Elevator car wall panels spliced by using slide slots and buckles

A technology for elevator cars and wall panels, which is applied to elevators, transportation, and packaging in buildings. It can solve problems such as troublesome installation and matching, and difficulty in installing car wall panels, so as to achieve reasonable and convenient manufacturing and installation, and save energy. Fastening of bolts and nuts, saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation of the elevator car wall panel spliced with chute and buckle according to the present invention will be given below in conjunction with the accompanying drawings, but the implementation of the present invention is not limited to the following implementation.

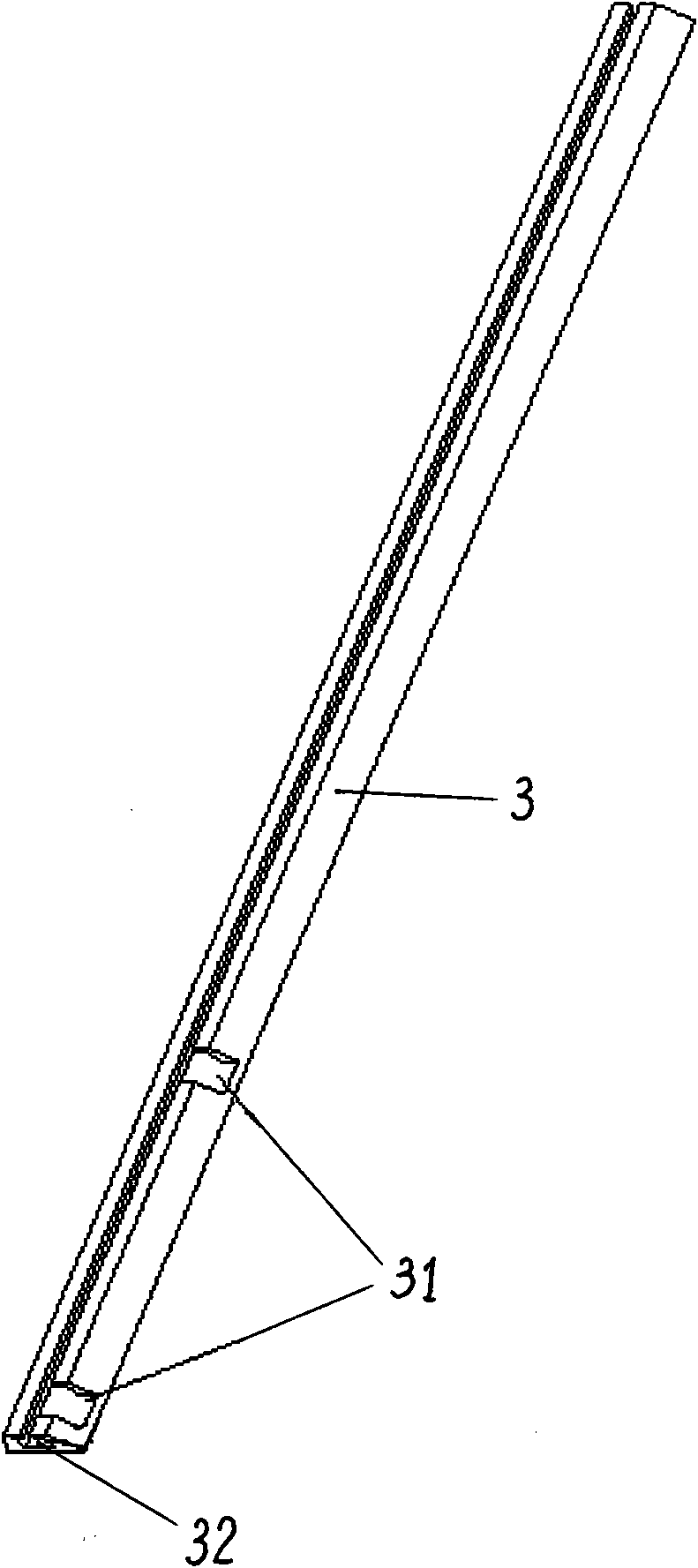

