Blade saw for cutting and manufacturing method thereof

A technology of blades and blades, which is applied in the field of cutting blade saws, can solve the problems of personal accidents of operators, small stones bouncing upwards, damage to debris, etc., and achieve the effects of improving safety, suppressing resonance, and satisfying safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments for carrying out the present invention will be described in detail below based on the drawings.

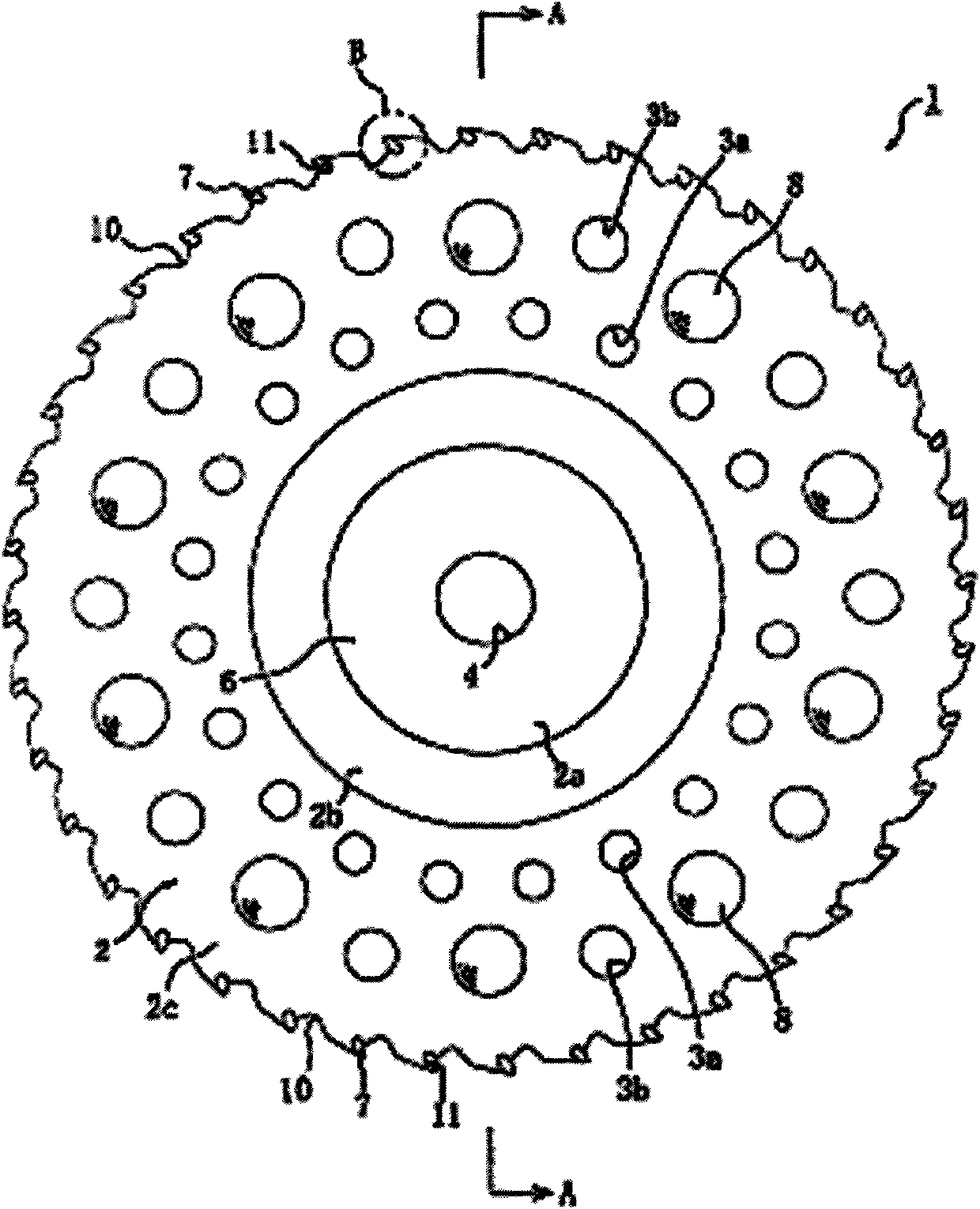

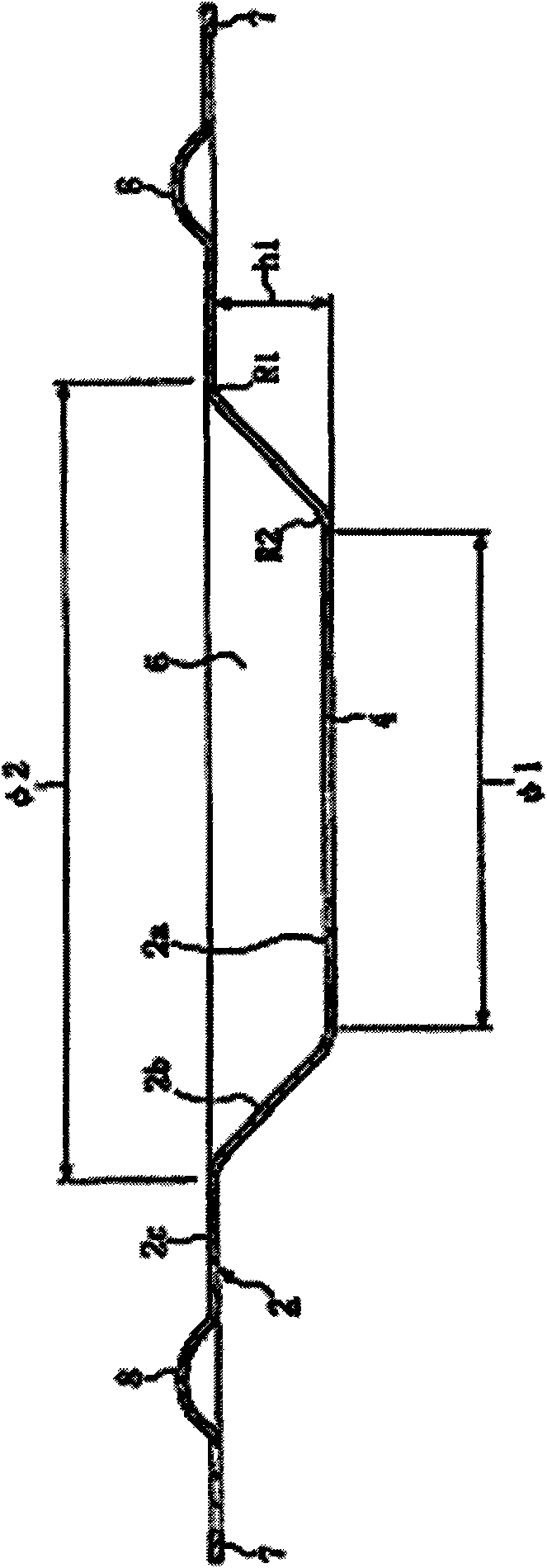

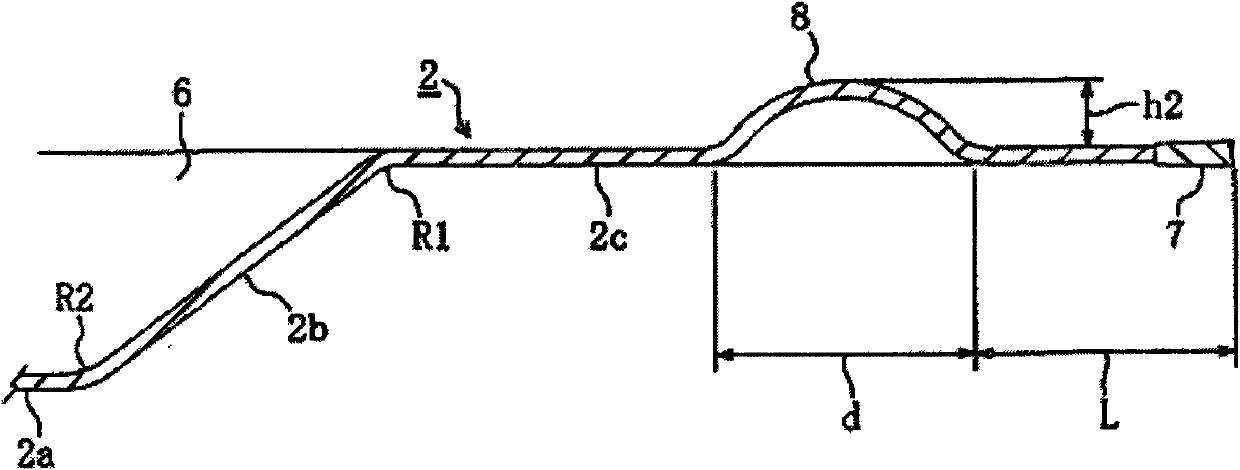

[0033] Figure 1 to Figure 5 This is an embodiment of the cutting blade saw according to the present invention. Such as Figure 1 ~ Figure 3 As shown, the blade saw 1 for cutting (referred to as the blade saw 1) is provided with a disc-shaped base metal disc 2 formed with a plurality of lightweight holes 3a, 3b, and at the center of the base metal disc 2 is formed a Mounting hole 4 for mounting to cutter 5.

[0034]In addition, the base metal plate 2 has a mounting flat portion 2a of a predetermined width formed outside the mounting hole 4; and a step portion 2b with a protrusion height h1 facing the side of the reverse cutter 5 is formed outside the mounting flat portion 2a. , At the same time, a blade flat portion 2c is formed outside the step portion 2b. Then, on the base metal plate 2, a circular space-shaped concave portion 6 is formed when viewed from ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap