Visual filter capable of automatically blowing gas and filtering method thereof

A gas filter and self-blowing technology, which is applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of unreasonable filter structure and poor effect, and achieve small internal volume, not easy to leak, and analysis The effect of short lag time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

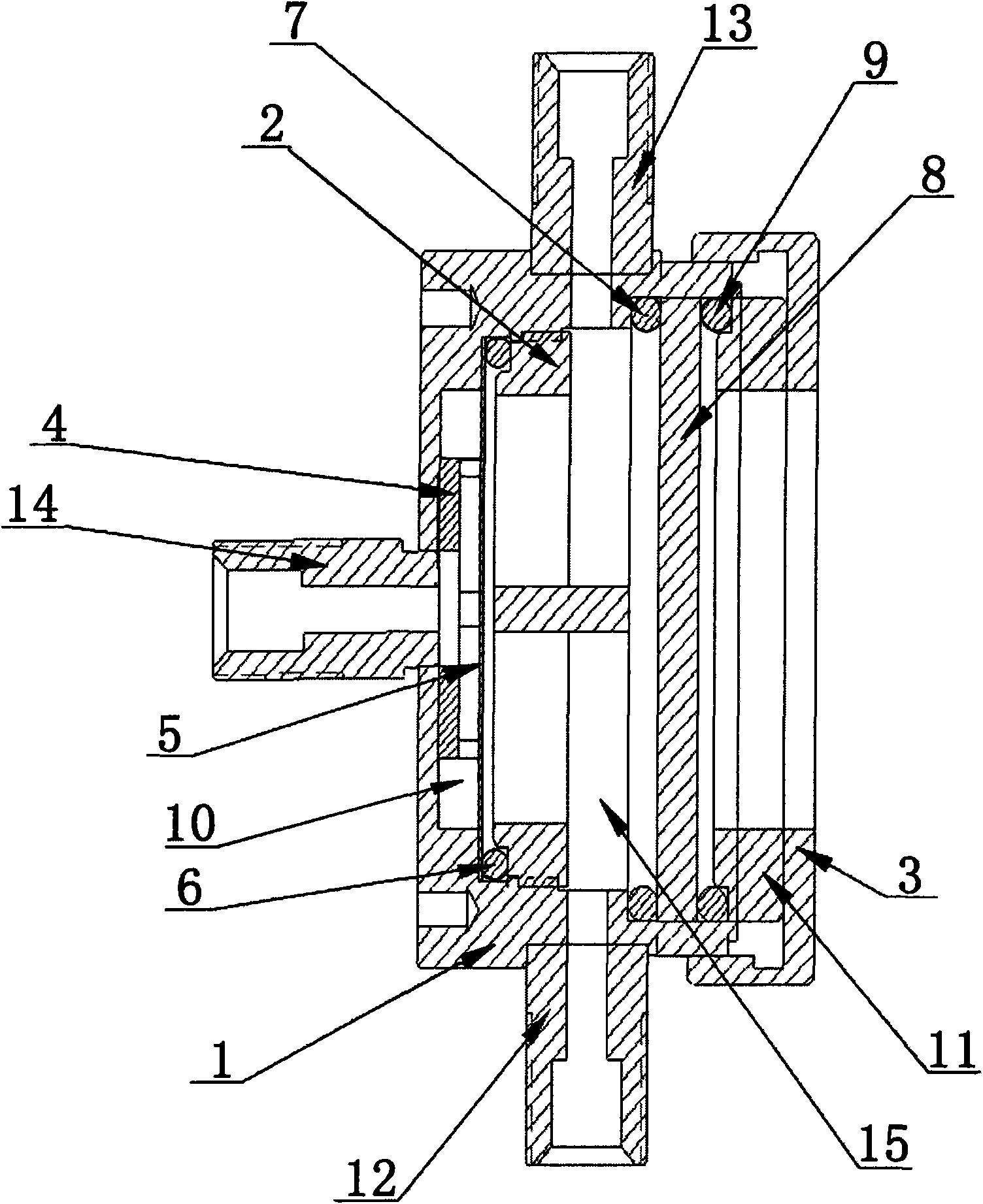

[0038] Examples see figure 1 As shown, this visible self-blowing gas filter includes a filter membrane 5 installed in the main cavity 1, and a filter chamber and a sample gas chamber separated on both sides of the filter membrane. There are sealing rings.

[0039] One end of the main cavity 1 is open, and the middle of the bottom plate at the other end is inserted with an outlet nozzle 14 communicating with the sample gas chamber 10. Inside the main cavity, a support block 4 and a filter membrane are sequentially installed from the bottom plate of the main cavity to the opening. Sheet 5, inner cover 2, glass window 8 and pressure ring 11.

