Pixel array structure

A pixel array and pixel technology, which is applied in the structural design of liquid crystal panels, can solve the problems of not being too close, loss of pixel aperture ratio, common voltage and gate line misconduction, etc., so as to avoid misconduction and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0020] As mentioned above, in the existing mesh-com design of the pixel array structure, the same pixel common voltage is used between two adjacent pixels, and the electrical conduction is performed through the via hole, the metal layer and the ITO conductive layer in sequence. However, the specific location of the via hole may often cause a significant loss in pixel aperture ratio, because the distance between the via hole and the gate line of the pixel can neither be too large nor too small. Furthermore, if the distance between the two is too large, the aperture ratio of the pixel will be reduced, and if the distance is too small, false conduction between the via hole and the gate line will occur.

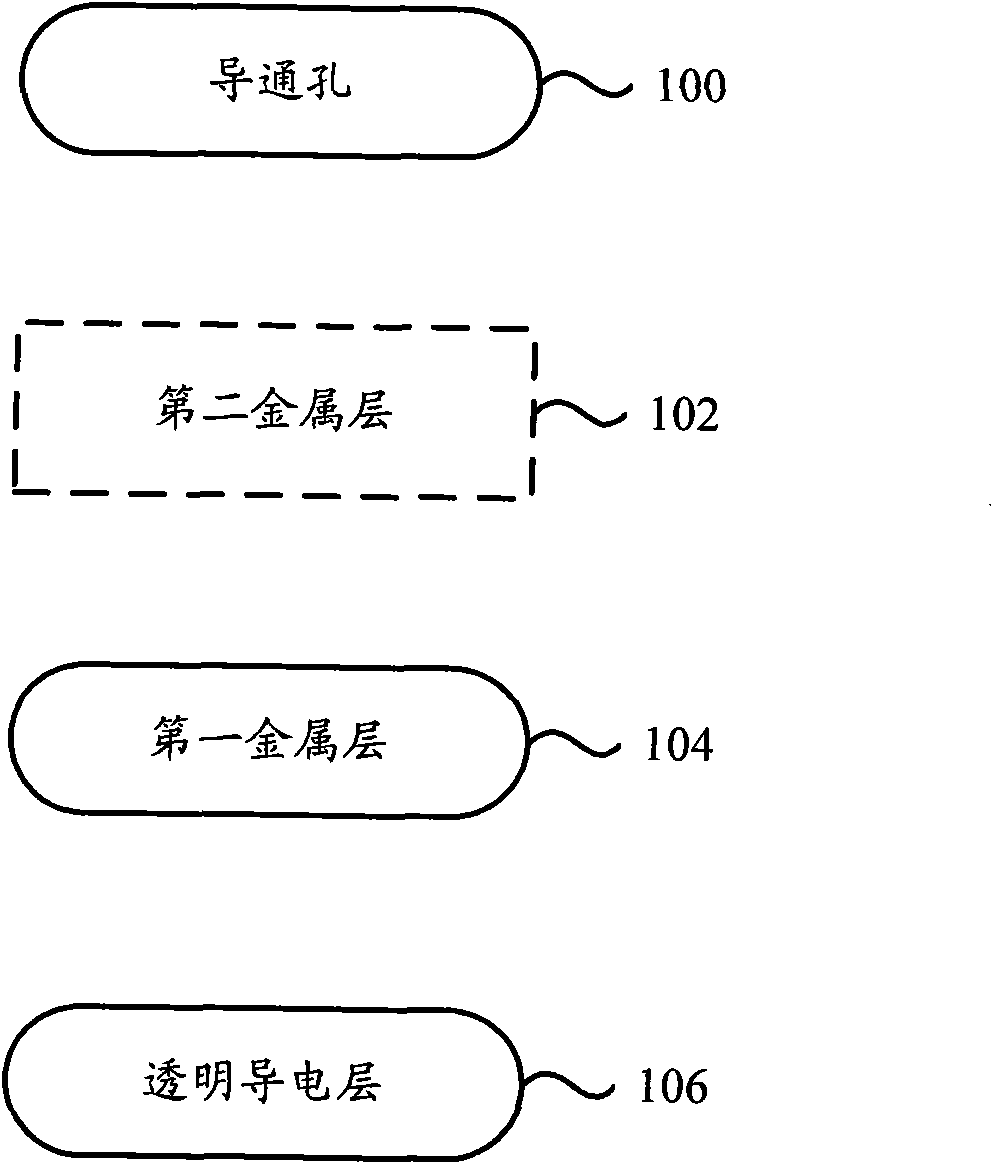

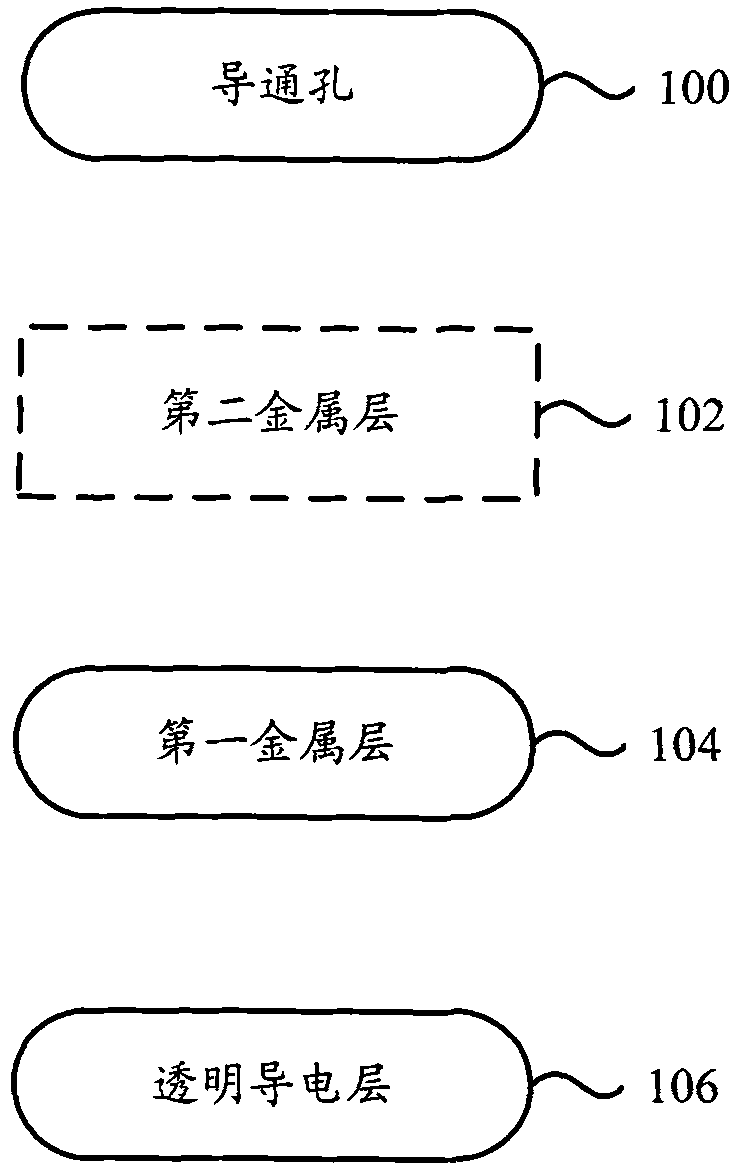

[0021] In order to solve this problem, the present invention provides a new pixel array structure. figure 1 According to a preferred embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com