Layer combustion boiler for combusting bundled straw

A straw and boiler technology, applied in the field of layer-fired boilers, can solve tar pollution, affect the long-term stable and safe operation of the system, and pollute the heating surface of the flow, so as to reduce the combustible carbon content of slag discharge, increase the temperature, and improve the efficiency of the boiler.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

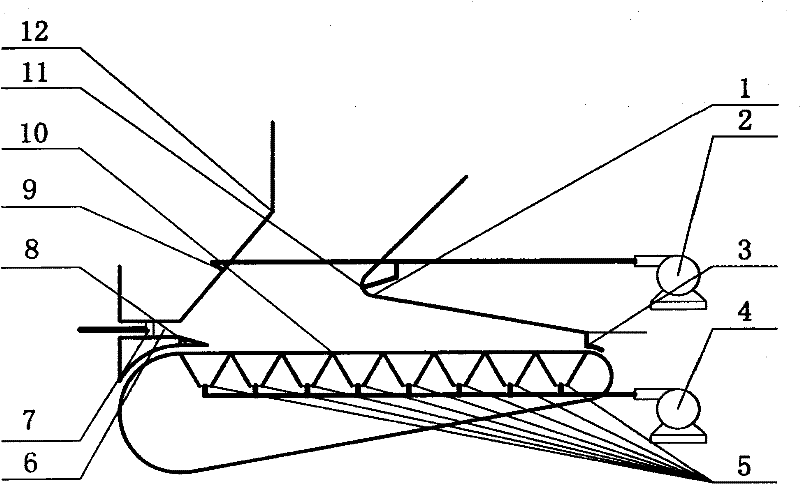

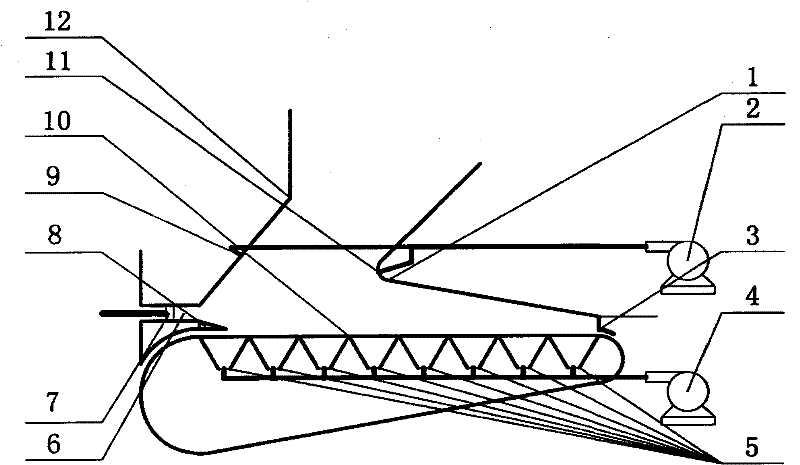

[0024] The present invention provides a stratified-fired boiler that burns bundles of straw. The stratified-fired boiler includes a feed mechanism, a combustion chamber, and an air supply mechanism. The feed mechanism can be realized by adopting various structures in the prior art, such as The motor-driven screw feeding mechanism, etc., are not restricted in this case; the combustion chamber of the present invention is provided with a front arch and a rear arch, and a feed port is provided under the front arch, and the feed mechanism will be used to form a material through the feed port. The straw bales are pushed into the combustion chamber. The lower part of the combustion chamber is provided with a chain grate. The lower part of the back arch is provided with a slag baffle at the end of the chain grate; the air supply mechanism includes a primary air supply mechanism and a secondary air supply. The primary air supply mechanism includes a primary fan and a primary air chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com