motorcycle tire

A technology of motorcycle tires and tires, which is applied to motorcycle tires, motorcycles, tire parts, etc., and can solve the problems of reduced riding comfort, reduced ground contact area, and reduced straight-line driving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

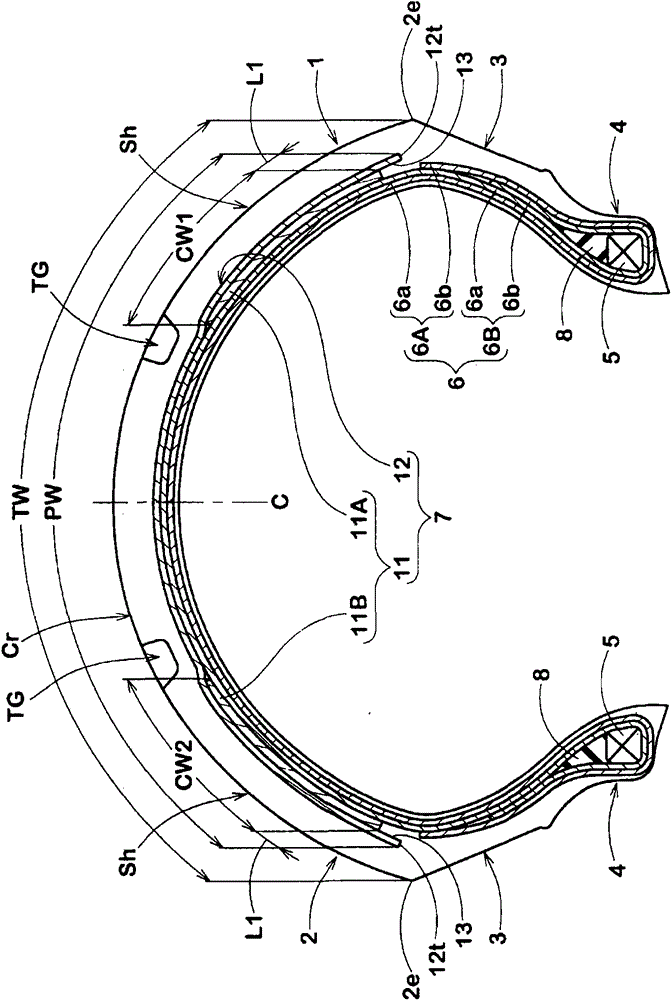

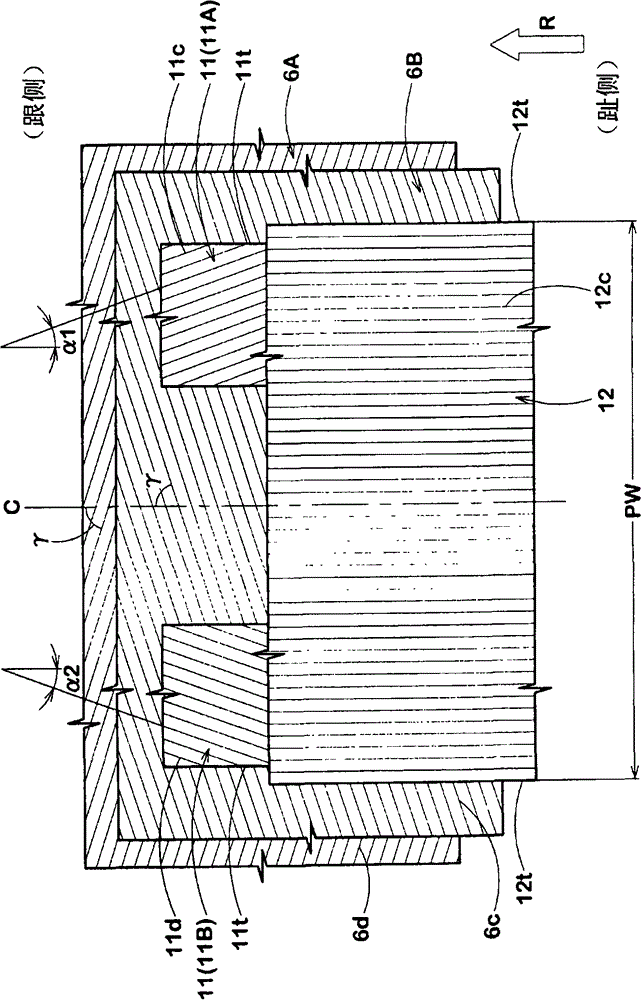

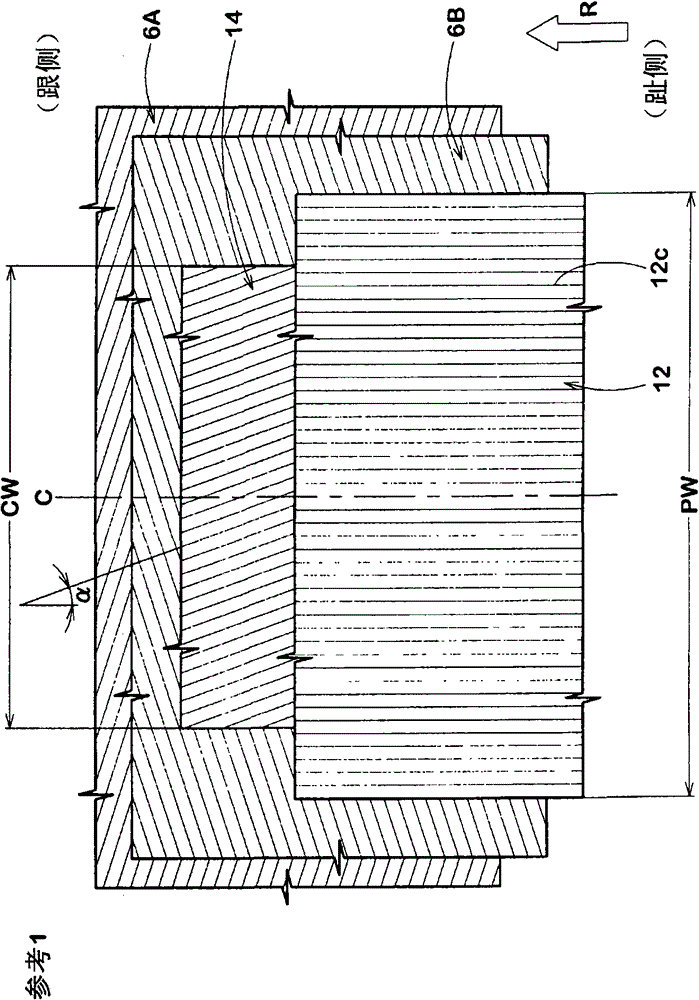

[0017] Embodiments of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0018] According to the present invention, a motorcycle tire 1 comprises a tread portion 2, a pair of axially spaced bead portions 4 each having a bead core 5 therein, a pair of bead portions 4 extending between the tread edge 2e and the bead portion 4. The sidewall portion 3 , the carcass 6 extending between the bead portions 4 , and the tread reinforcing layer 7 in the tread portion 2 provided outside the carcass 6 in the radial direction.

[0019] When compared with passenger car tires, truck / bus tires, etc., motorcycle tires are characterized in that their tread portion 2 (including the carcass 6, tread reinforcement 7 and tread rubber thereon) is formed with a relatively small curvature The radius is curved, so that the maximum section width of the tire is between the tread edges 2e.

[0020] The tread portion 2 has tread grooves TG forming a unidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com