Reaction chamber, deposition equipment and cleaning method suitable for remote plasma cleaning

A remote plasma and reaction chamber technology, applied in the field of semiconductor equipment, can solve problems such as structural component damage, and achieve the effects of reducing damage, avoiding component damage, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

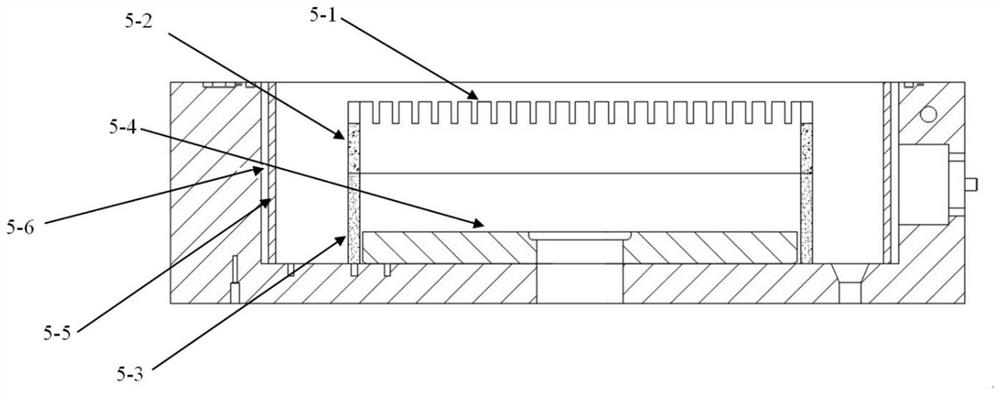

[0044] Embodiment 1 of the present invention provides a reaction chamber suitable for remote plasma cleaning, figure 1 A schematic structural diagram of a reaction chamber suitable for remote plasma cleaning according to Embodiment 1 of the present invention is shown, please refer to figure 1 , the reaction chamber includes:

[0045] cavity body;

[0046] The heating base 5-4 is arranged in the main body of the cavity.

[0047] The annular support member 5-3, the annular support member 5-3 surrounds the outer circumference of the heating base 5-4, the surface of the annular support member 5-3 facing the heating base 5-4 is the inner surface, and the surface facing the heating base 5-4 The surface of 4 is the outer surface, the roughness of the outer surface is greater than that of the inner surface, and the material of the annular support member 5-3 is ceramic.

[0048] The gas distribution grid 5-2 is arranged on the annular support member 5-3 and is located above the heat...

Embodiment 2

[0054] Embodiment 2 of the present invention provides a deposition apparatus, which includes the above-mentioned reaction chamber, and further includes: a plasma cleaning source chamber;

[0055] a cleaning pipeline, which is connected between the plasma cleaning source chamber and the reaction chamber;

[0056] The air source pipeline is connected to the cleaning pipeline.

[0057] Specifically, the plasma cleaning source chamber is used to generate excited plasma, and the generated plasma enters the reaction chamber through the cleaning pipeline to clean the interior of the reaction chamber. The gas source pipeline is used for supplying the reaction gas to the plasma cleaning source chamber, and feeding the purging gas into the cleaning pipeline, and the purging gas purifies the interior of the reaction chamber after cleaning the reaction chamber.

Embodiment 3

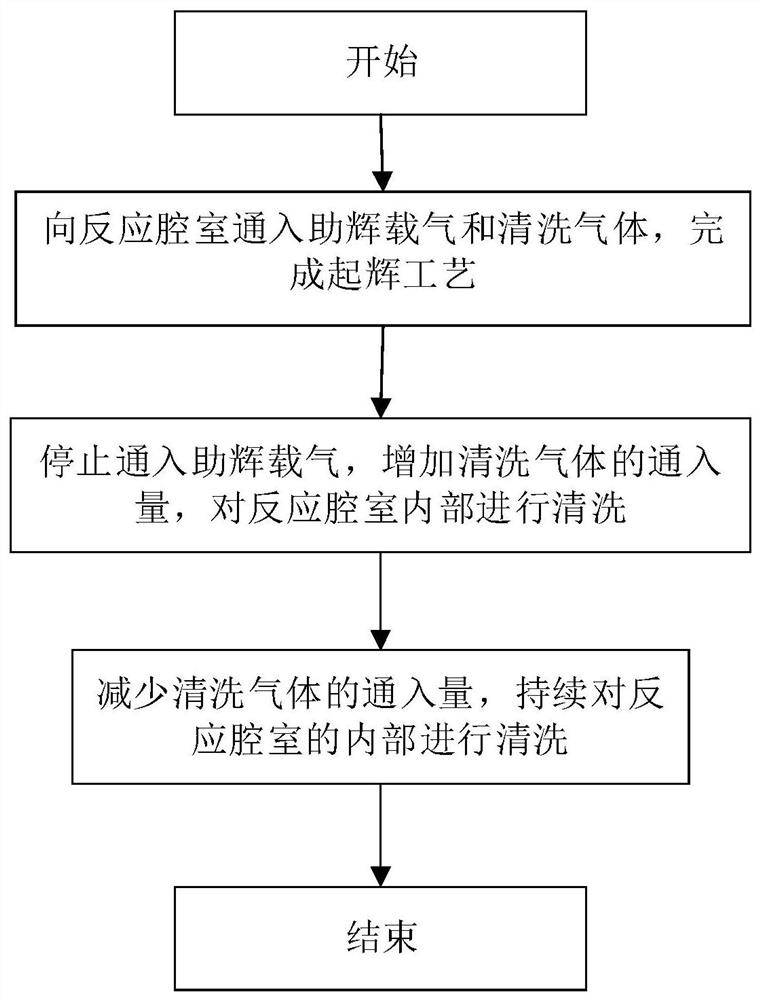

[0059] Embodiment 3 of the present invention provides a cleaning method for a deposition device, comprising the following steps:

[0060] Step 1: Pass the booster carrier gas and the cleaning gas into the plasma cleaning source chamber through the gas source pipeline, wherein the booster carrier gas is argon, so as to enhance the ignition in the plasma cleaning source chamber; The glow carrier gas and the cleaning gas are used to complete the ignition process.

[0061] Step 2: After the ignition process is completed, stop the introduction of the boosting carrier gas and increase the amount of cleaning gas. The cleaning gas is excited by the plasma cleaning source chamber to form plasma, and the plasma enters the reaction chamber through the cleaning pipeline , to clean the interior of the reaction chamber.

[0062] Step 3: reduce the flow of cleaning gas, and continuously clean the interior of the reaction chamber.

[0063] Specifically, in step 1, first, a booster carrier g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com