Stably-operating continuous flow micro electrolytic reaction system

A stable operation, micro-electrolysis technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of unstable operation of reactors, low treatment efficiency, easy passivation of fillers, etc. problems, to achieve the effect of hardening and passivation, improving the removal effect and avoiding compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with specific embodiments.

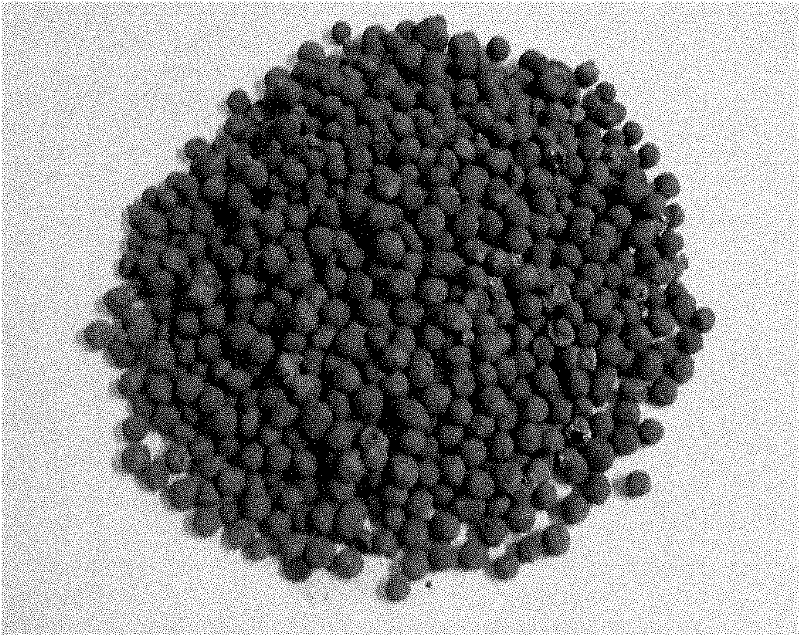

[0022] First, according to the preparation steps, first weigh the required raw materials, mix them thoroughly, add water and mix thoroughly, then use a ball forming machine to make small balls with a diameter of 2-5 mm, put them in an oven for drying, and finally roast to prepare micro-electrolysis as a filler The tested material has a porosity of 0.5-0.8 and a specific surface area of 0.4-1.0m 2 / g, the formula and process are detailed in the table below.

[0023] Table 1 Preparation formula and process table of micro-electrolysis materials

[0024]

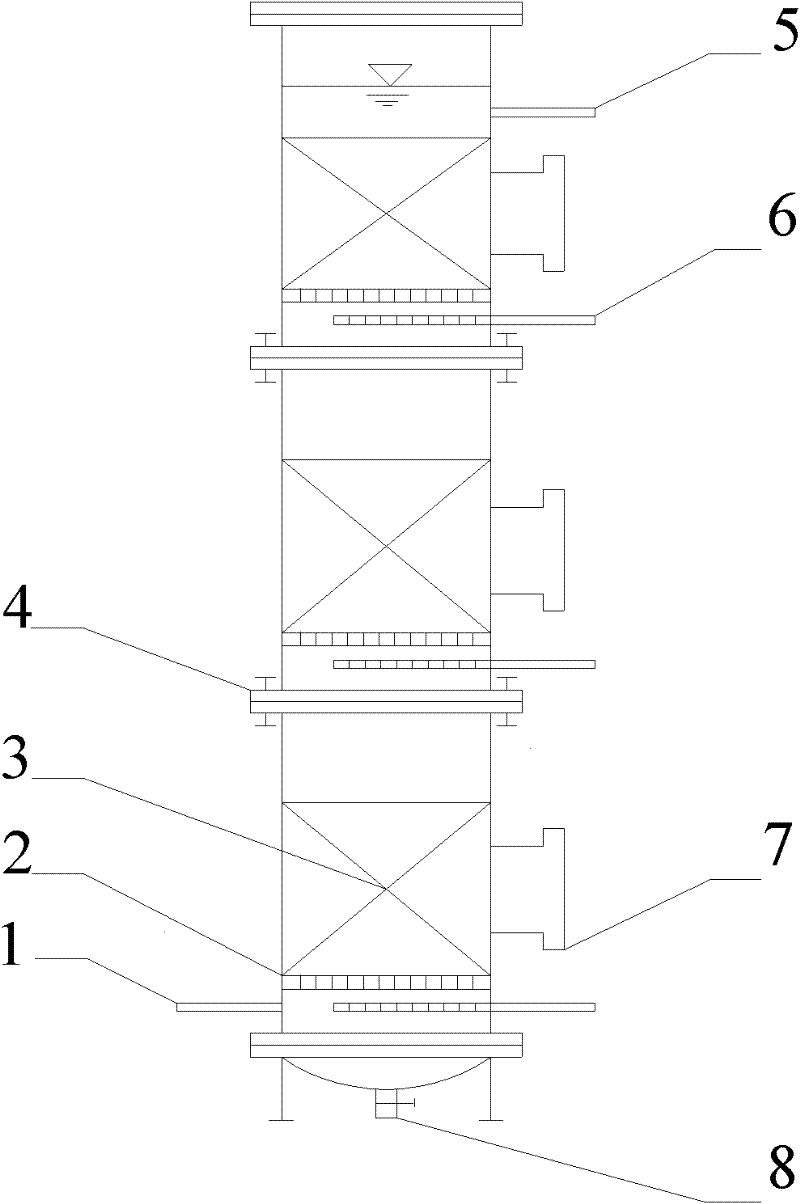

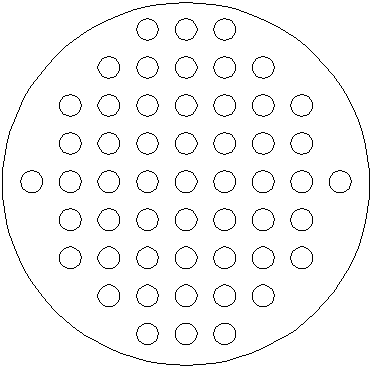

[0025] With figure 1 As an example, the embodiment of the present invention uses three micro-electrolysis reaction units connected in series to form a micro-electrolysis reaction system, including a feed port 1, a discharge port 5, and a slag discharge port 8. Each micro-electrolysis reaction unit is prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com