Self-sealed drainer of pipe bundle drier

A tube bundle drying and drainer technology is applied in the field of mechanical equipment, which can solve the problems of reducing the discharge of condensed water, increasing the consumption of steam, and reducing the efficiency of steam use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

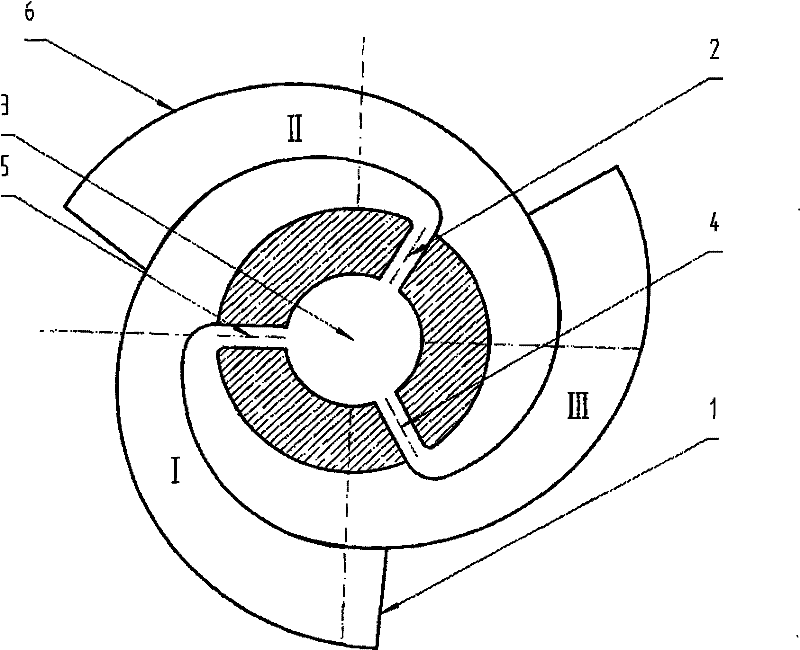

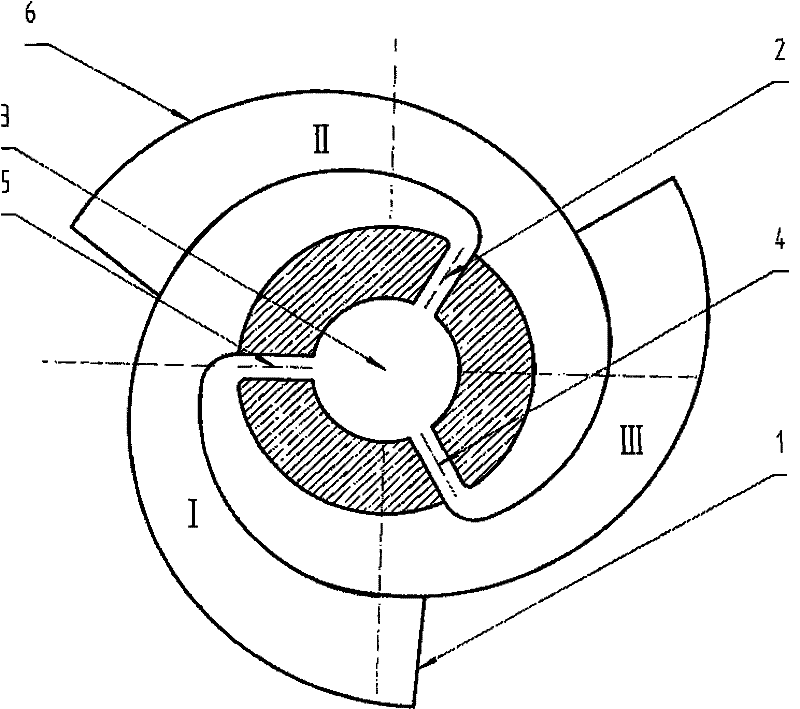

[0010] A self-sealing drain for a tube bundle dryer. With reference to the drawings, it includes a hollow half shaft 3 placed in the head of the outlet end. There is no partition in the hollow half shaft 3, and there are several condensation on the hollow half shaft 3 The water drainage holes 2, 4, 5, along the outer circle of the hollow half shaft 3, lead out a gradual opening condensate deflector 6 at each condensate drain hole, and the gradual opening condensate deflector 6 is welded on On the inner wall of the head, drainage grooves I, II, and III are formed between the involute condensate deflector 6 and the outer circle of the hollow half shaft 3, and a cover plate is welded on the drainage groove.

[0011] There are three involute drains (I, II, and III) in this scheme. When the water inlet 1 of the drain (I) rotates to the lowest position with the hollow half shaft 3, the condensed water is picked up and the condensed water enters Drainer I cavity, the hollow half shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com