Novel engine oil cooling system externally equipped with condenser at air inlet of air-cooled engine

An air-cooled engine and engine oil cooling technology, which is applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of engine oil temperature rise, small size, and reliability decline, and achieve reasonable structure, large cooling area, and cooling good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

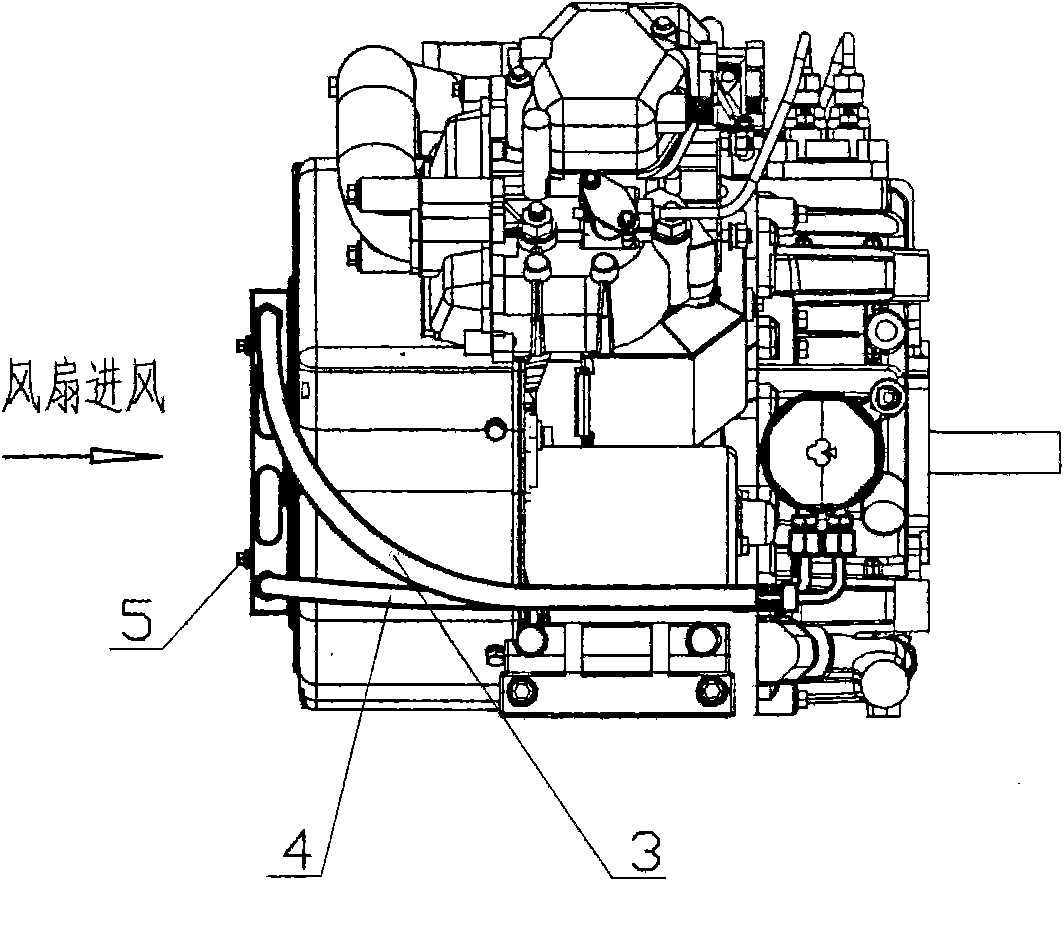

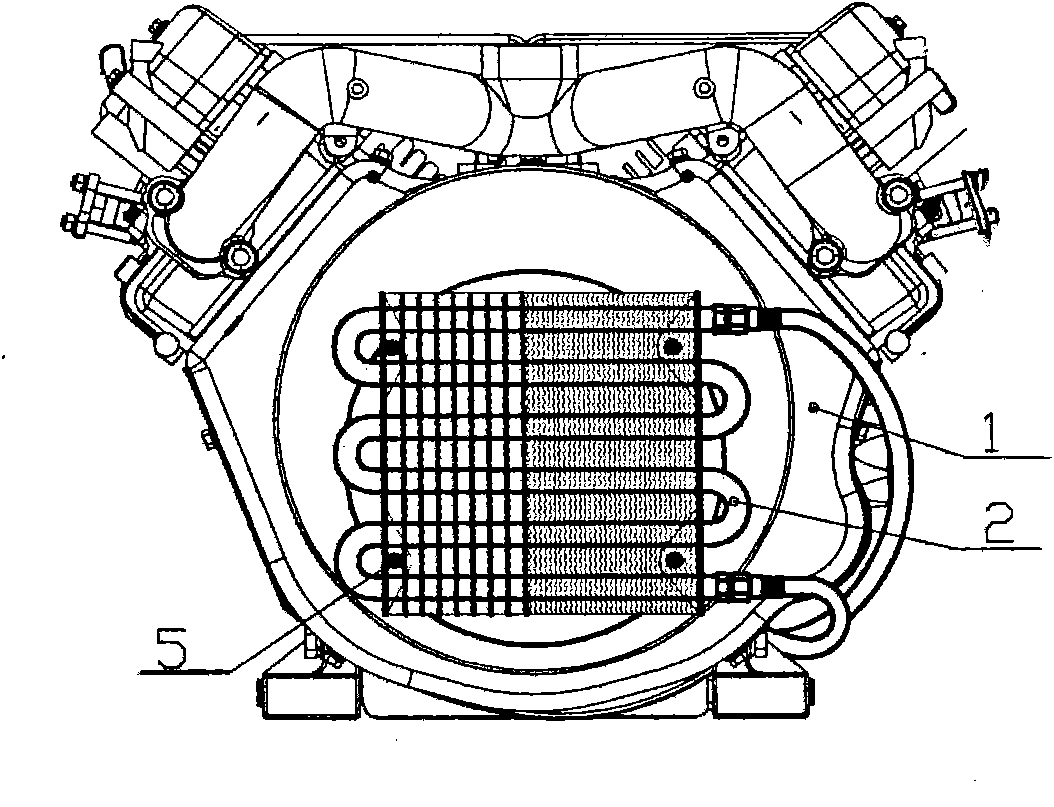

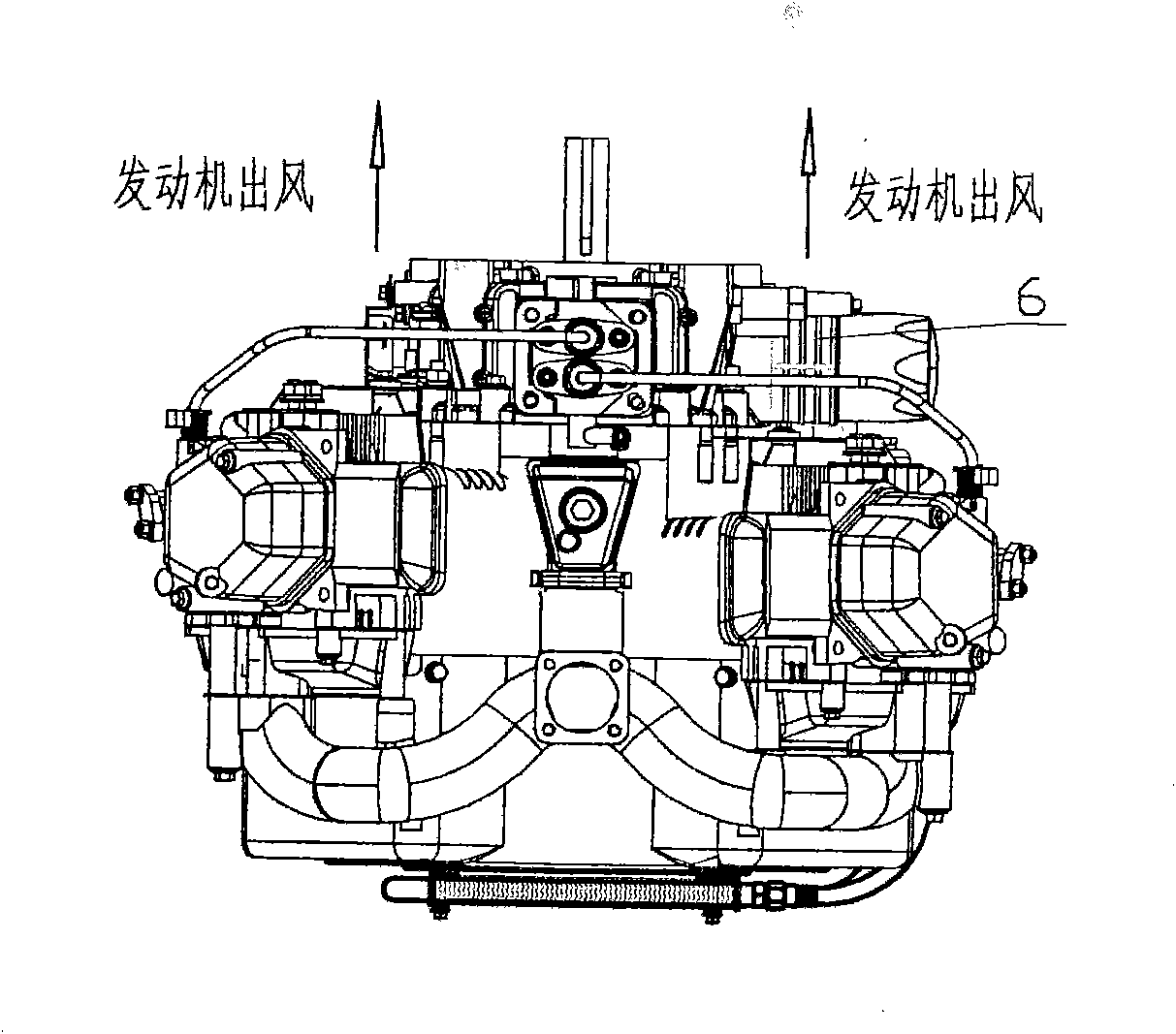

[0013] A new type of oil cooling system with an external condenser at the air inlet of an air-cooled engine, comprising an oil inlet pipe 4 and an oil outlet pipe 3; one end of the oil inlet pipe is connected to the oil outlet of the body chamber cover 6, and the other end of the oil inlet pipe Connected with the condenser; one end of the oil outlet pipe is connected with the oil inlet of the body cover, and the other end of the oil outlet pipe is connected with the condenser 2; the condenser is fixed on the air inlet of the engine air guide cover 1 by the fixing bolt 5 . There are cooling fins on the main oil passage of the condenser. The condenser is in the form of a serpentine tube or other suitable form.

[0014] When the engine is working, the internal engine oil enters the condenser 2 through the oil outlet of the chamber cover 6 and enters the condenser 2 through the oil inlet pipe 4 under the pressure of the engine oil pump. Cooling and heat exchanging are carried ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com