Novel cylindrical electromagnetic drive equipment

An electromagnetic drive and equipment technology, applied in the field of new-type drum electromagnetic drive equipment, can solve the problems of increased smoothness of the contact surface between the roller and the groove of the mold, high noise, and wear of the roller and the groove of the mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

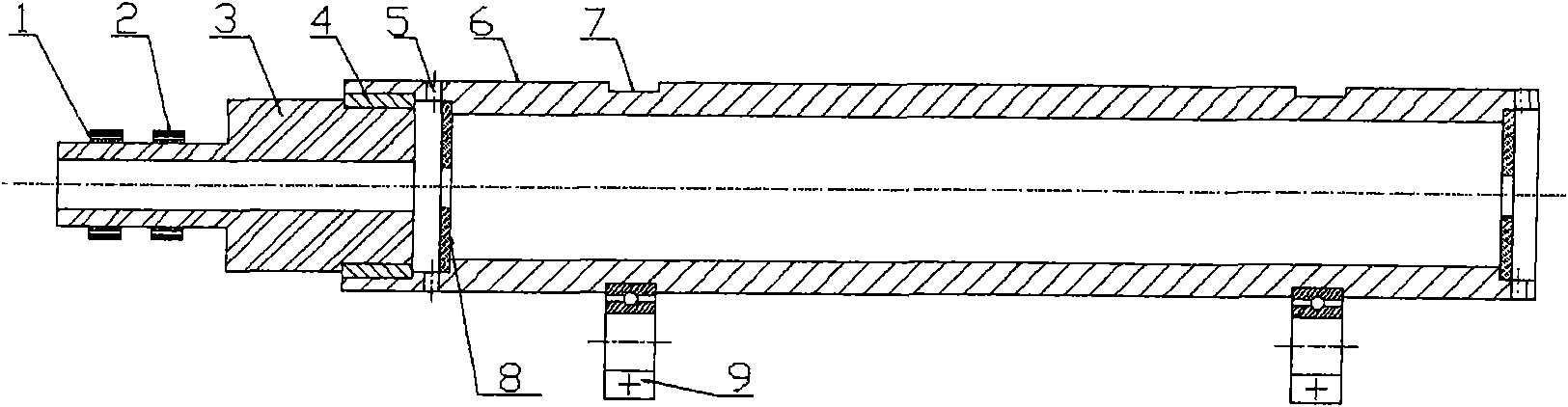

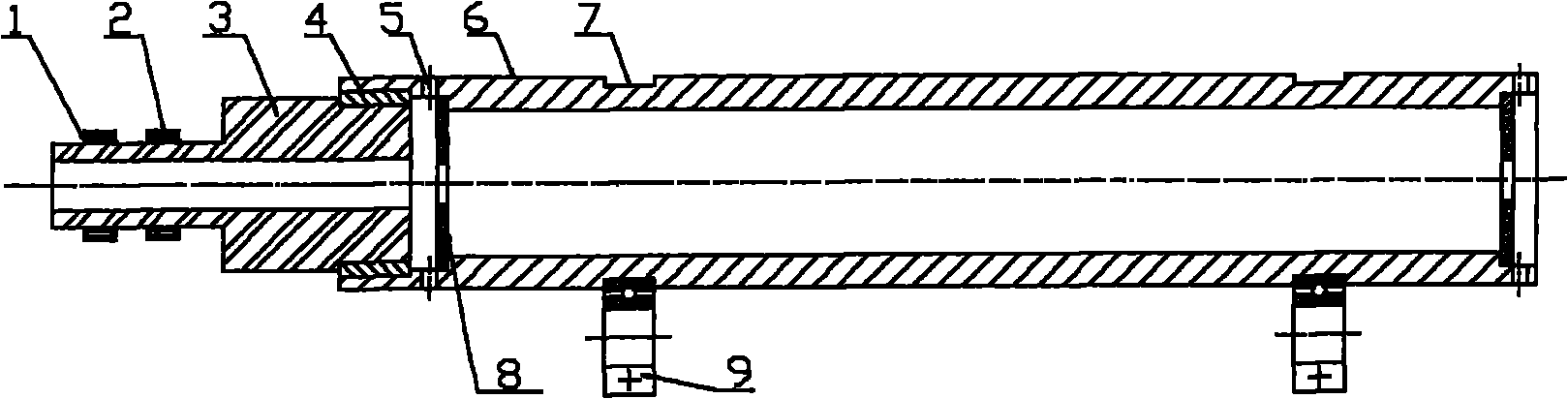

[0007] A new type of cylinder electromagnetic drive equipment, mainly composed of a metal mold cylinder 6, the metal mold cylinder 6 is provided with a linkage pin 4, an end cover fixing pin hole 5, and an end cover 8 is provided through the end cover fixing pin hole, and the metal mold cylinder The supporting bearing 9 corresponding to the size is placed in the original roller groove of the tube, and the bearing groove 7 is also provided on the molded tube. A driving shaft 3 is arranged outside the metal molded cylinder 6 , and a magnetic coil winding 1 is arranged on the driving shaft 3 , and each group of magnetic coils corresponds to the outer magnetic steel 2 .

[0008] The following is an analysis of the production and operation of the new type drum electromagnetic drive equipment:

[0009] Modification of the cold end of the type 1 cylinder

[0010] like figure 1 As shown, the cold end cover of the type cylinder is modified as follows:

[0011] (1) Properly extend th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com