Bearing reaction restraining fixed structure of height crane gantry

A technology for fixing structures and supporting reaction force, which is applied in basic structure engineering, construction, etc., can solve problems such as the inability to guarantee the anchorage fastness, the overall stability of the portal frame cannot be ignored, and the steel pipe piles cannot reach the depth of the covering layer, etc., and achieve the goal of construction The process is simple and quick, less consumables, and the effect of increasing the anchorage length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

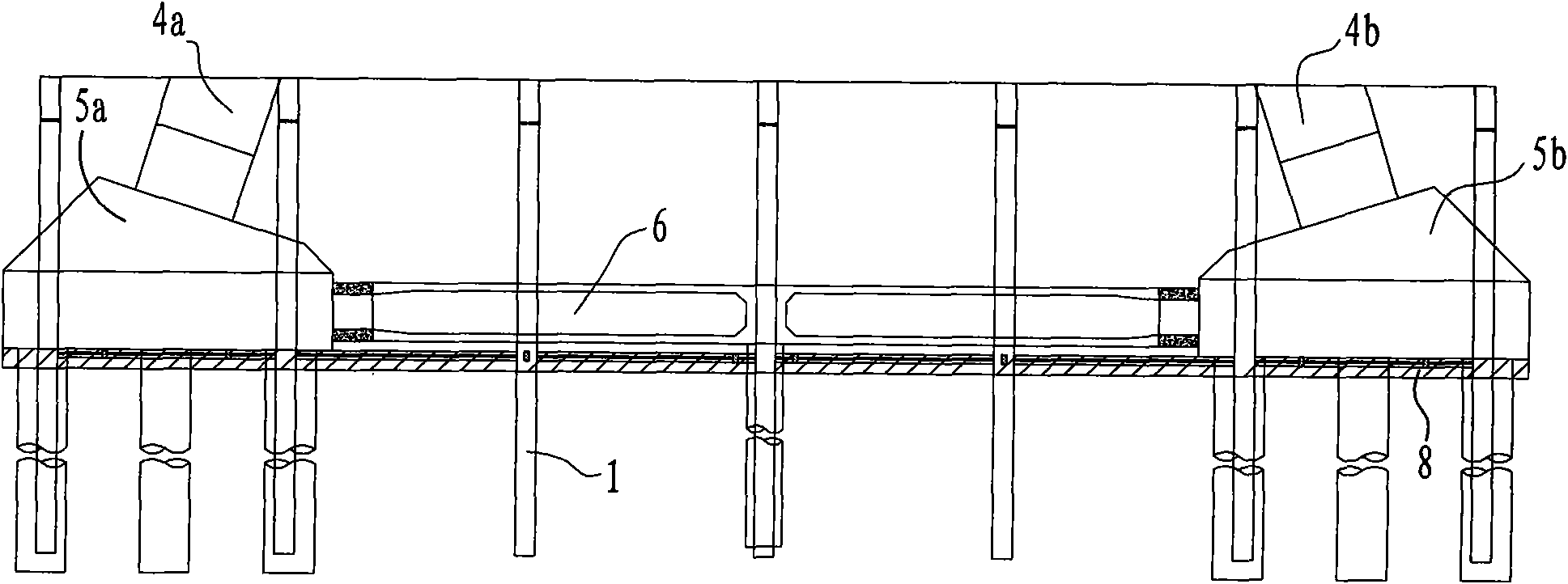

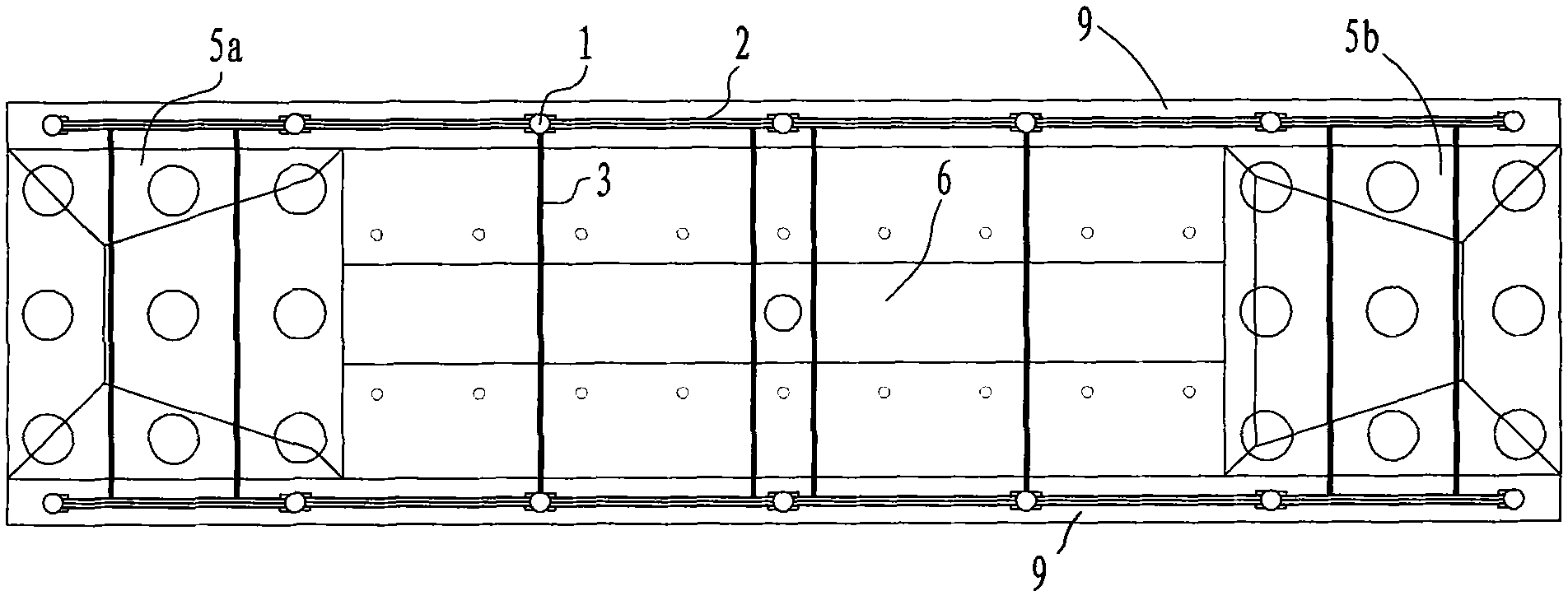

[0021] see figure 1 , figure 2 , in the present embodiment, in the cofferdam, at the location of each gantry steel pipe pile 1, a borehole deep to the rock surface is set, and each gantry steel