Method for alloying vanadium in molten steel by using ferrovanadium fine powder in RH station

A vanadium alloying and fine powder technology is applied in the field of vanadium alloying to achieve the effect of reducing production costs and rapid alloying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

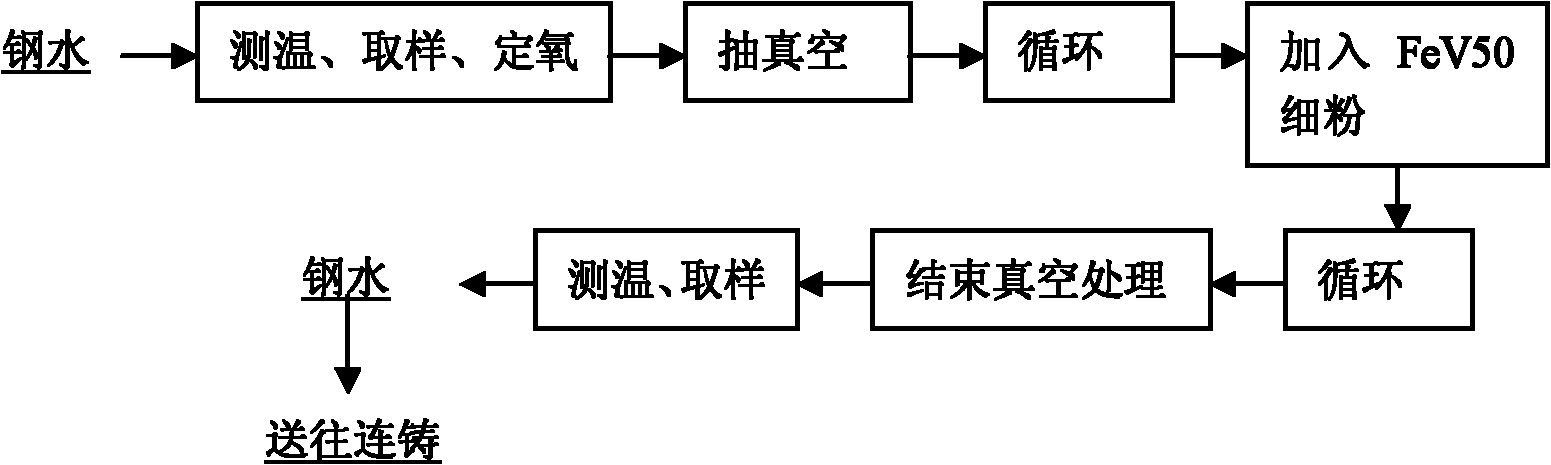

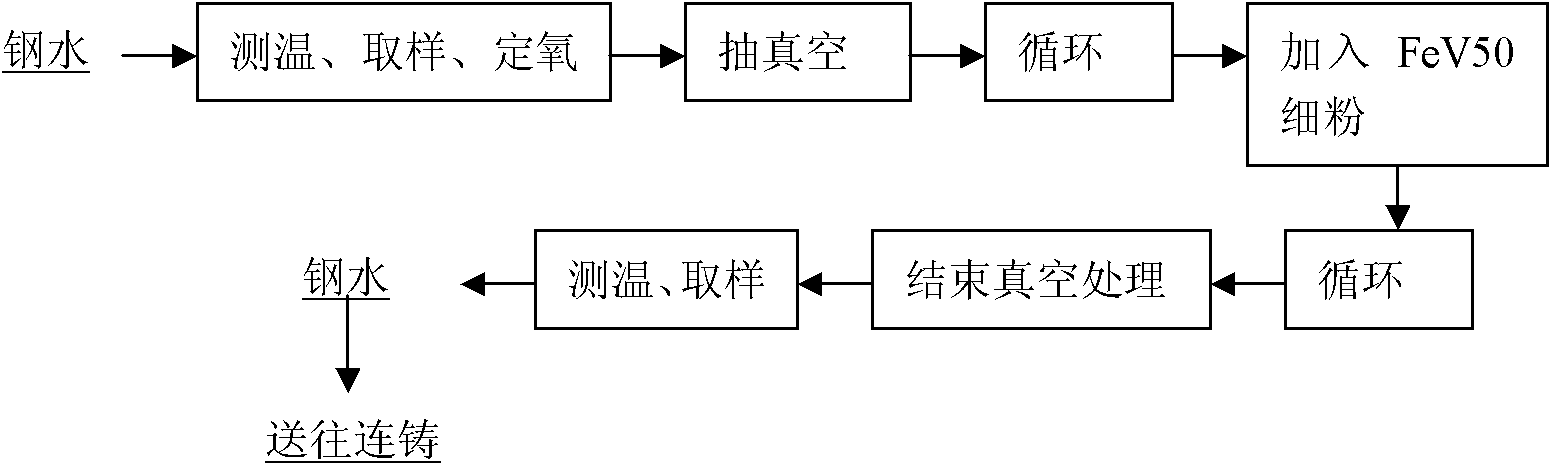

Image

Examples

Embodiment 1

[0019] Embodiment one uses the method of the present invention to carry out vanadium alloying of molten steel

[0020] Prepare particle size and be the FeV50 fine powder of 5~15 millimeters, its composition is: V 50%, C 0.15%, Si0.3%, P 0.03%, S 0.03%, Al 1.3%, all the other are Fe (weight percent). The molten steel enters the RH vacuum treatment station, and after temperature measurement, sampling, and oxygen determination, it is vacuumized, and the molten steel is circulated for 10 minutes under the condition of a vacuum of 2 millibars (mbar), and the molten steel is deoxidized and dehydrogenated, and then the particle size is FeV50 fine powder of 5-15 mm is added from the silo to the molten steel for vanadium alloying. After vanadium alloying, the circulation continues for 3 minutes, then the vacuum treatment is completed, the temperature is measured, and the molten steel is sent to the continuous casting process after sampling.

[0021] Among them, the amount of molten ste...

Embodiment 2

[0022] Embodiment two uses the method of the present invention to carry out vanadium alloying of molten steel