[0040] The sample gas chamber 10 is surrounded by one side of the filter membrane, the bottom plate of the main cavity and the support block.

[0041] The filter chamber 15 is surrounded by the other side of the filter membrane, the inner cover 2 and the glass window 8 .

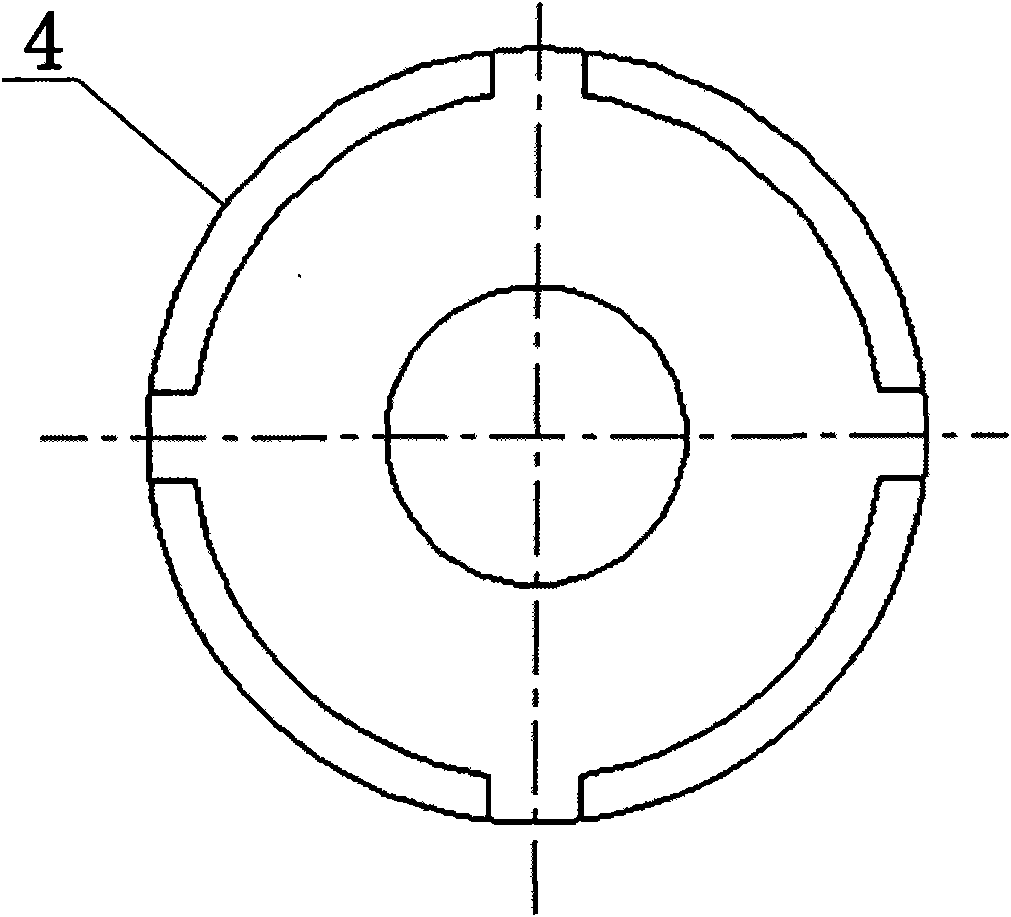

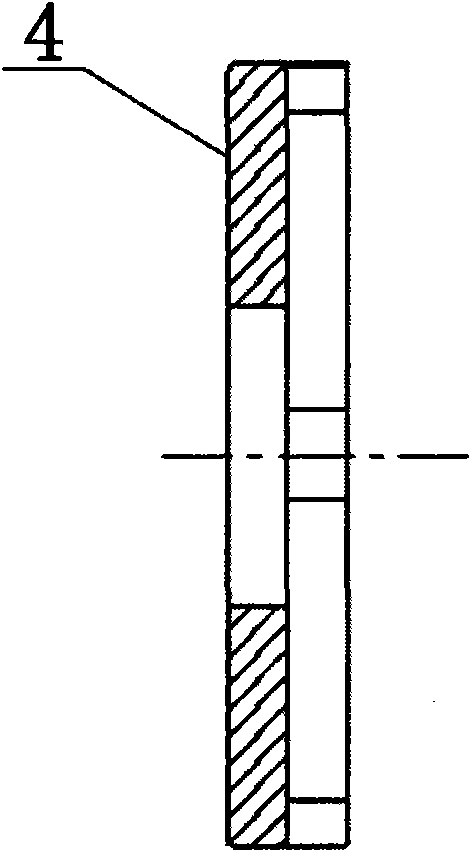

[0042] The filter membrane 5 is fixed in the main cavity, a suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com