A bridge deck wet joint joint and its construction method and application

A construction method and wet joint technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as difficulty in welding and binding of lower steel bars, and impact on project progress, so as to reduce construction difficulty, improve bearing capacity, and avoid construction. effect of delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

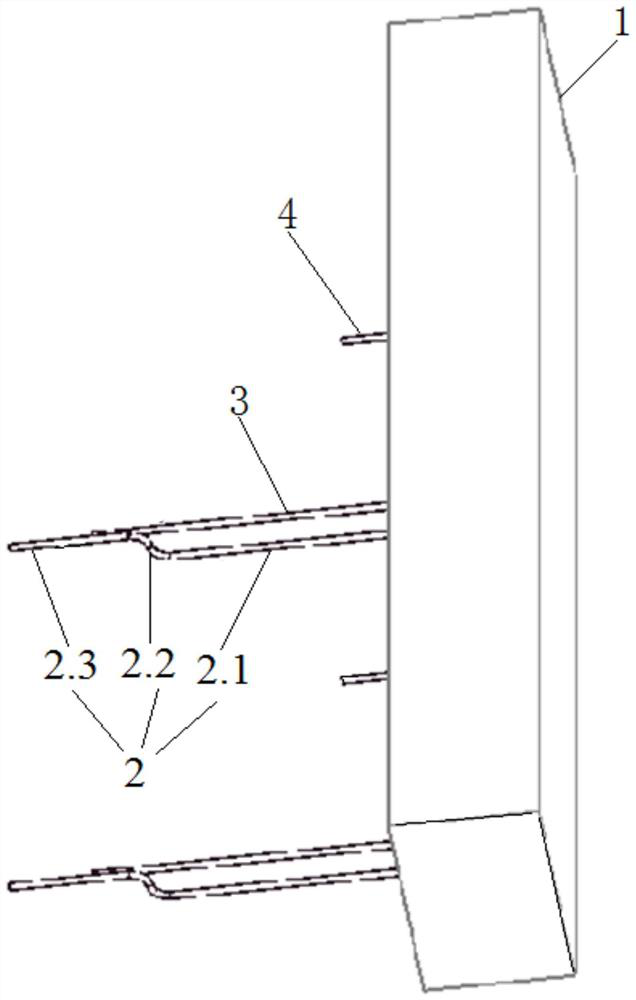

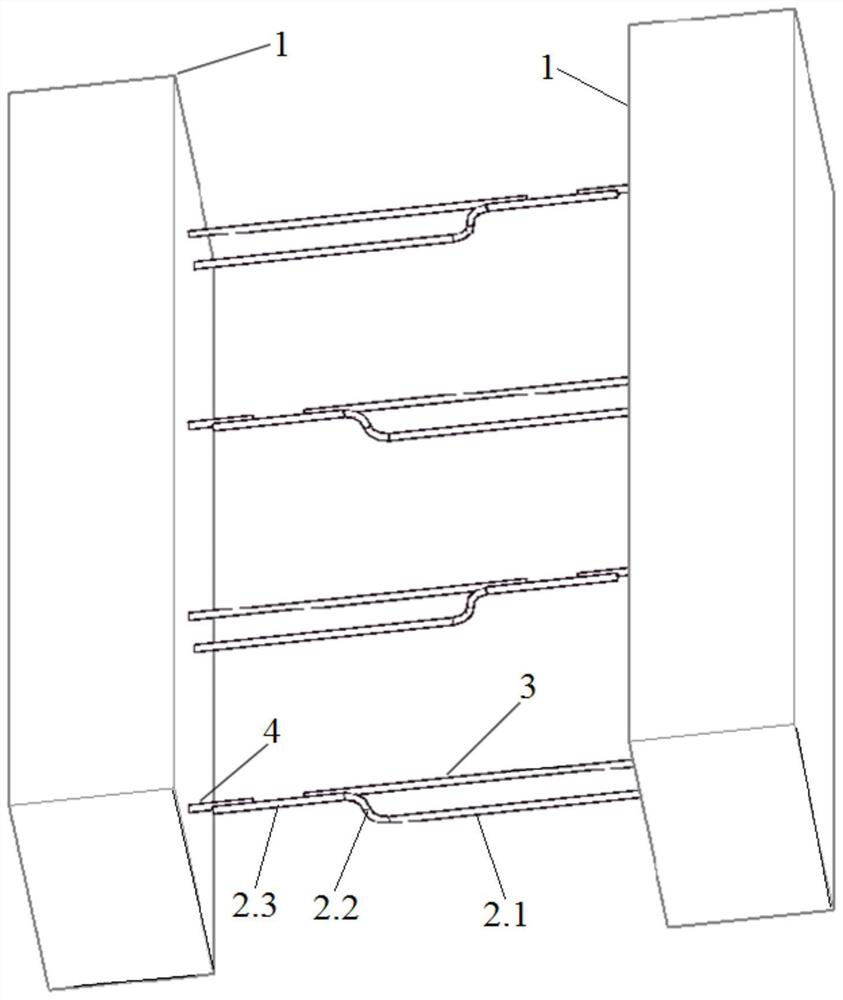

[0040] first embodiment ,refer to figure 1 , an example of a single-side bridge deck wet joint joint designed by the present invention, including: a prefabricated bridge deck 1, bent steel bars 2, long straight bars 3 and short straight bars 4.

[0041]The side walls of the prefabricated bridge deck 1 are fixed with curved steel bars 2, long straight steel bars 3, and short straight steel bars 4, wherein one end of each of the long straight steel bars 3 and short straight steel bars 4 is anchored in the prefabricated bridge deck 1 , and the long straight bars 3 and the short straight bars 4 are staggered along the length direction of the wet joint.

