Ultra-thin wearing layer bituminous concrete material for paving bridge deck and preparation method thereof

A technology for asphalt concrete and bridge deck pavement, which is applied in the field of road construction materials, can solve problems such as permanent deformation of aggregates, decreased drainage capacity, loss of anti-skid ability of ultra-thin wear layers, etc., and achieve good anti-skid performance and good high temperature stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

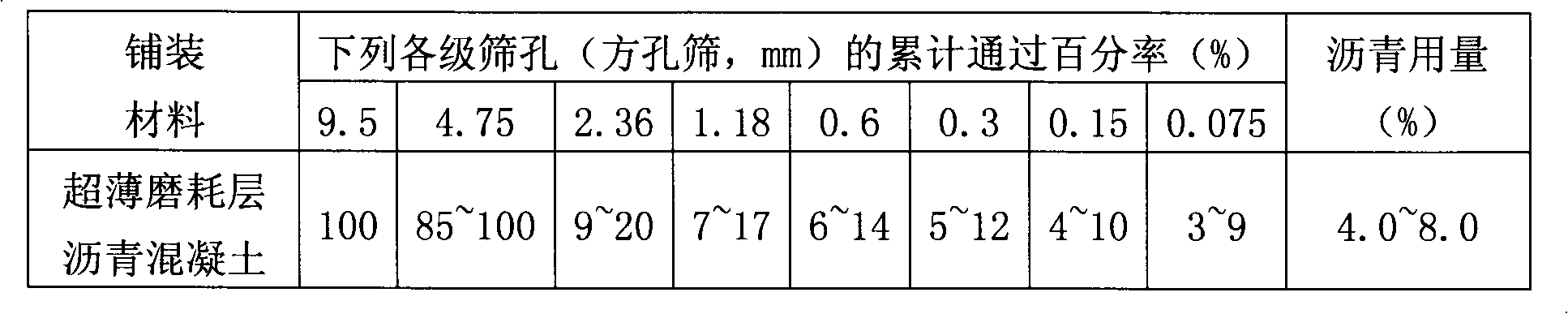

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Each raw material is calculated by weight ratio, 10 parts of epoxy resin, 50 parts of base asphalt with curing agent added, 1000 parts of basalt aggregate, and 100 parts of mineral filler. First, heat 10 parts of epoxy resin to 80±5°C and mix with 50 parts of matrix asphalt with curing agent added to 125±5°C and mix evenly to prepare epoxy asphalt binder; The finished epoxy asphalt binder is added to 1000 parts of basalt aggregates preheated to 110-130 °C, and mixed in a mixing pot. The mixing time is not less than 20 seconds, and then 100 parts of mineral fillers are added to the mixing pot. Mix in the mixing pot for no less than 60 seconds, and the bridge deck ultra-thin wear-resistant layer asphalt concrete is prepared.

[0045] Put the above-mixed epoxy asphalt mixture into the transportation equipment, and count the discharge time. During the transportation, insulation measures must be taken. Transport to the construction site and calculate the paving s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com