Shoe

A technology of resin and coating film, which is applied in the field of shoes, can solve the problems of cracks in the enamel layer and insufficient ozone resistance, and achieve the effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

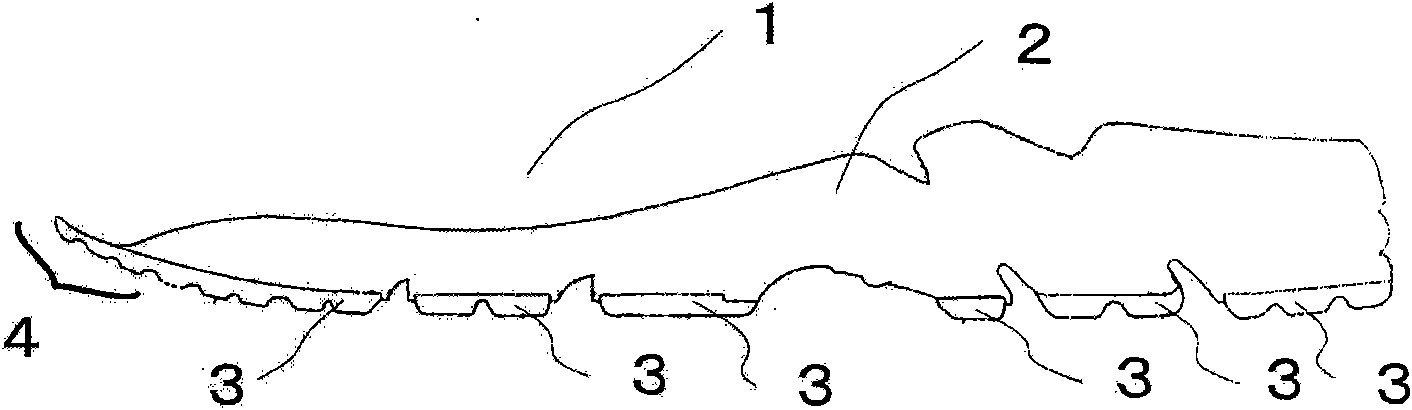

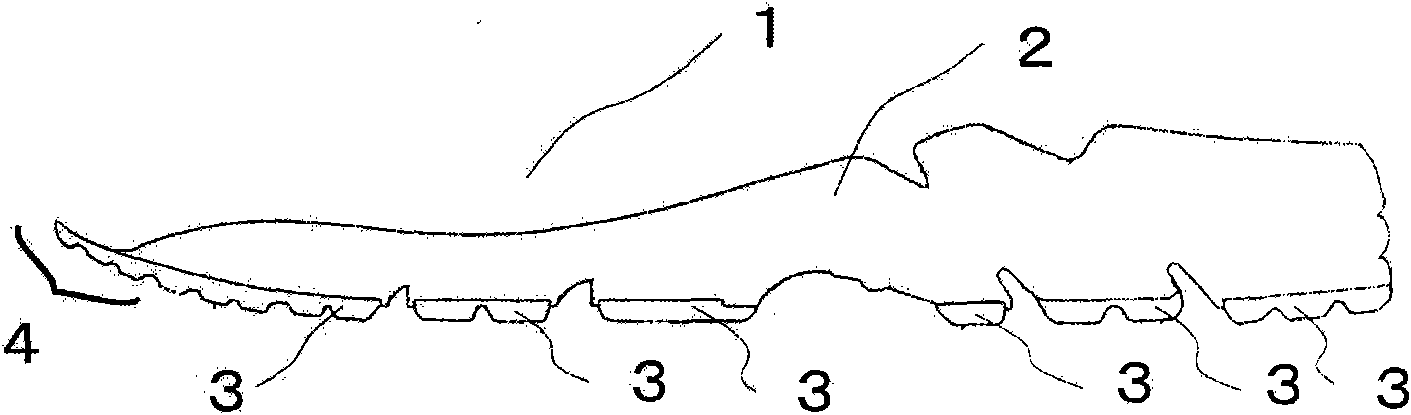

Image

Examples

Embodiment

[0065] A jogging type JM-242 (manufactured by アキレス Co., Ltd.) having an extended part of the outsole made of a mixed rubber of natural rubber and SBR at the toe part was produced.

[0066] The stretched part of the outsole stretched and rolled up at the toe part of the upper leather of the manufactured shoe was wiped with ethanol so that no dust and the like adhered thereto (degreasing treatment).

[0067] Coating solution 1: 100 parts by weight of polyurethane resin (resin solid content 30% produced by DIC Co., Ltd.)

[0068] 75 parts by weight of toluene

[0069] Cyclohexanone 75 parts by weight

[0070] Matting agent (manufactured by Hirono Chemical Industry Co., Ltd.) 30 parts by weight

[0071] Coating solution 2: 100 parts by weight of polyurethane emulsion (manufactured by Hirono Chemical Industry Co., Ltd. with 40% resin solid content)

[0072] 150 parts by weight of water

[0073] Prepare the above-mentioned solvent-based and water-based coating liquid, apply it t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com