[0042] The bent steel bar 2 includes a lower straight steel bar section 2.1, a curved arc-shaped steel bar section 2.2, and an upper straight steel bar section 2.3. One end of the lower straight steel bar section 2.1 is fixed in the prefabricated bridge deck, and the curved arc The two ends of the shaped steel bar section 2.2 a...

no. 2 example

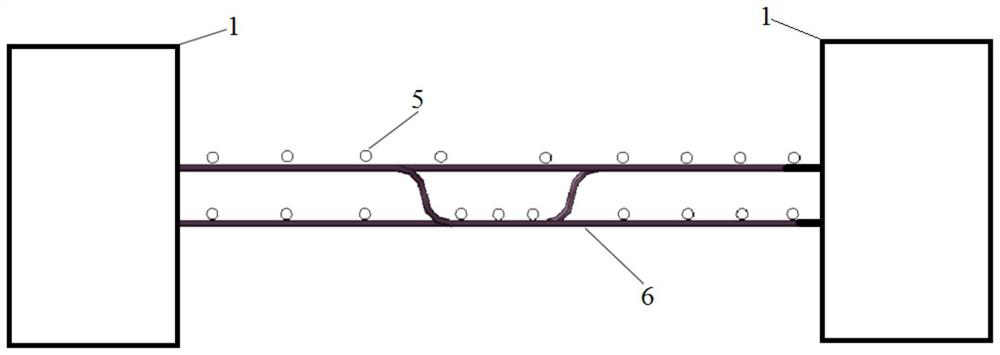

[0044] second embodiment , the bridge deck wet joint joint also includes two layers of longitudinal reinforcement 5, which are distributed along the length direction of the wet joint, wherein one layer of longitudinal reinforcement 5 is tied to the long straight reinforcement 3, the short straight reinforcement 4, and the upper straight reinforcement section 2.3 Together, another layer of longitudinal reinforcement 5 and the lower layer of straight reinforcement section 2.1 are tied together, so that the longitudinal reinforcement 5 and the wet joint joint of the bridge deck form a whole and jointly bear force.

no. 3 example

[0045] third embodiment , the bending line type of the curved arc-shaped steel bar section 2.2 is two semi-circular arcs with symmetrical center and equal radius, the arc radius R=H / 2, H is the long straight steel bar 3 and the lower straight steel bar Vertical straight-line distance between paragraphs 2.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com