Dry connecting device

A connecting device, dry technology, used in covering/lining, building, building construction, etc., can solve the problems of unevenness, inconvenient connection operation, complex structure, etc., to achieve resistance to force and erosion, structural symmetry and stability, Stable and even force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

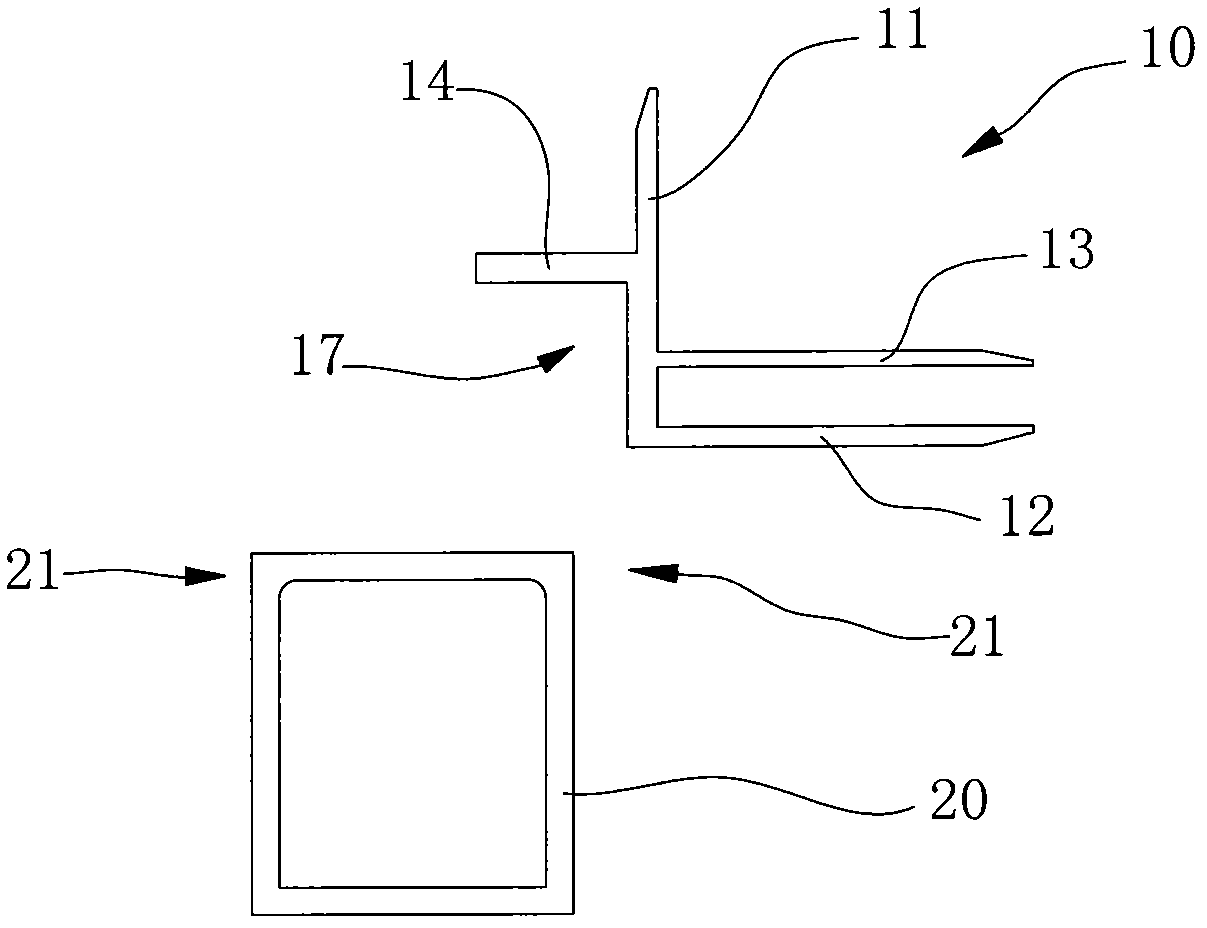

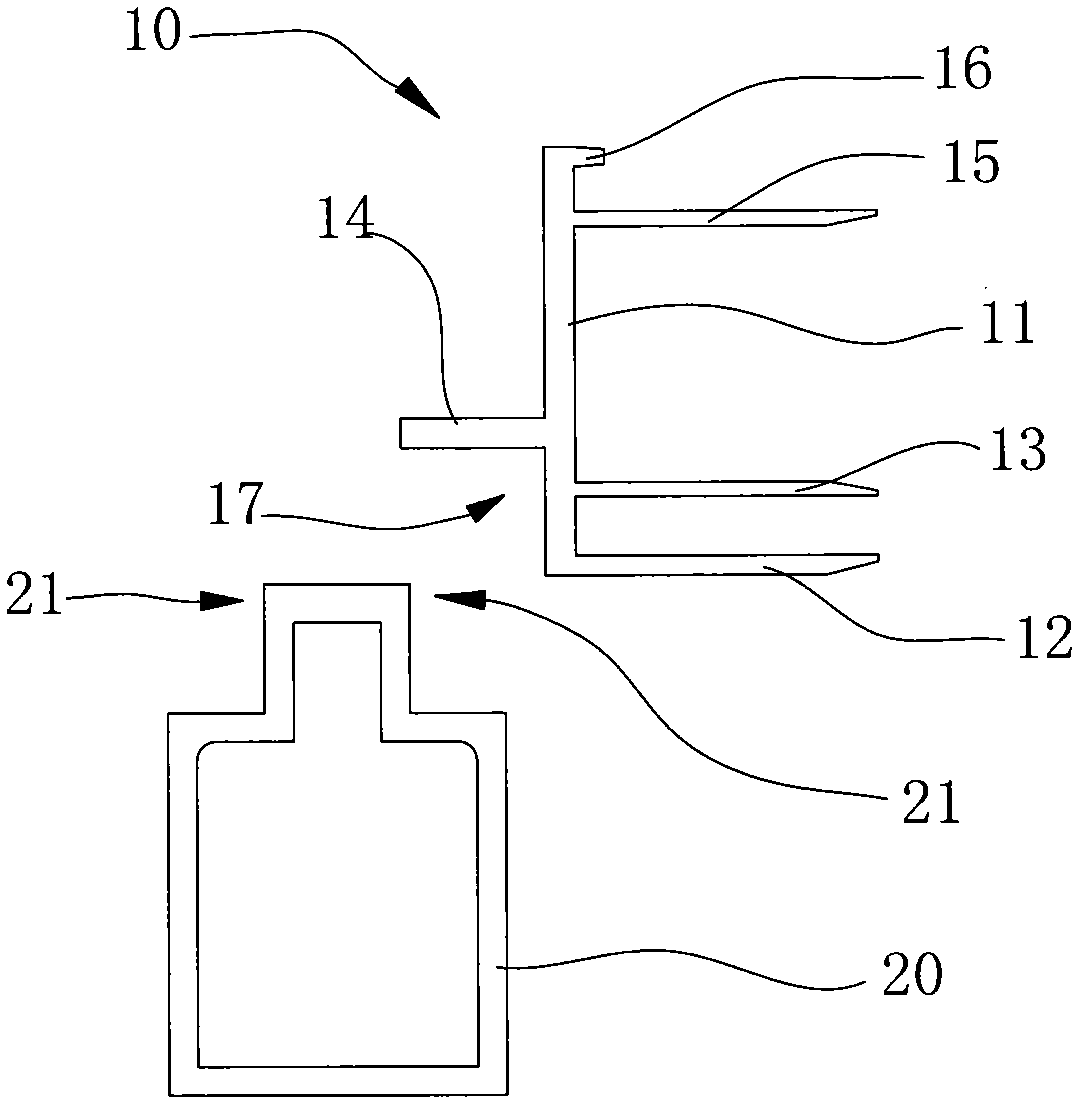

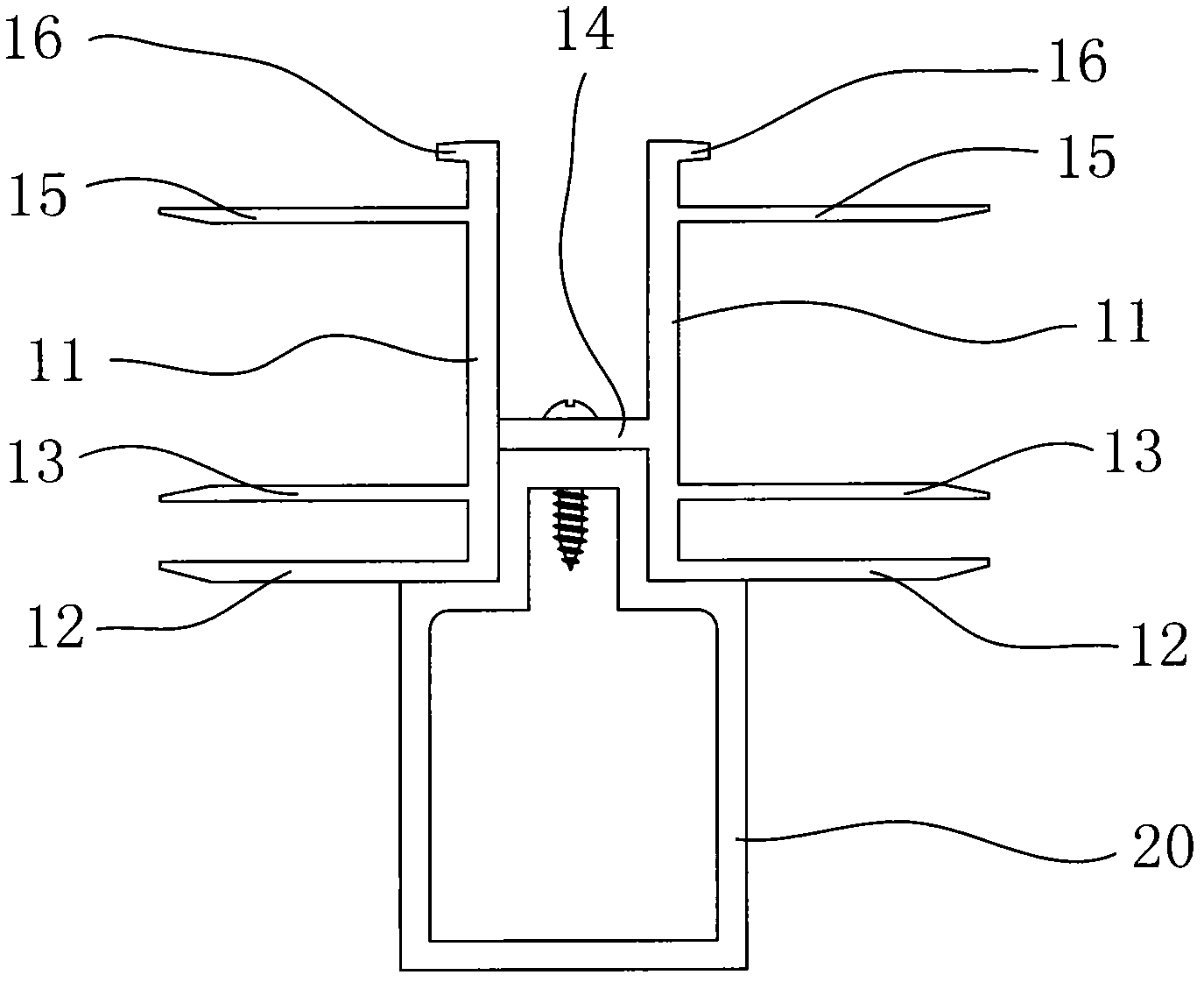

[0014] Such as figure 1 , 2 , 3, 7, and 8 show a dry connection device for thermal insulation boards, including a keel 20 and a fastener 10, the keel 20 is fixedly connected to the wall through a preset part 50, and the keel 20 is vertically positioned on the wall. And / or arranged in the horizontal direction, preferably arranged in the vertical and horizontal directions, the fastener 10 is inserted at the end of the insulation board, and then the fastener 10 is fixed to the keel 20, and the board seam is filled with filler 41 and sealant 42 filling, so that the connection between the insulation board and the wall is realized. The keel 20 of the present invention is provided with an angular portion 21 where two board surfaces intersect. The angular portion 21 includes a board surface parallel to the wall surface. The outer end surface of the fastener 10 is parallel to the wall surface, and the outer end surface forms an angled portion 21 with the adjacent plate surface near t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com