Method and device for monitoring and processing tail gas of excavators

A technology for excavators and exhaust gas, which is applied to the electronic control of exhaust treatment devices, exhaust treatment, exhaust devices, etc. The problem of particle secondary pollution and other problems, achieve the effect of simple structure, intuitive display and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

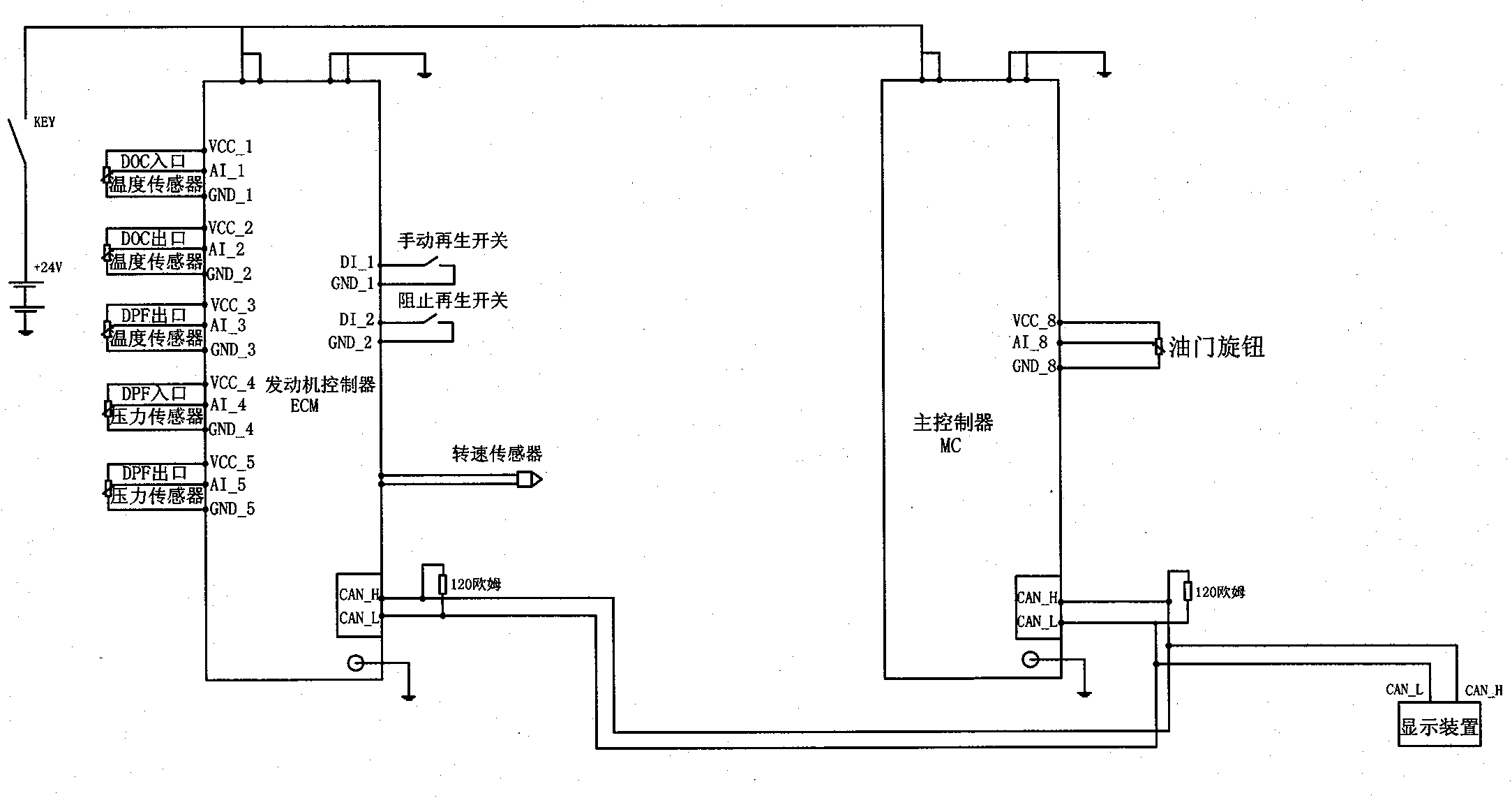

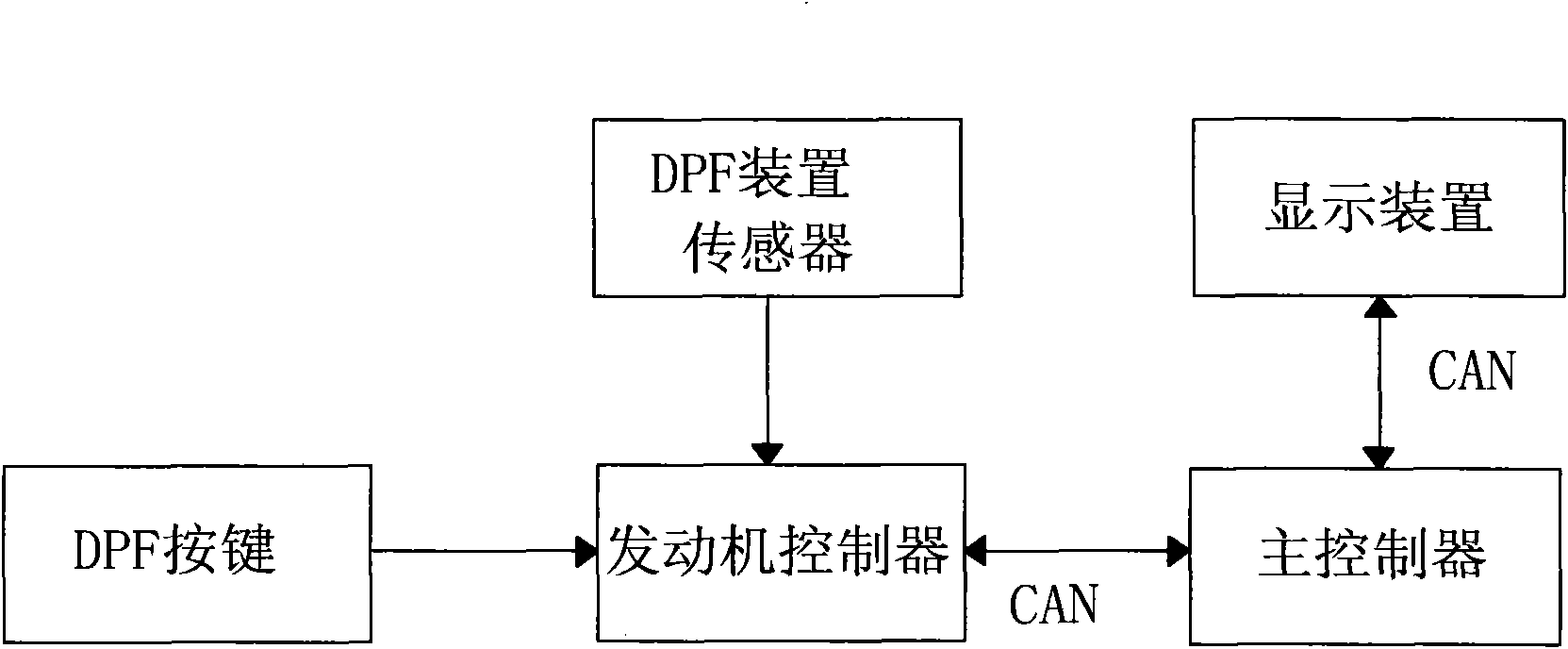

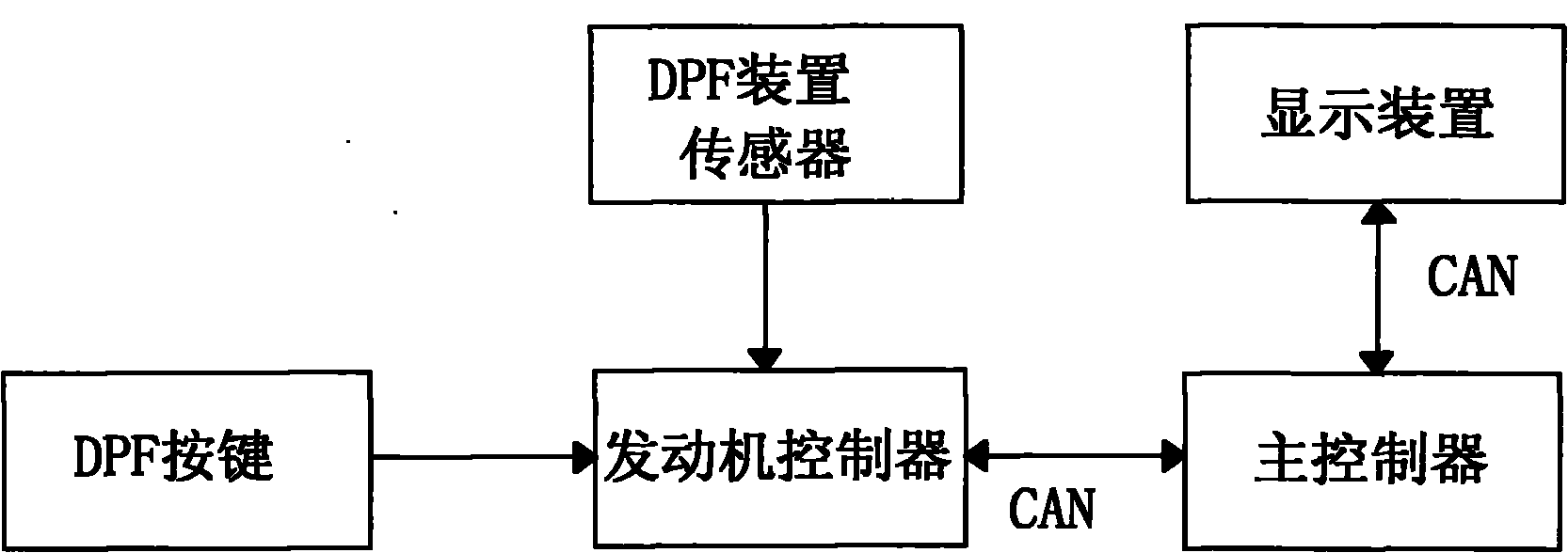

[0017] Embodiment one: see figure 1 , 2 As shown, an exhaust gas monitoring and processing method for excavators, the information collected by the sensor in the particulate filter is transmitted to the main controller through the engine controller, the main controller receives the information and transmits it to the display device, and the presetting step is performed first , set the start pressure and end pressure of the regeneration control through the detection of the excavator; when the engine controller detects that the pressure difference between the inlet and outlet of the particulate filter is greater than the set start pressure, and the temperature of the particulate filter is not lower than Automatic regeneration is performed at 250°C, the engine controller increases the engine temperature to keep the particle filter in the state of automatic regeneration, when the pressure difference between the inlet and outlet of the particle filter is less than the set end pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com