Reactive ion etching method for etching silicon

A technology of reactive ion etching and reaction, which is applied in the field of reactive ion etching and etching of silicon, can solve the problems of reducing etching efficiency, process fluctuations, and efficiency reduction, etc., to prolong the access time and reduce the Effect of Small Undercut Effect and Bowl Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

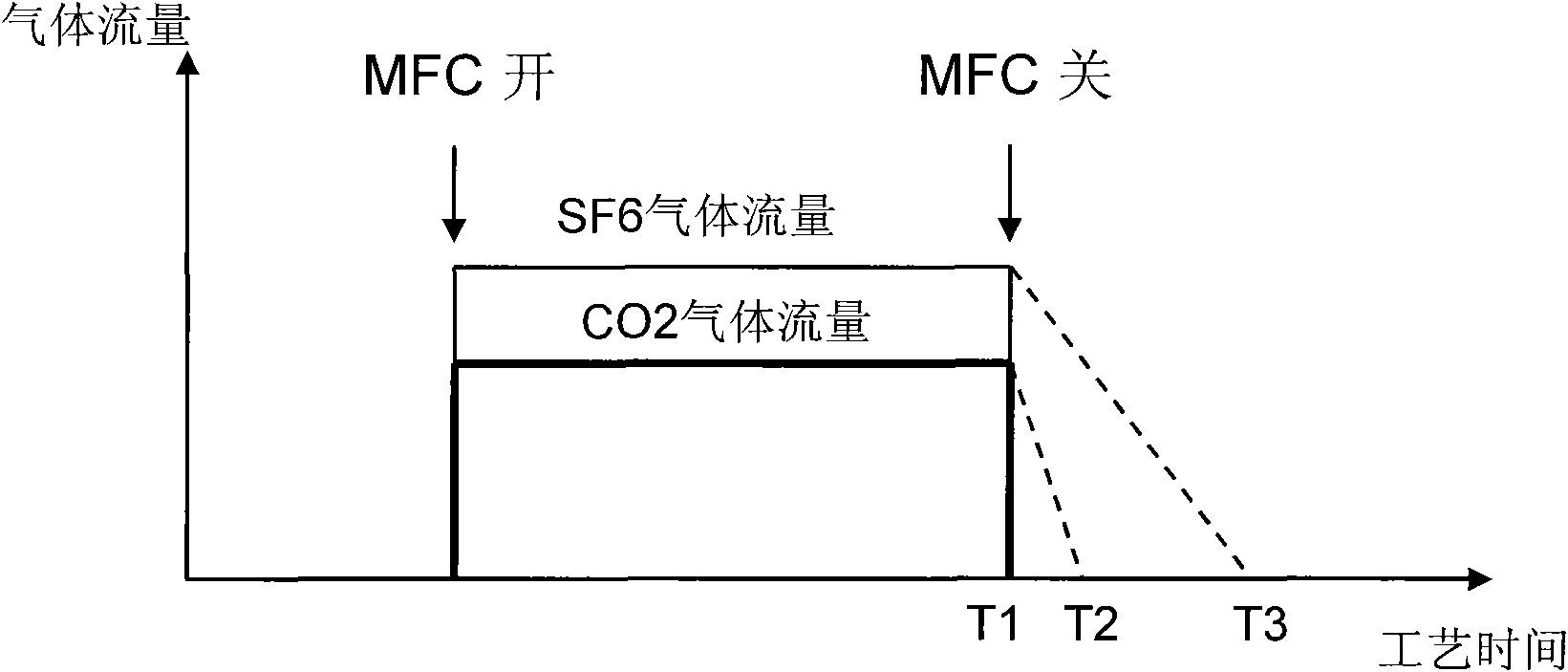

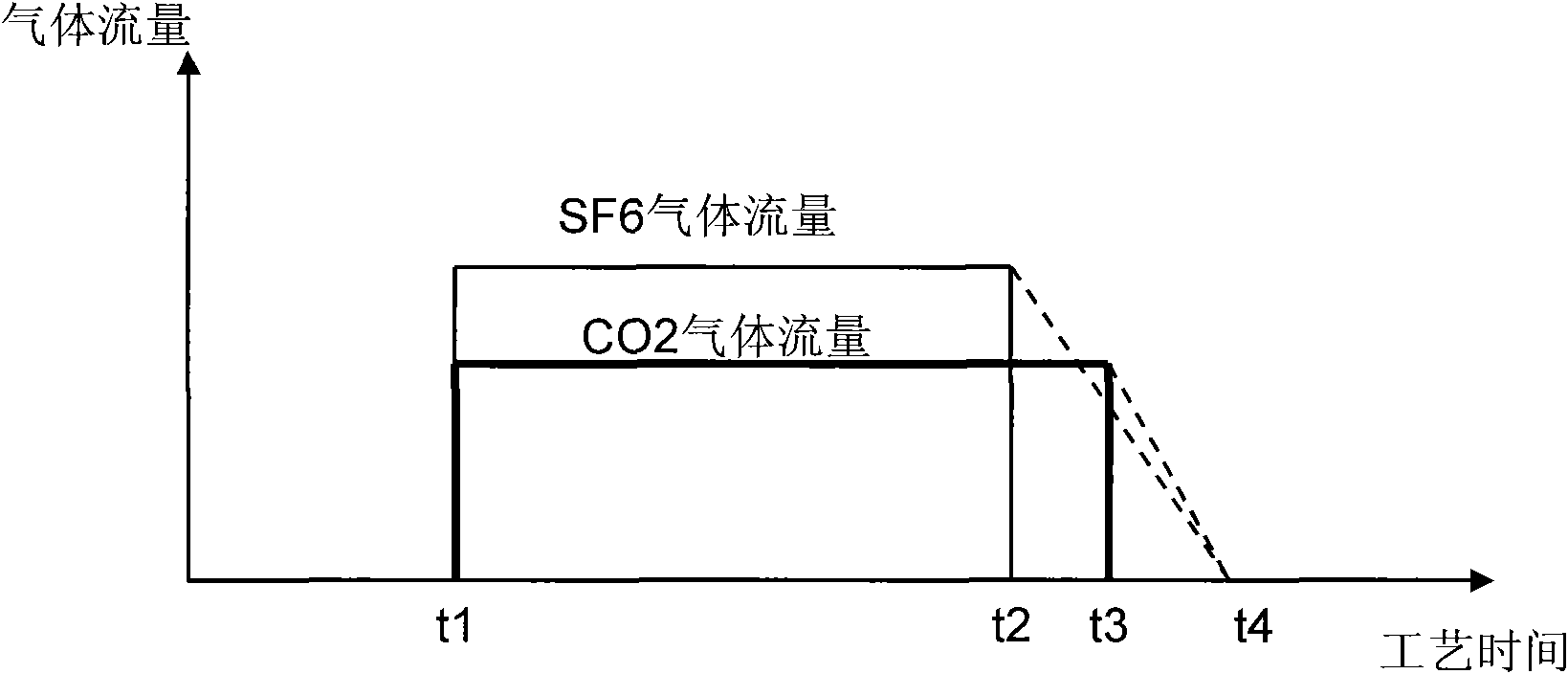

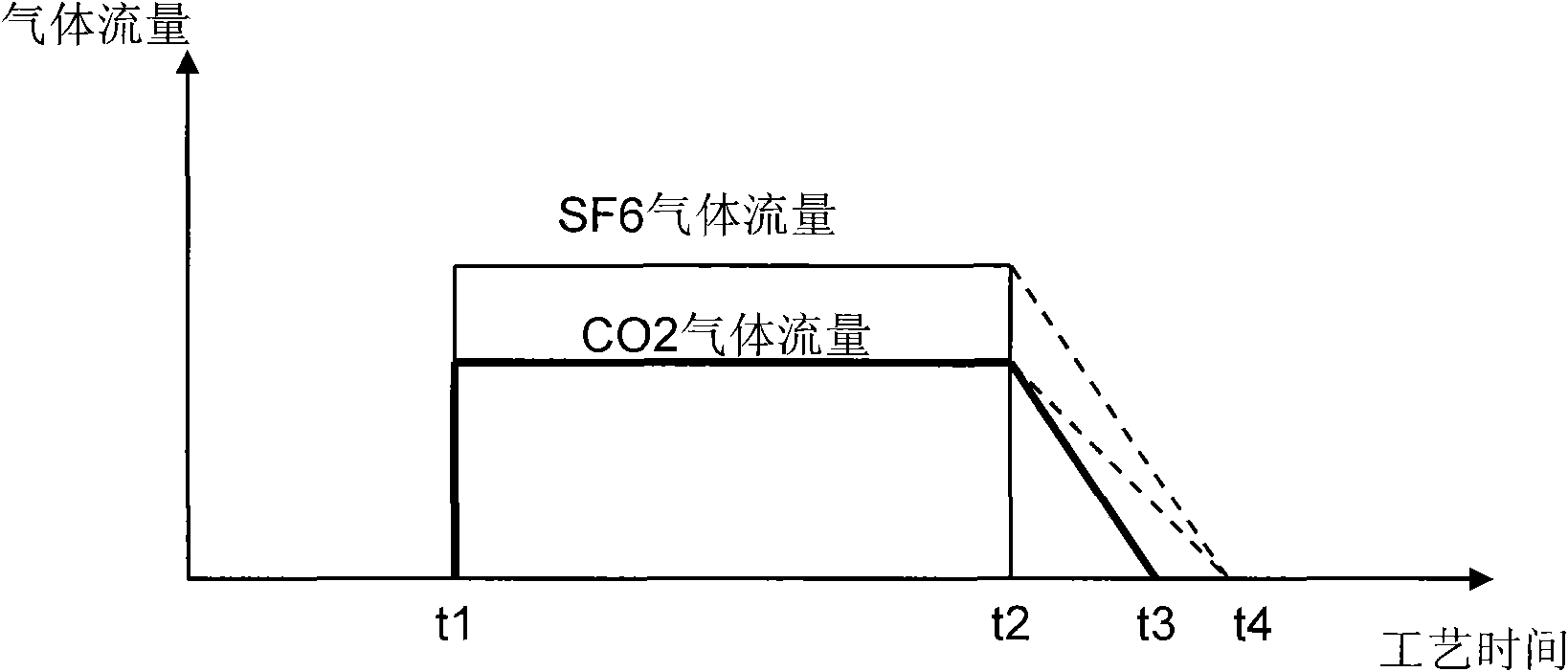

[0020] In this embodiment, taking the formation of TSV by reactive ion etching as an example, the depth of TSV reaches 50-200 μm, which is completed by the method of Steady-state deep silicon etch process. The reactive ion etching of this invention The method focuses on the control of the etching gas flow rate, therefore, other parameter settings of the reactive ion etching method, such as radio frequency (RF) power, air pressure, vacuum degree, etc., are not limited by the present invention. In this embodiment, during the etching process, the gas pressure ranges from 350 mTorr to 600 mTorr, the RF power is 1000 W, and the RF frequency is 60 MHz. In the steady-state deep silicon etching process, TSV etching is completed through multiple etching steps. In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com