Section drying cut tobacco equipment and method

A technology of segmental drying and shredded leaves, applied in the direction of tobacco preparation, application, tobacco, etc., to achieve the effect of improving the efficiency of rapid dehydration and drying, increasing the filling capacity, and maintaining the inherent aroma and style characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

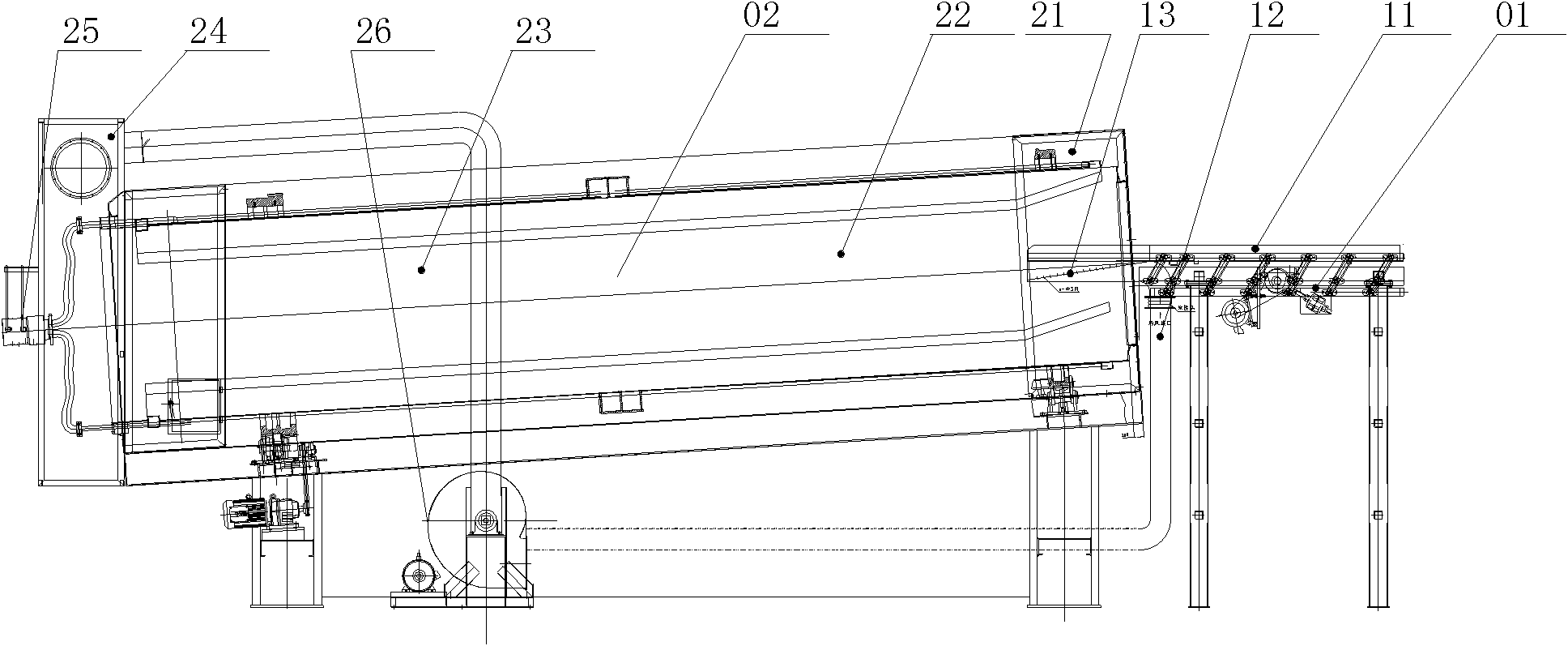

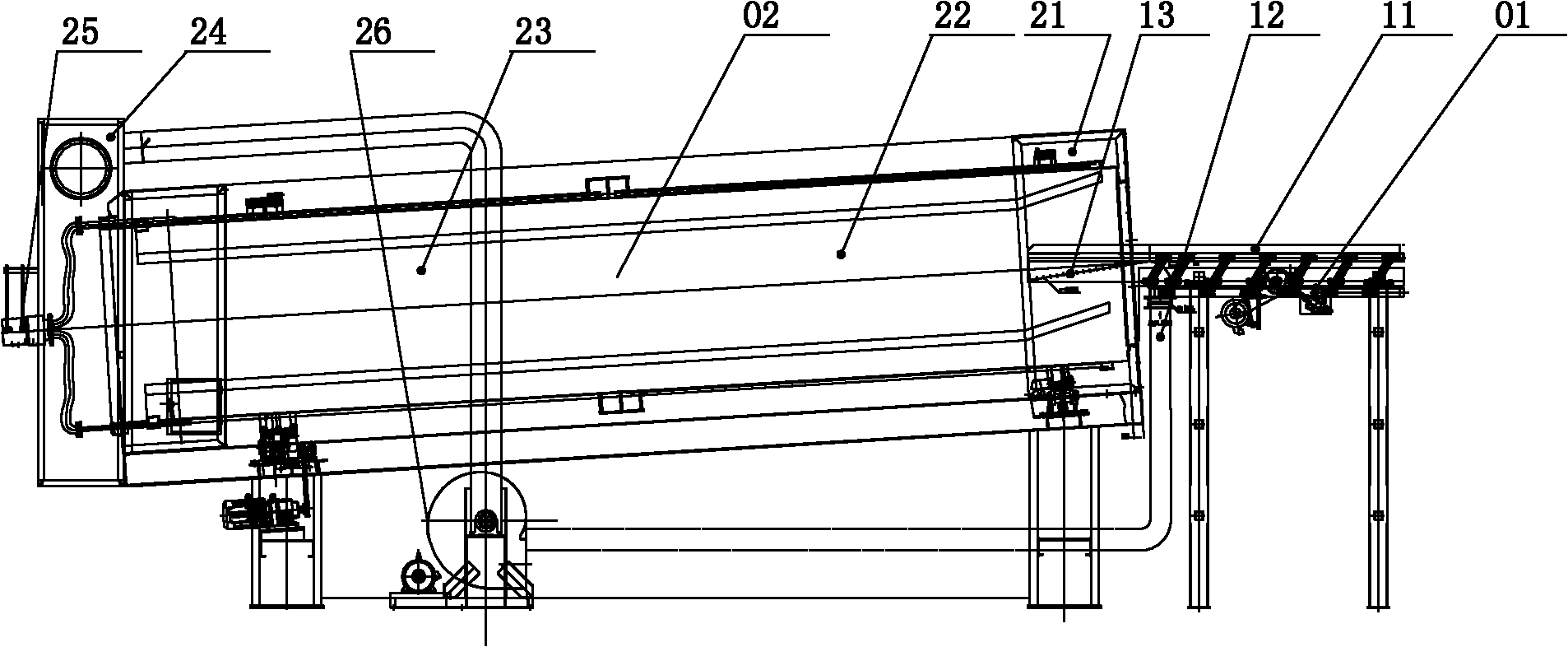

[0024] Such as figure 1 As shown, the device of the present invention is composed of two interconnected devices, including a vibrating fluidized bed 01 for feeding and preliminary drying of cut tobacco, and a drum dryer 02.

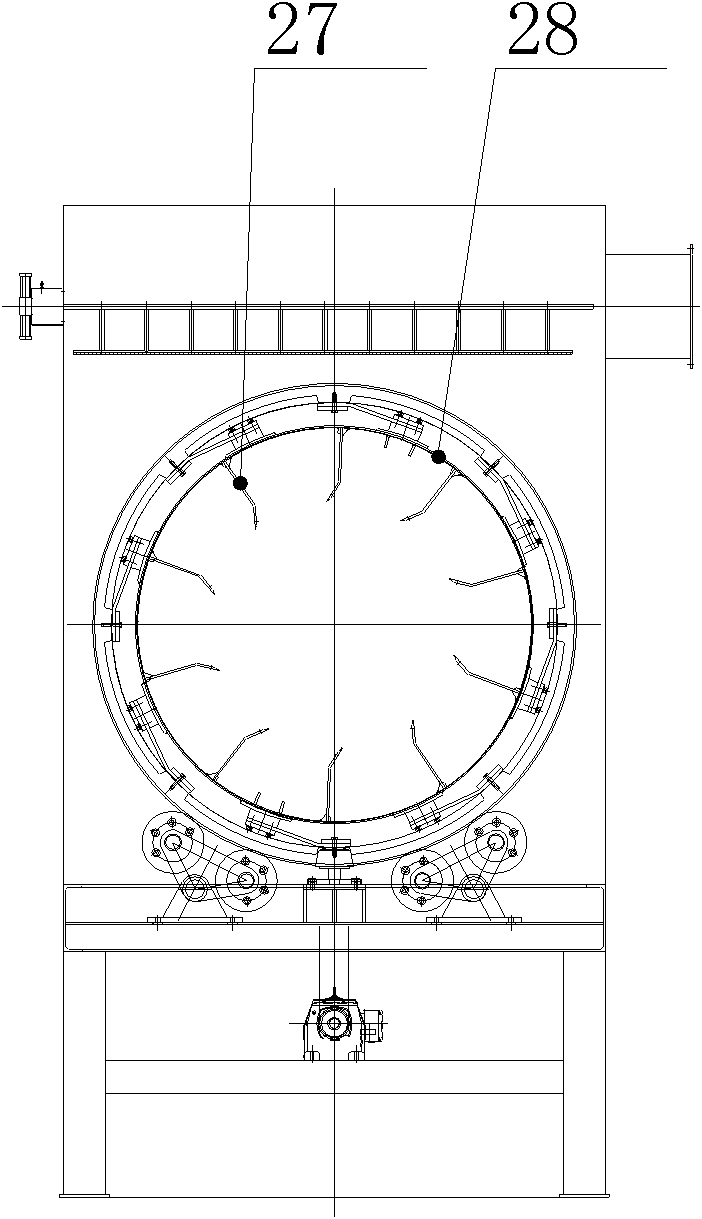

[0025] Such as figure 1 and figure 2 As shown, the drying cylinder of the tumble dryer 02 is divided into a high temperature section 22 and a low temperature section 23 according to the temperature difference along the cut tobacco feed and discharge direction. The high temperature section 22 and the low temperature section 23 are basically equal in length, and the high temperature section 22 is provided by steam as a heat source , The low temperature section 23 is provided with hot water as a heat source. The heating steam and hot water are respectively introduced into the high temperature drying section 22 of the drying cylinder 02 and the drying cylinder wall 28 of the low temperature section 23 through the rotary joint 25. 27 is heated.

[0026] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com