Caulking coupling device, switch and transmission switch

A connecting device and riveting technology, applied in the direction of transmission control, forging/pressing/hammer device, connection, etc., can solve the problems of weakening the riveting connection force, weakening the riveting connection force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

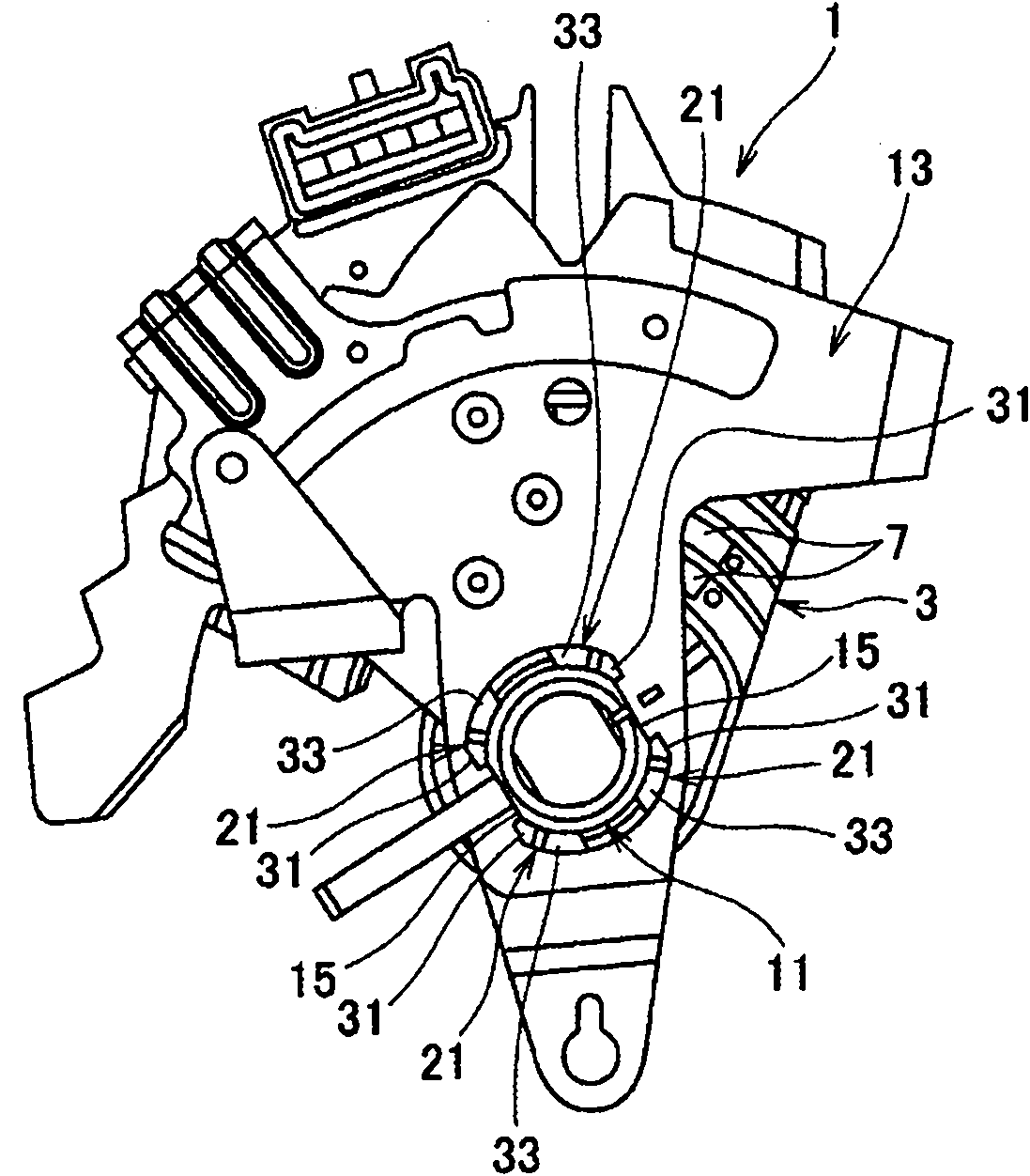

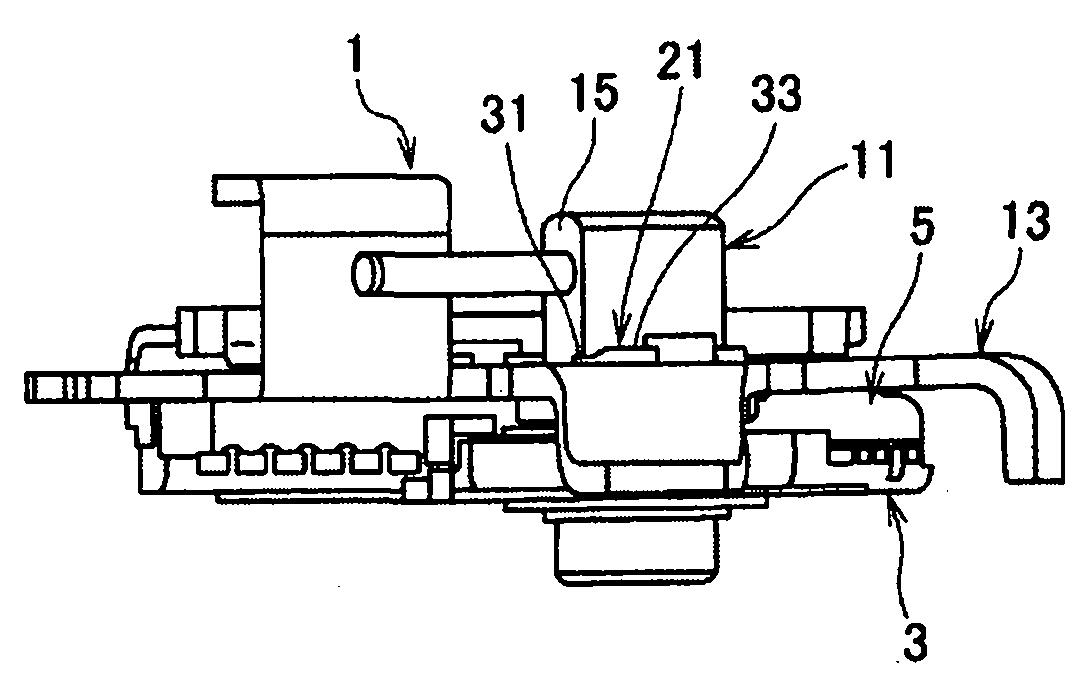

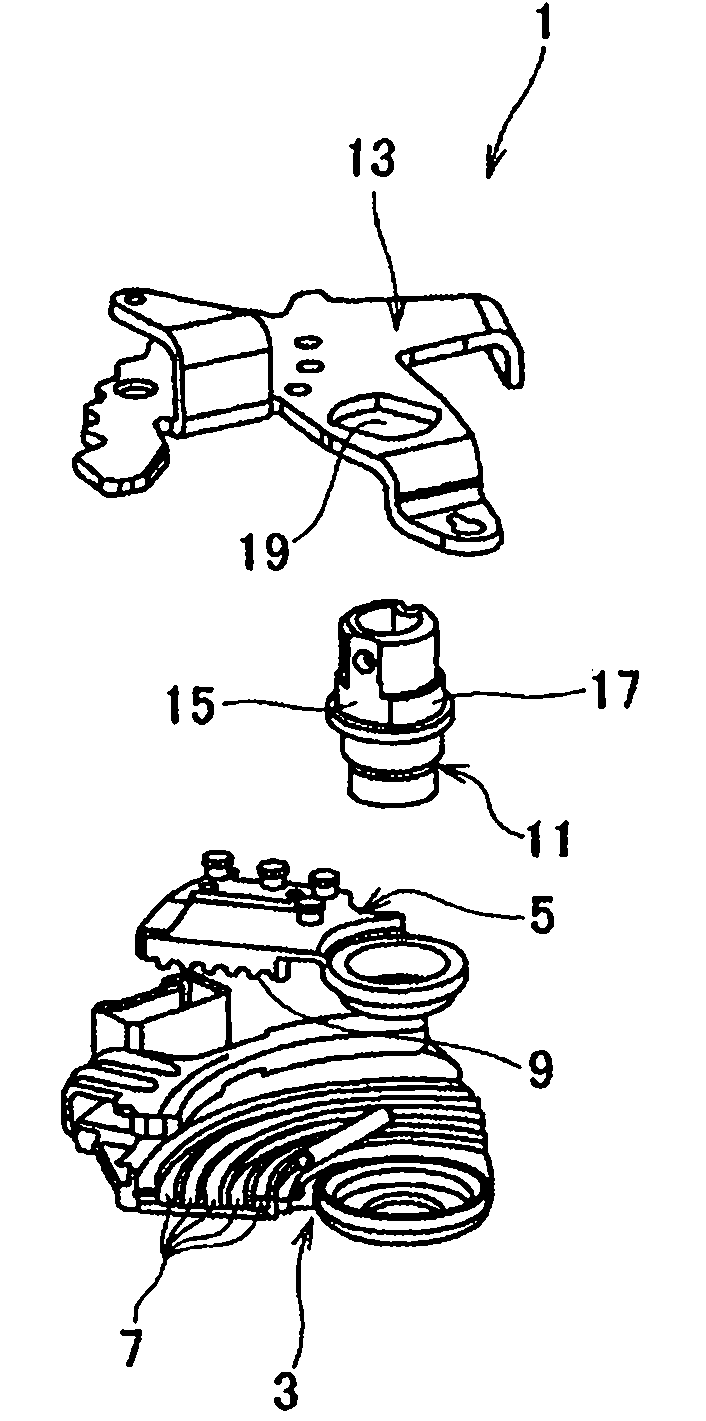

[0077] figure 1 FIG. 3 shows a first embodiment of the invention. figure 1 is a plan view showing the transmission switch. figure 2 is its side view. Figure 3A is an exploded perspective view showing the state before the column member and the stopper plate are assembled. Figure 3B is an exploded perspective view showing a state after assembly. Figure 3C is an exploded perspective view showing a state after riveting coupling of the column member and the stopper plate.

[0078] figure 1 The basic structure of the transmission switch 1 shown in Figure 3 is similar to Figure 8 to Figure 1 0 shown in the transmission switch 101 and the difference lies in the structure of the riveted part. Accordingly, in figure 1 to the transmission switch 1 shown in Figure 3, using the Figure 8 to Figure 1 The code references obtained by subtracting the number 100 from the code in 0 are the same as Figure 8 to Figure 1 The components are the same as those in the transmission sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com