[0023] Prepare particle size and be the FeV50 fine powder of 5~15 millimeters, its composition is: V 50%, C 0.15%, Si0.3%, P 0.03%, S 0.03%, Al 1.3%, all the other are Fe (weight percent). The molten steel enters the RH vacuum treatment station, and after temperature measurement, sampling, and oxygen determination, it is vacuumized, and the molten steel is circulated for 8 minutes under the condition of a vacuum of 1 millibar (mbar), and the molten steel is deoxidized and dehydrogenated, and then the particle size is FeV50 fine powder of 5-15 mm is added from the silo to the molten steel for vanadium alloying. After vanadium alloying, the circulation continues for 5 minutes, then the vacuum treatment is completed, the temperature is measured, and the molten steel is sent to the continuous casting process after sampling.

[0024] Among them, the amount of molten steel...

Embodiment 3

[0025] Embodiment three uses the method of the present invention to carry out vanadium alloying of molten steel

[0026] Prepare particle size and be the FeV50 fine powder of 5~15 millimeters, its composition is: V 50%, C 0.15%, Si0.3%, P 0.03%, S 0.03%, Al 1.3%, all the other are Fe (weight percent). The molten steel enters the RH vacuum treatment station, after temperature measurement, sampling, and oxygen determination, it is vacuumized, and the molten steel is circulated for 12 minutes under the condition of a vacuum of 3 millibars (mbar), and the molten steel is deoxidized and dehydrogenated, and then the particle size is FeV50 fine powder of 5-15 mm is added from the silo to the molten steel for vanadium alloying. After vanadium alloying, the circulation continues for 2 minutes, then the vacuum treatment is completed, the temperature is measured, and the molten steel is sent to the continuous casting process after sampling.

[0027] Among them, the amount of molten steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com