pipe pile 1 supports the rock in the borehole by vibrating. On the surface; between the gantry steel pipe piles 1, the longitudinal section steel 2 and the transverse section steel 3 are respectively connected to form a bottom frame with the gantry steel pipe pile 1 as the opposite side, and the bottom frame is pre-buried in the bottom cover of the cofferdam In the concrete layer 8 , on the level of the back-sealing concrete layer 8 , on the periphery of each steel pipe pile 1 of the portal frame, two integral buttresses 9 of steel pipe piles on opposite sides are formed with poured concrete.

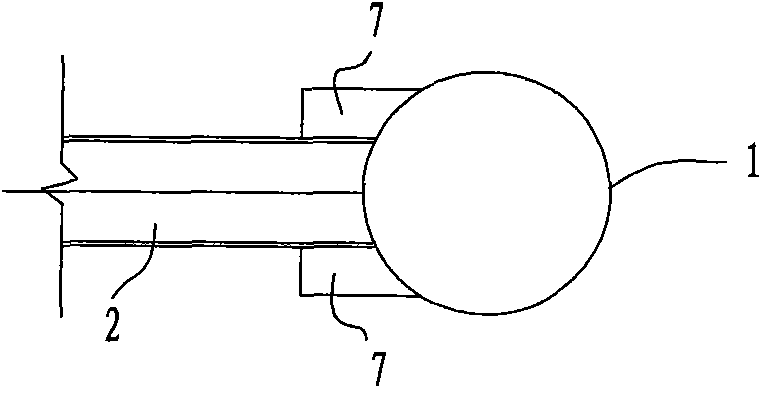

[0022] In the specific implementation, both the longitudinal section steel 2 and the transverse section steel 3 adopt "I"-shaped steel. In order to ensure the firm connection between the gantry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com