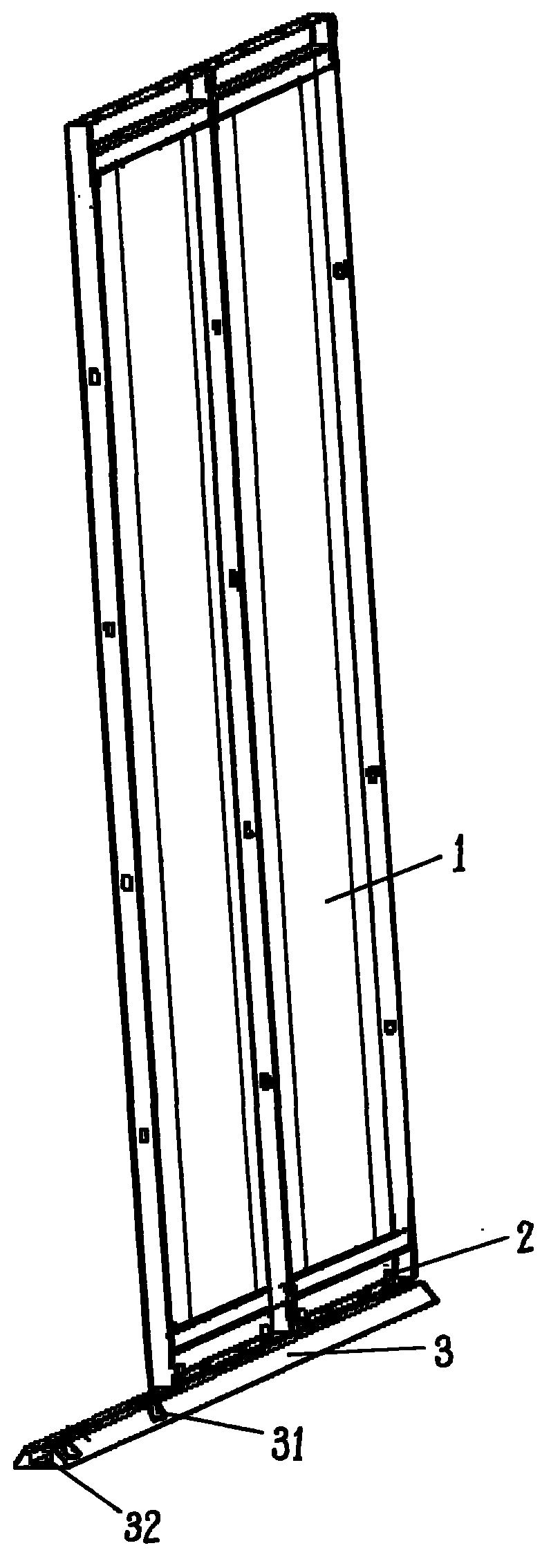

[0037] See attached Image 6 .

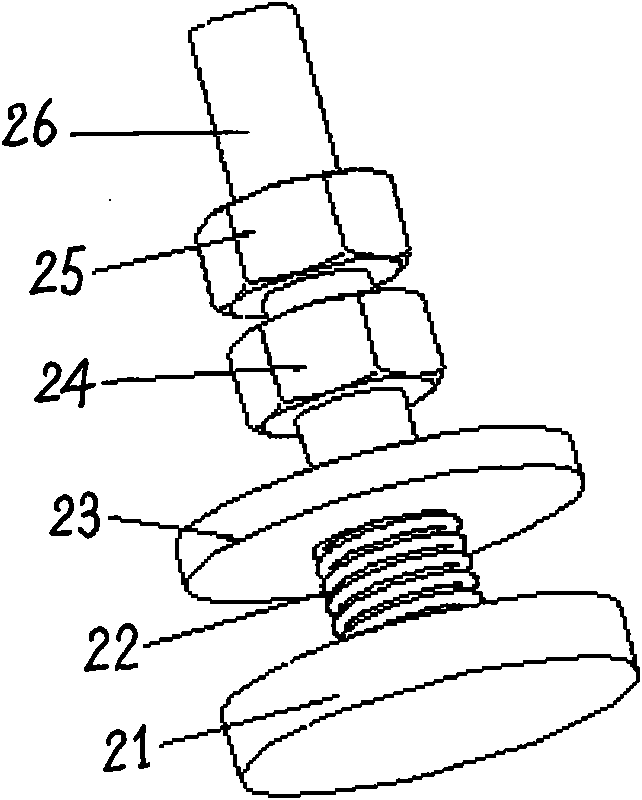

[0038] An elevator car wall plate spliced with chute and buckle, comprising a car wall plate 1 and a chute structure 3 . The main structure of the car wall plate 1 is the same as that of the existing car wall plate 1, but more than two buckles 11 are set on one side of the car wall plate 1, and more than two openings 12 are set on the other side (see attached figure 2 ), the buckle 11 and the opening 12 are matching buckle structures, corresponding one by one; A slide block 2 is arranged at the bottom end of the car wall plate 1 . Slide block 2 is made of screw rod 26, slide plate 21, spring 22, pressing plate 23 and fastening nut. Figure 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com