Preparation method of bicycle wheel rim

A technology for bicycles and rims is applied in the field of making rims by using composite materials containing carbon fibers, which can solve the problems of poor structural strength, difficult demoulding of the rims, and adverse effects on the structural strength of the rims.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

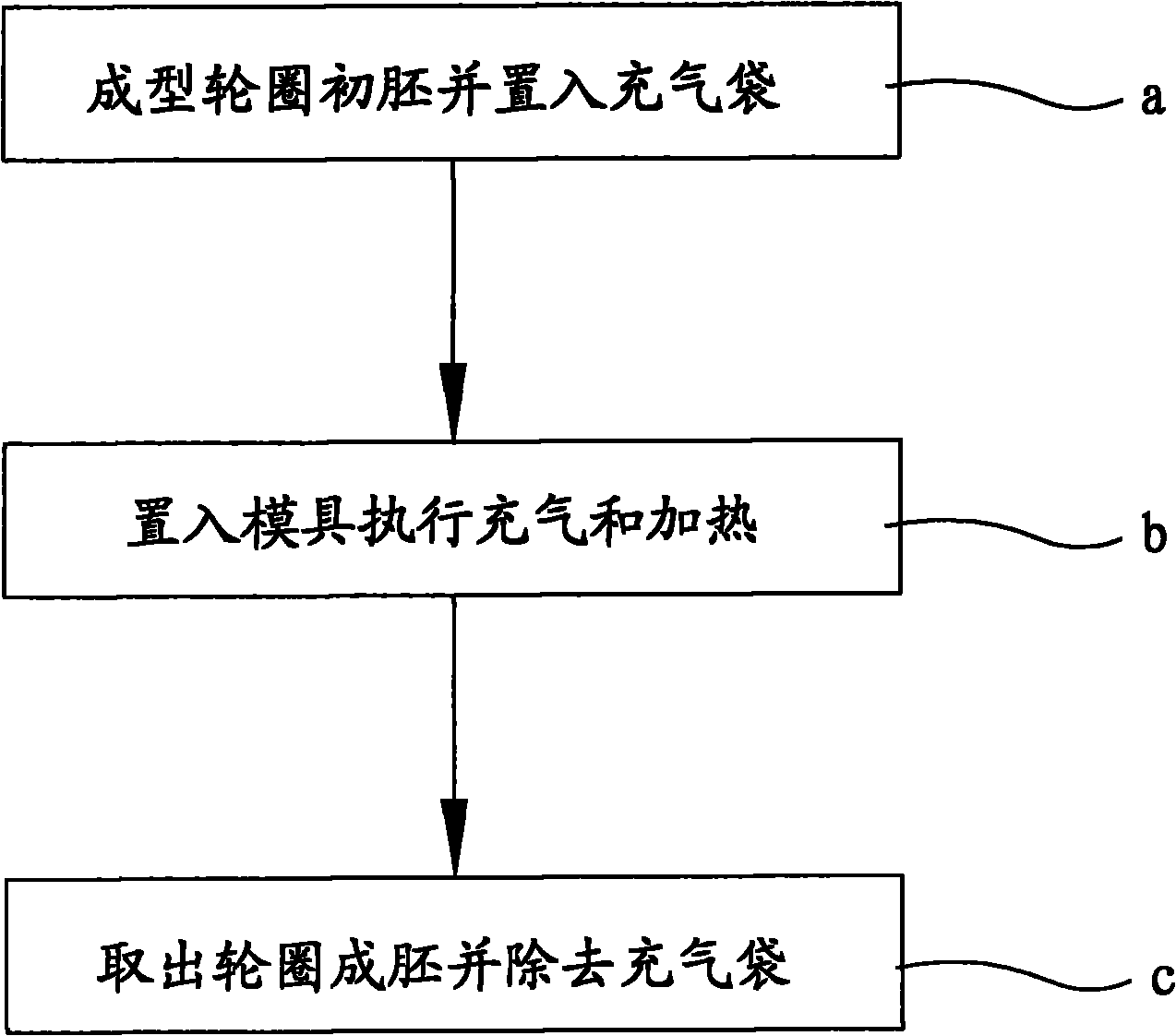

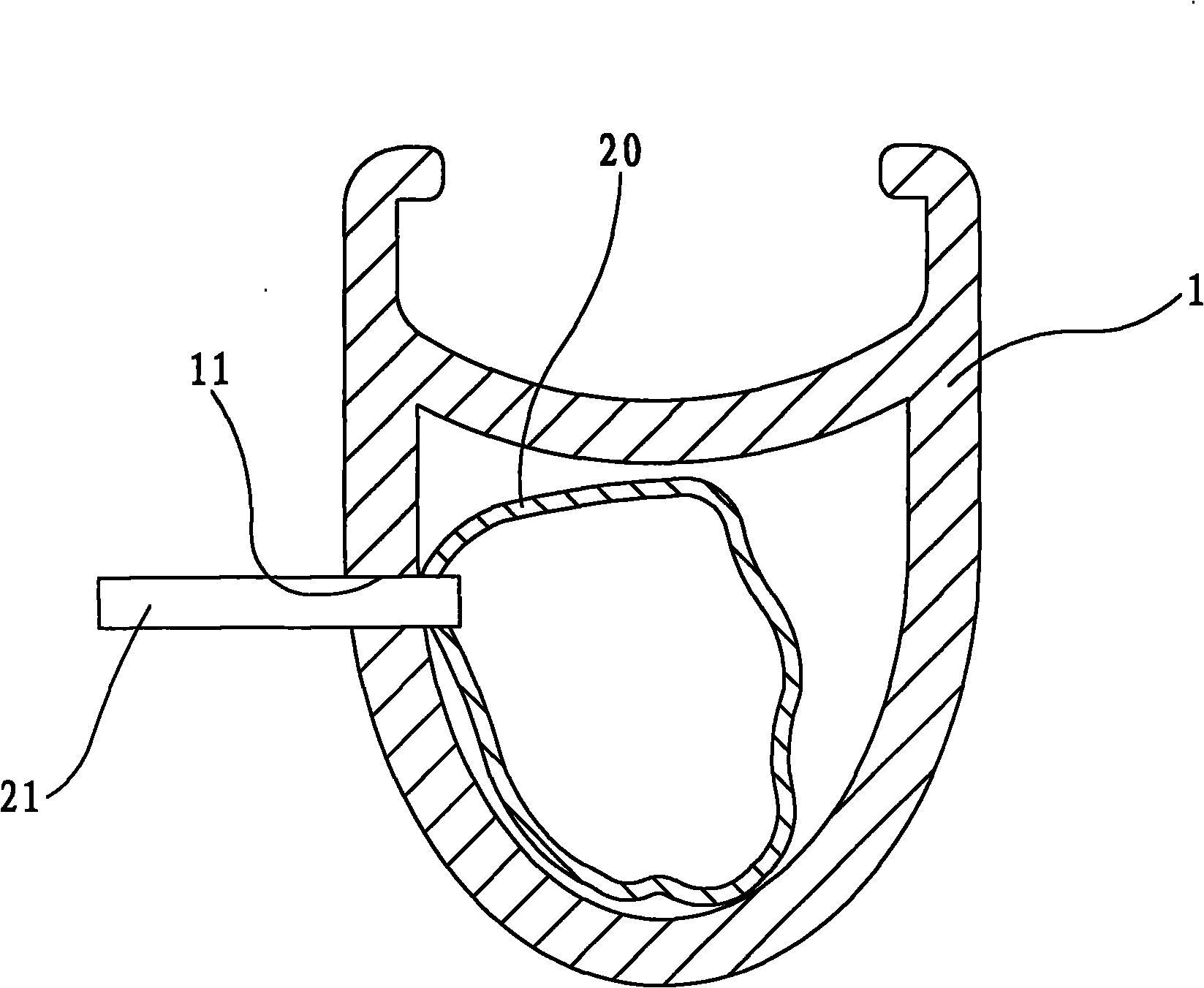

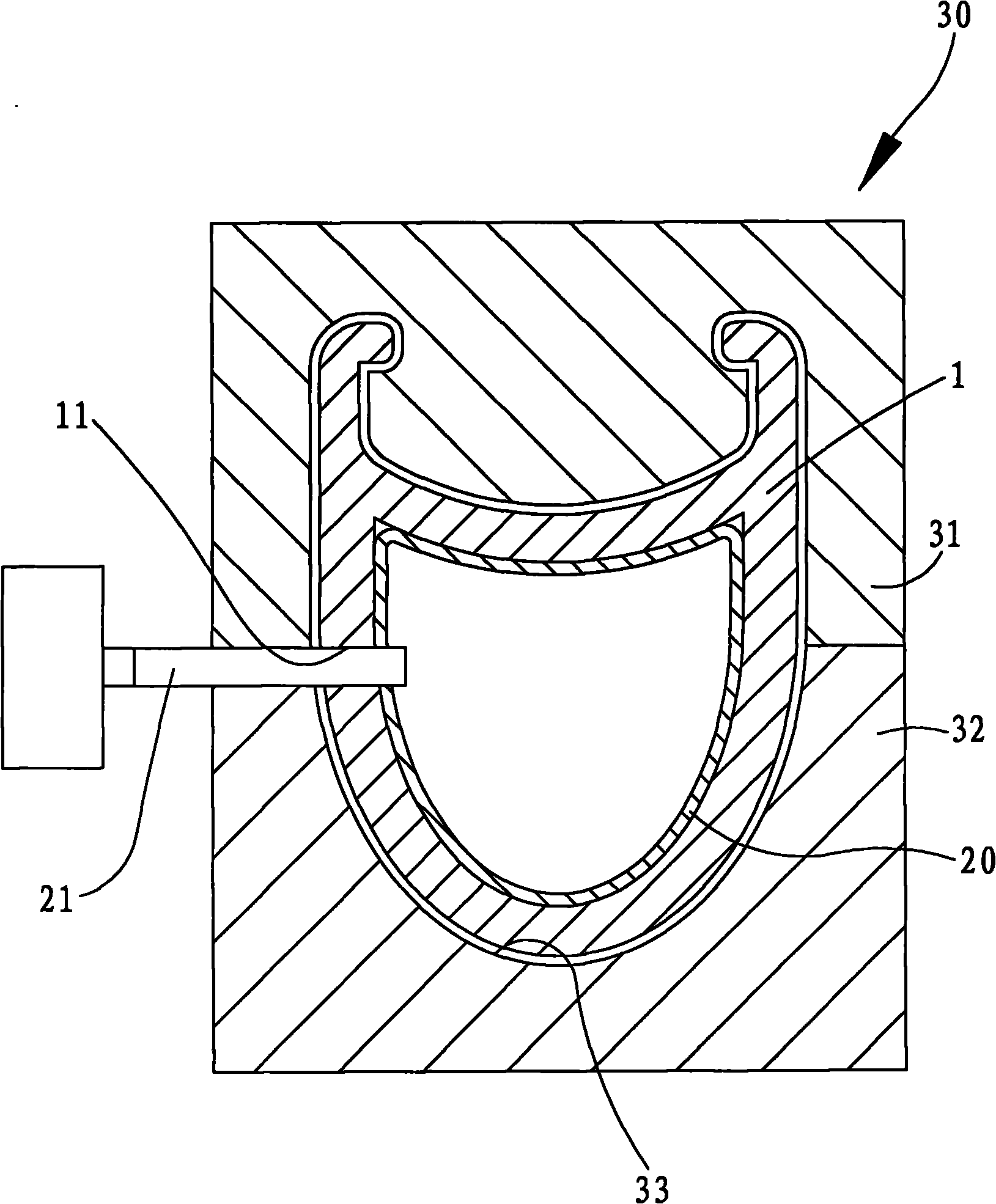

[0049] Such as Figure 5 As shown, a rim is produced through the following process: step a, forming a rim preform and placing it into an air bag; step b, placing it in a mold and forming it in the accommodation space surrounded by the rim preform and two supporting parts There is a mandrel; step c, perform the inflation and heating procedure; step d, take out the rim molding and remove the inflation bag or mandrel.

[0050] Such as Image 6 , 7 As shown, the mold 30 of this embodiment is still formed by merging upper and lower molds 31 and 32, and a mold cavity 33 is formed inside the mold 30, allowing the rim preform 10 and a core mold 50 to be inserted. The mandrel 50 is molded in the accommodating space 40 surrounded by the rim preform 10 and the two supporting parts 12, and the heat shrinkable material 52 in the form of powder, chips or granules is transported to the long tube made of refractory material. In the strip air bag 51. The heat-shrinkable material 52 of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com