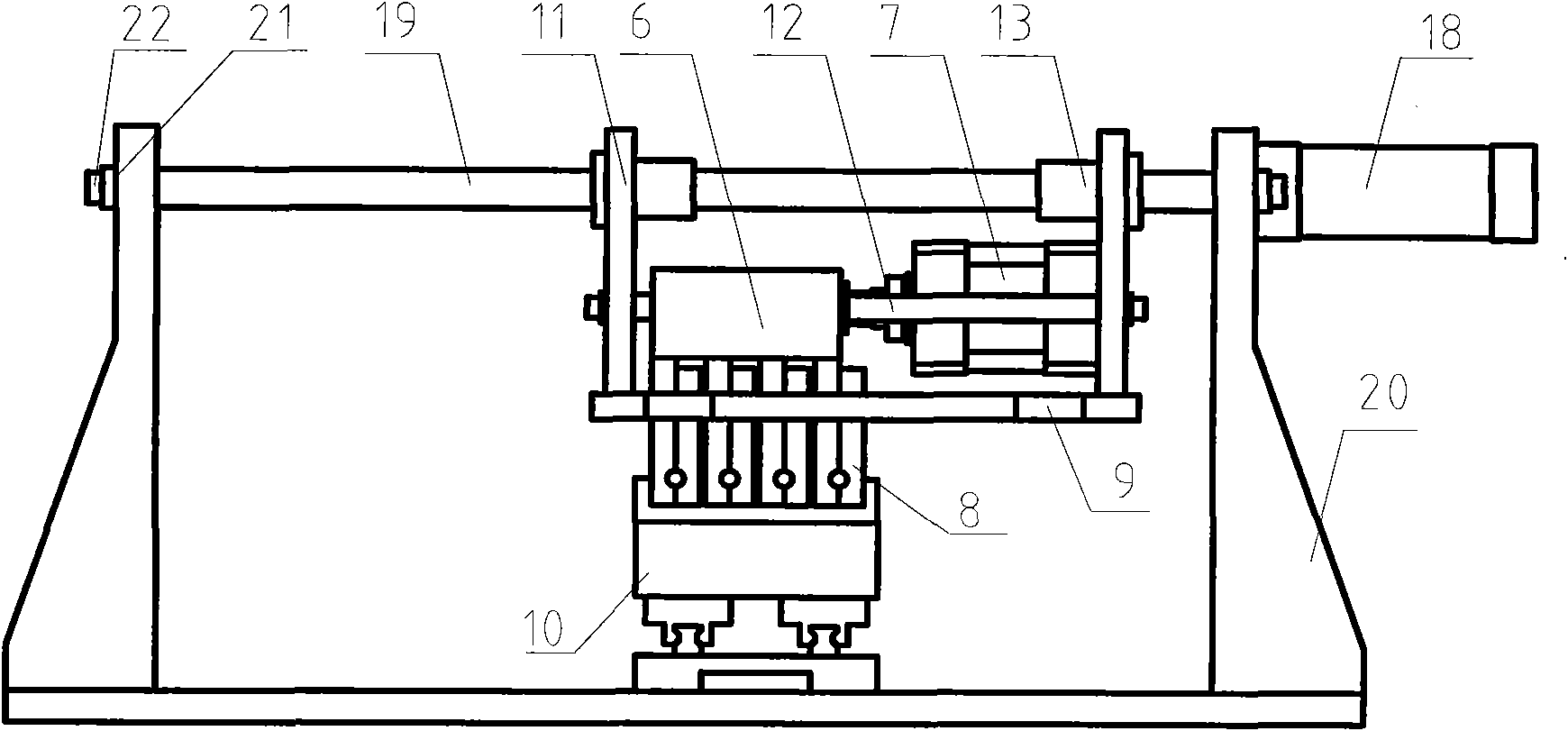

[0043] The present invention is described in detail below in conjunction with accompanying drawing

[0044] Such as figure 1As shown, an automatic pipe cutting and chamfering device includes a frame 1, a straightening mechanism 2, a handwheel sliding mechanism 3, a handwheel 4, a cutting mechanism 5, a pushing mechanism and a chamfering mechanism. Wherein straightening mechanism 2, handwheel sliding mechanism 3, handwheel 4 and cutting mechanism 5 all adopt prior art, are installed on the frame 1 successively; Pushing mechanism is positioned at cutting mechanism 5 one ends, and clamper in pushing mechanism The center line of the pipe material clamping groove on the top coincides with the center line of the pipe material 42 placed in the cutting mechanism 5 . The chamfering mechanism is located on one side of the cutting mechanism 5, parallel to the cutting mechanism 5, and perpendicular to the pushing mechanism.

[0045] Such as figure 2 As shown, the pushing mechanism inc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap